On-line cooling control method and device for improving strength and tenacity of high-frequency-welding (HFW) welded pipe after being hot rolled

A strong toughness, welded pipe technology, applied in the field of on-line controlled cooling to improve the strength and toughness of HFW welded pipes after hot rolling, can solve problems such as difficulty in ensuring cooling uniformity, achieve excellent comprehensive performance, reduce cooling rate gradient, and improve comprehensive mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Ф193.7×7.34mm HFW welded pipe (medium carbon steel material) is cooled online after hot rolling.

[0030] Chemical composition of HFW welded pipe (wt.%): C 0.30, Si 0.25, Mn 1.28, P 0.011, S 0.005, and the rest are Fe and uncontrollable inclusions. A c3 It is 830°C.

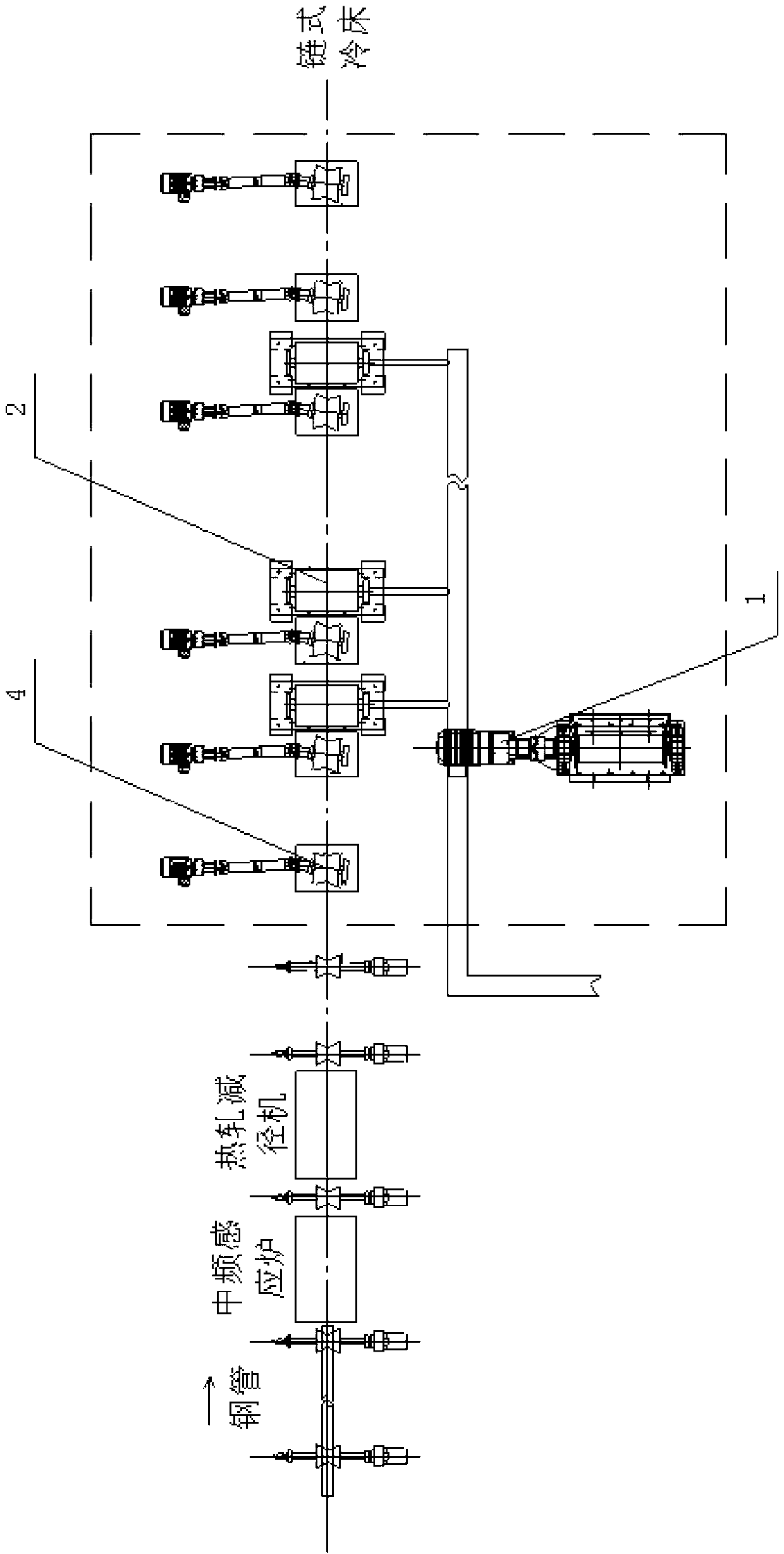

[0031] First, HFW welded pipes are hot rolled and reduced in diameter. The HFW welded pipe of Ф193.7×7.34mm is rapidly heated to 1000°C by an intermediate frequency heating furnace, and then enters the thermal tension reducing unit for hot rolling and reduces the diameter to a tube blank of Ф139.7×7.72mm, and then enters the rotary hot saw to saw it into a fixed length Steel pipes of about 10m.

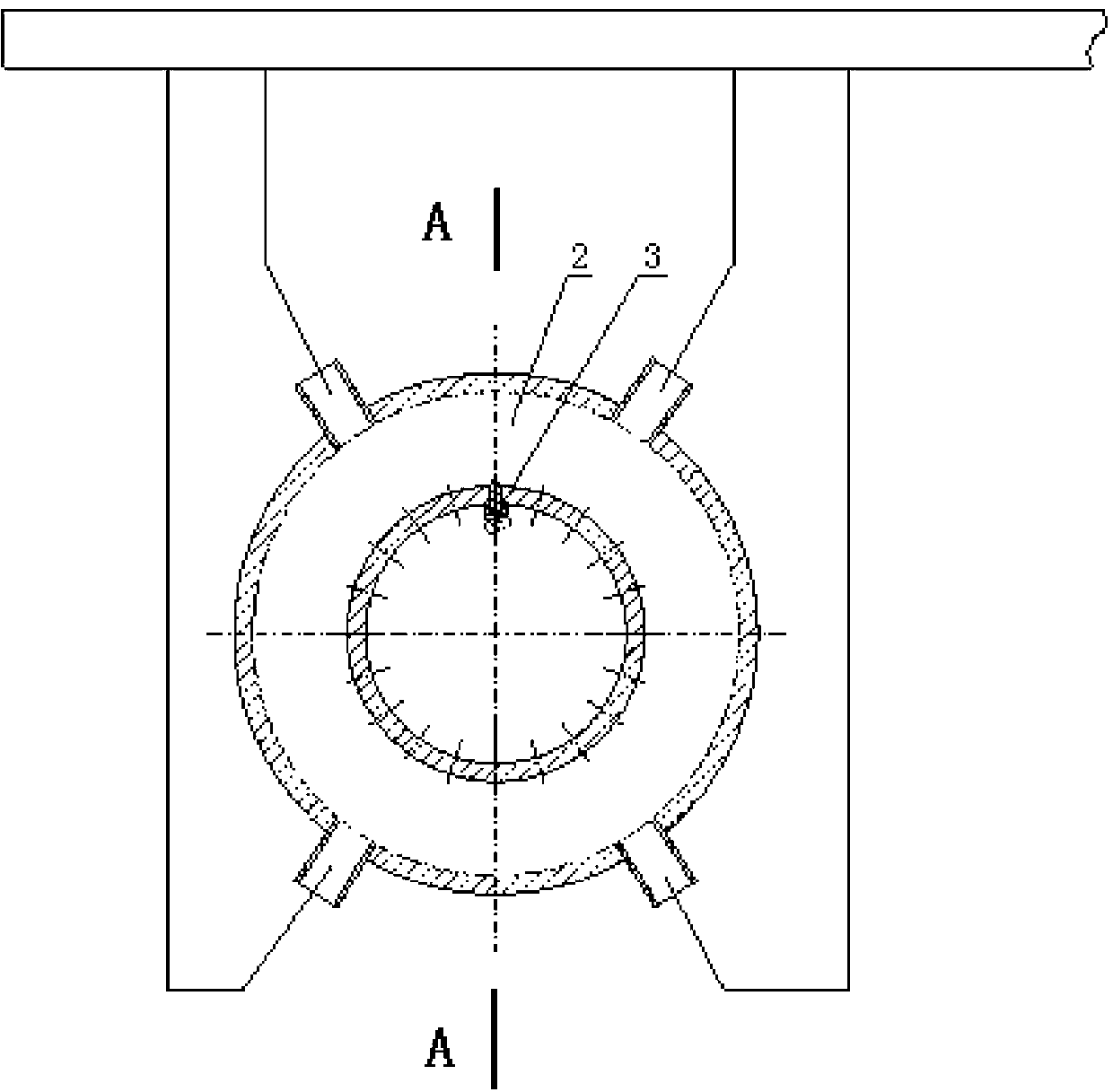

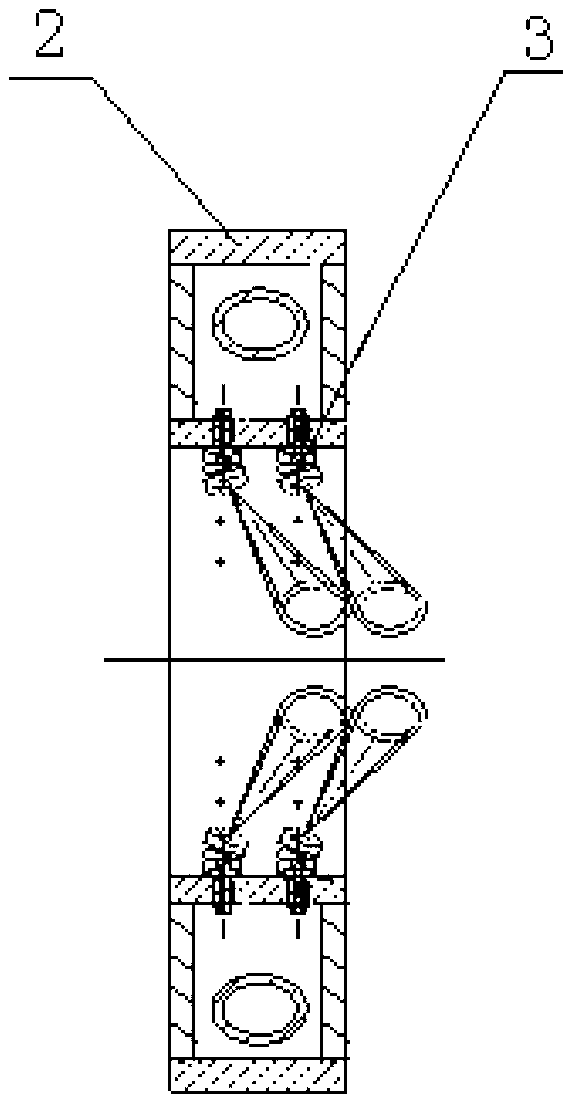

[0032] Secondly, the hot-rolled tube billet is cooled online. The temperature of the steel pipe after hot sawing is 880°C. It passes through a section of air-cooled roller table at a speed of 0.93m / s to reduce the temperature to 820°C, and then enters the V-shaped inclined roller table to make the s...

Embodiment 2

[0035] Example 2: Ф193.7×5.51mm HFW welded pipe (low carbon steel Q345 material) is cooled online after hot rolling.

[0036] Chemical composition of HFW welded pipe (wt.%): C 0.16, Si 0.26, Mn 1.31, P 0.013, S 0.004, and the rest are Fe and uncontrollable inclusions. A c3 It is 840°C.

[0037] First, HFW welded pipes are hot rolled and reduced in diameter. The HFW welded pipe of Ф193.7×5.51mm is rapidly heated to 980°C by an intermediate frequency heating furnace, and then enters the thermal tension reducing unit for hot rolling and reduces the diameter to a tube blank of Ф139.7×6.20mm, and then enters the rotary hot saw to saw it into a fixed length Steel pipes of about 10m.

[0038] Secondly, the hot-rolled tube billet is cooled online. The temperature of the steel pipe after hot sawing is 860°C. It passes through a section of air-cooled roller table at a speed of 1.08m / s to reduce the temperature to 795°C, and then enters the V-shaped inclined roller table to rotate th...

Embodiment 3

[0041] Example 3: Rapid cooling and quenching process of HFW welded pipe after hot rolling. For small-sized, thin-walled and thick steel pipes after hot-stretching, if the water flow and pressure are increased, when the cooling rate is ≥50°C / s (the maximum cooling rate can reach 90°C / s), online quenching after hot-rolling of HFW welded pipes can be realized The ability to provide a new process approach for the development of lower cost and higher steel grade HFW welded pipes in the future.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com