A single-point test device for impact pressure in the cooling zone of rolling steel and its test method

A shock pressure, single-point testing technology, applied in shock pressure measurement and metallurgy field, can solve the problems of limited operating space, uncertain size and uniformity of shock pressure, difficulty in pressure testing, etc. the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

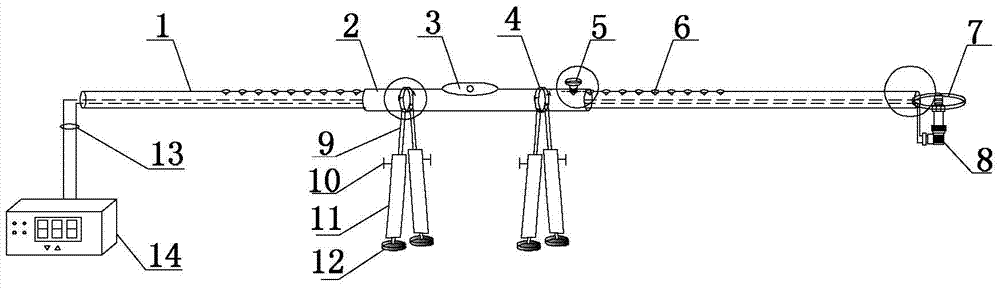

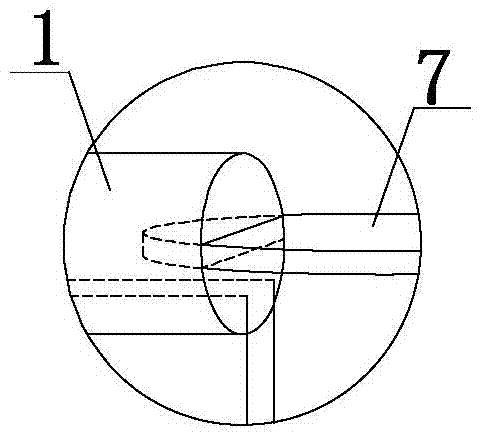

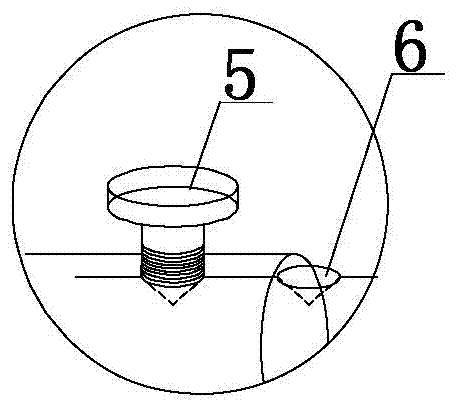

[0020] This embodiment is a single-point test device for impact pressure in the cooling zone of steel rolling, with a structure such as Figure 1-4 As shown, including fixing rod 1, fixing sleeve 2, spirit level 3, detachable bracket fixing ring 4, positioning screw 5, positioning hole 6, pressure transmitter fixing plate 7, pressure transmitter 8, bracket 9, fixing bolts 10. Bracket casing 11, weighted bracket base 12, wire 13, and display instrument 14. Both the fixed rod 1 and the fixed sleeve 2 are hollow tube structures, and the fixed rod 1 is uniformly drilled with positioning holes 6 along a straight line along its length direction. There is a distance between each positioning hole. There is a first fixing hole with an internal thread corresponding to the positioning hole 6, the fixing rod 1 passes through the fixing sleeve 2, and is fixed with the fixing sleeve 2 by the positioning screw 5 through the first fixing hole and the positioning hole 6; the level meter 3 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com