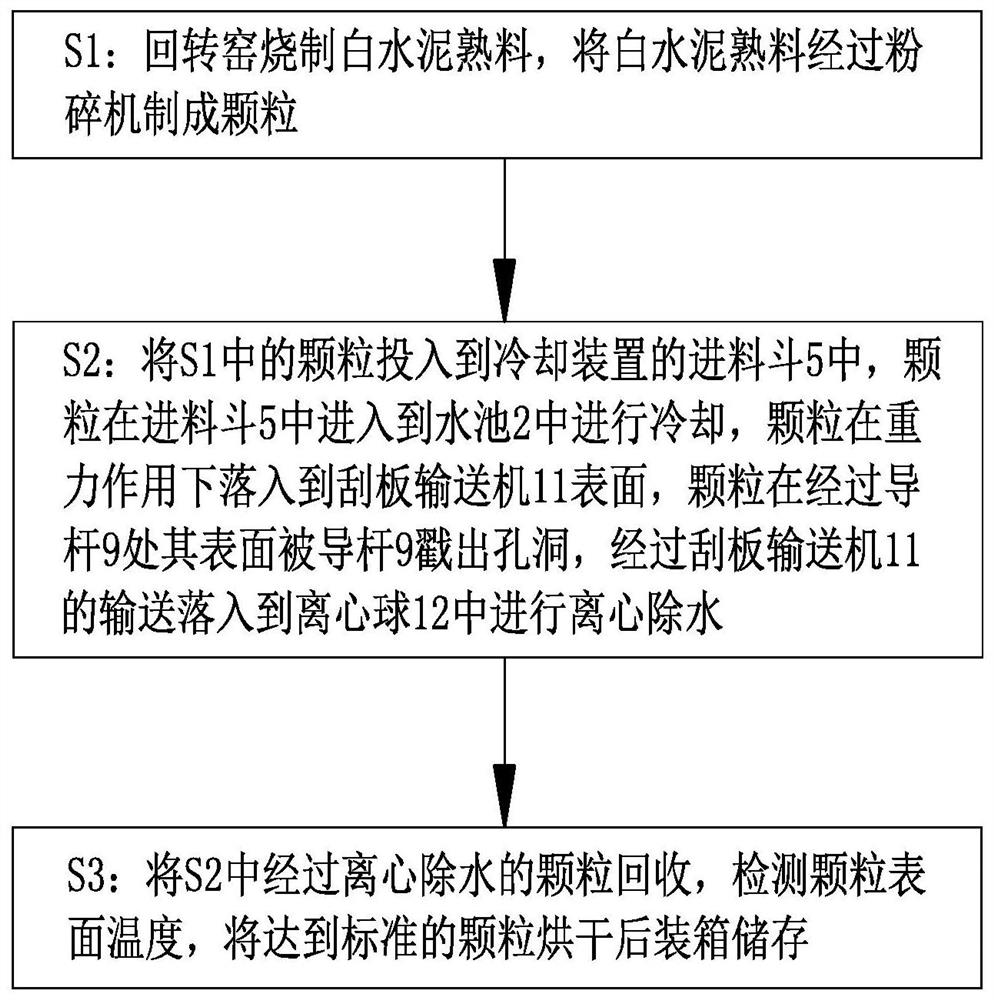

White cement clinker bleaching process

A technology for white cement and clinker, which is used in drying solid materials, granular materials, and processing discharged materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

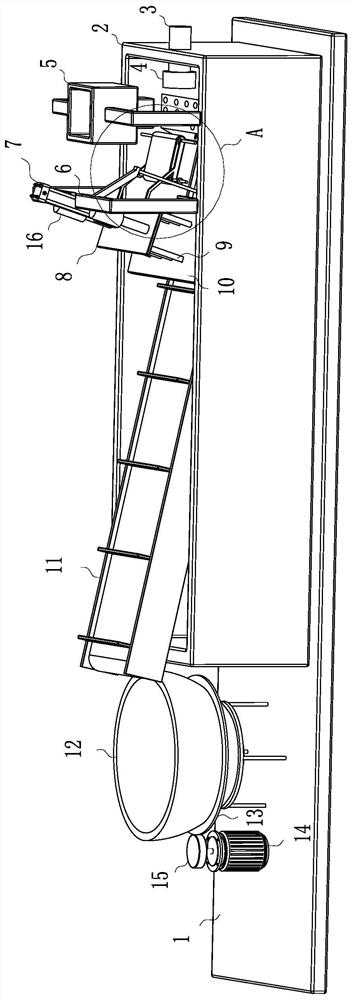

Examples

Embodiment approach

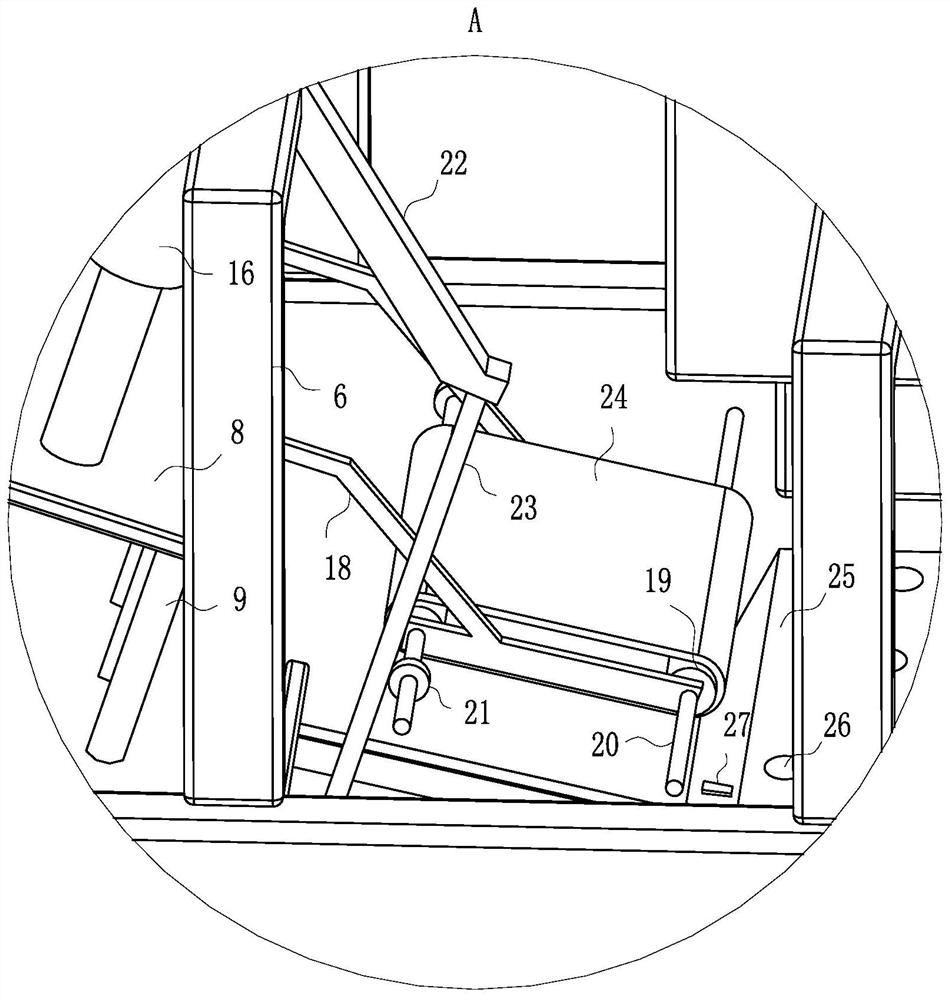

[0033] As a specific embodiment of the present invention, two mounting plates 18 are fixed on the rectangular plate 8, and two rollers 19 are rotatably installed between the two mounting plates 18. A connecting rod 20 is fixed, a worm wheel 21 is fixed at one end of the connecting rod 20 near the rectangular plate 8, a connecting plate 22 is fixed on the support 6, a worm 23 is fixed on the connecting plate 22, and the worm wheel 21 and the worm 23 are mutually meshing, a belt 24 is movably installed between the two rollers 19, the outer ring of the belt 24 is provided with bristles, and the bristles are used to smooth the clinker; when in use, because the scraper conveyor 11 is arranged obliquely , the clinker particles are easy to accumulate under the action of gravity on the scraper conveyor 11, thereby affecting the punching effect of the guide rod 9; by being provided with a worm 23, the worm 23 is driven to move when the rectangular plate 8 moves up and down, Make the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com