Air-water mist cooling system for continuous annealing of strip and control method

A water mist cooling and air technology, applied in the field of metallurgy, can solve the problems of poor stress relief effect, uneven cooling, easy deformation, etc., to achieve the effect of stress relief, ensure cooling uniformity, and reduce deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

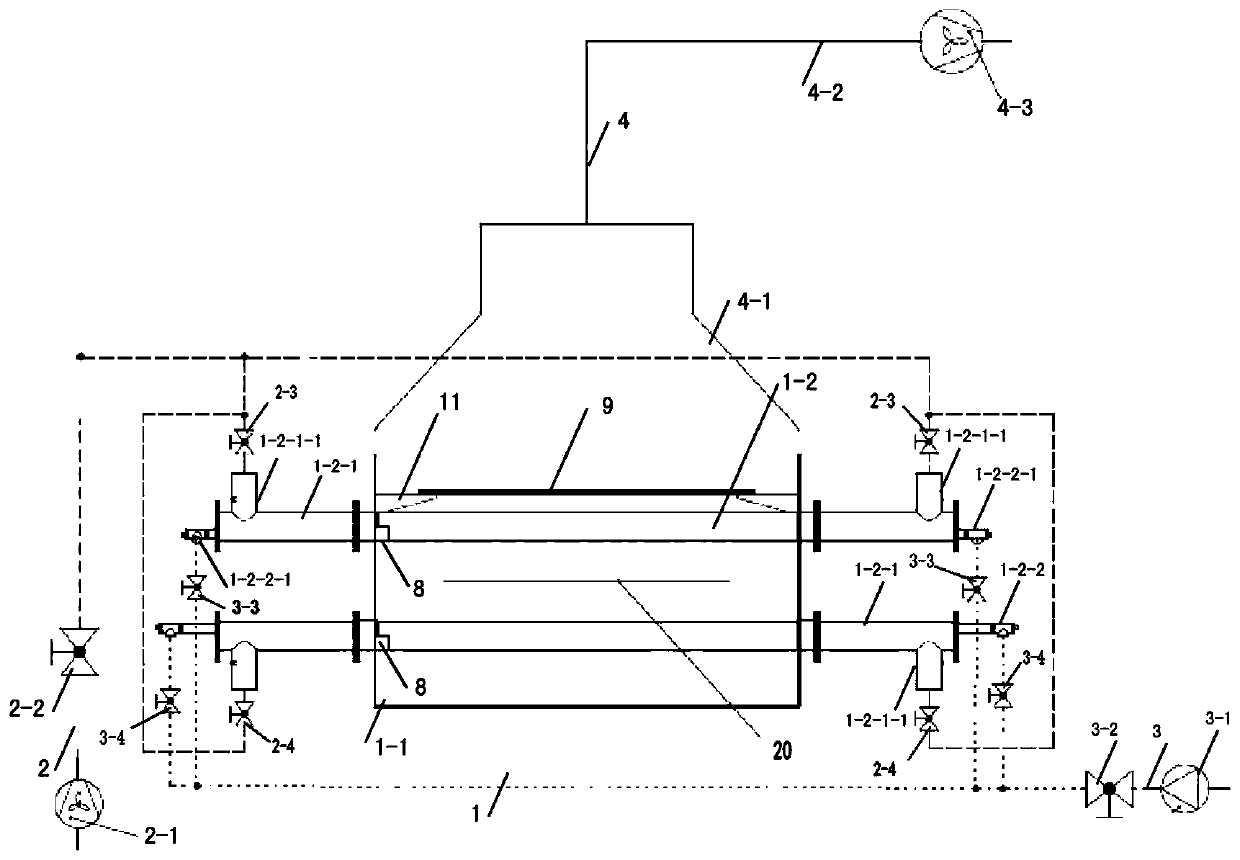

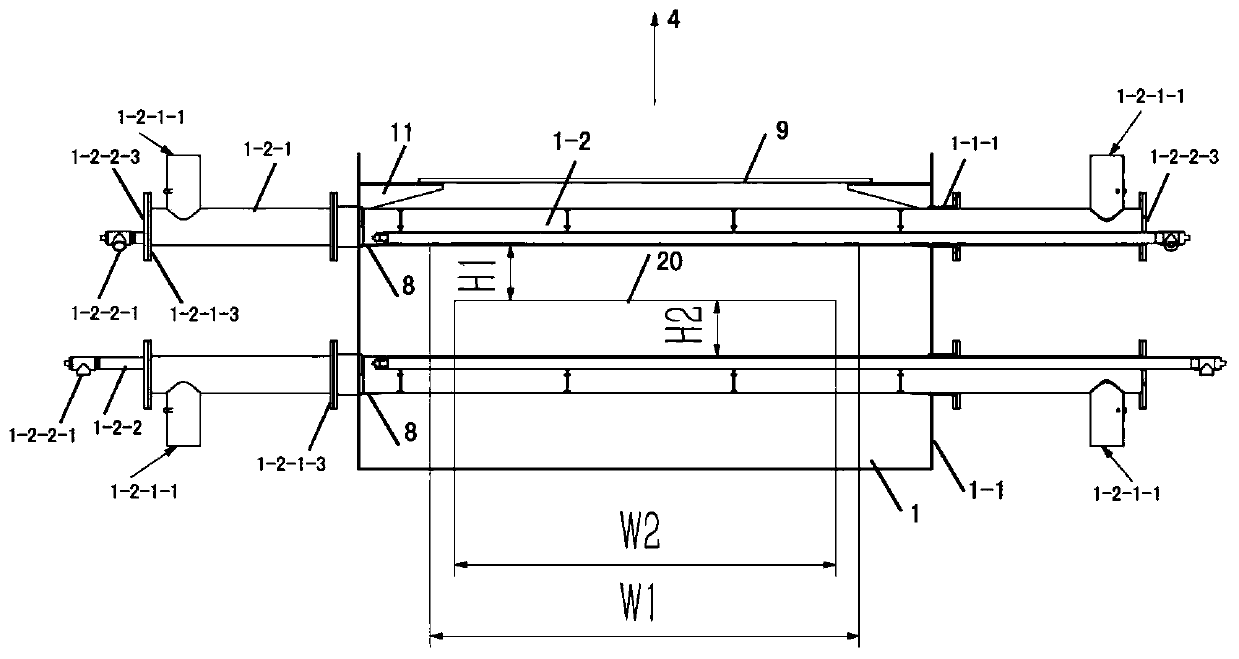

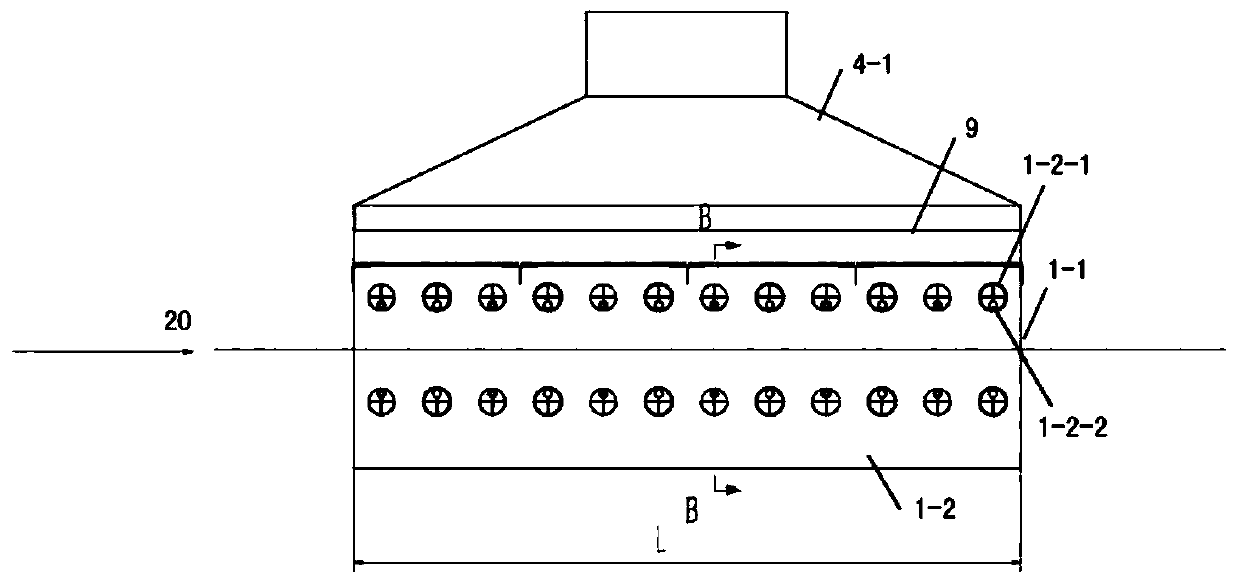

[0042] refer to Figure 1-Figure 4 , the air water mist cooling system for strip continuous annealing that specific embodiment 1 of the present invention relates to, comprises air water mist cooling device 1, blast device 2, water supply device 3 and exhaust device 4, air water mist cooling device 1 It includes a box body 1-1 and multiple sets of air and water mist injectors 1-2 built in the box body 1-1. The box body 1-1 is arranged at the strip continuous annealing cooling station, and each set of air and water mist injectors 1-2 has two, which are distributed up and down in the box 1-1, forming a facing upper and lower air and water mist spray structure, that is, forming a double-sided uniform multi-point surface spray from top to bottom and bottom to top Structure; the top of the box body 1-1 is provided with an air outlet, and the exhaust device 4 is at the air outlet to form a forced exhaust structure to discharge the hot air and water vapor in the box body 1-1 from the ...

specific Embodiment 2

[0053] See Figure 5 , Figure 6 , the air water mist cooling system for strip continuous annealing involved in the specific embodiment 2 of the present invention, its structural feature is: multiple groups of air water mist injectors 1-2 are arranged equidistantly and horizontally in a row along the direction of strip running cloth and fixed in the box body 1-1, and the upper and lower air and water mist sprayers 1-2 are arranged in a staggered position with strips. All the other are with specific embodiment 1.

[0054] The air water mist cooling control method for the strip continuous annealing that the present invention relates to is characterized in that:

[0055] 1) An air water mist cooling system is provided, the air water mist cooling system includes an air water mist cooling device 1, a blower device 2, a water supply device 3 and an exhaust device 4, and the air water mist cooling device 1 includes a box body 1-1 and A plurality of sets of air and water mist injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com