Hollow cathode central axial powder-feeding plasma spraying gun

A technology of axial powder feeding and hollow cathode, which is applied in the direction of plasma welding equipment, arc spraying, spraying devices, etc., can solve the problems of arc voltage fluctuation, arc heating efficiency reduction, particle state parameter dispersion, etc. Good stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

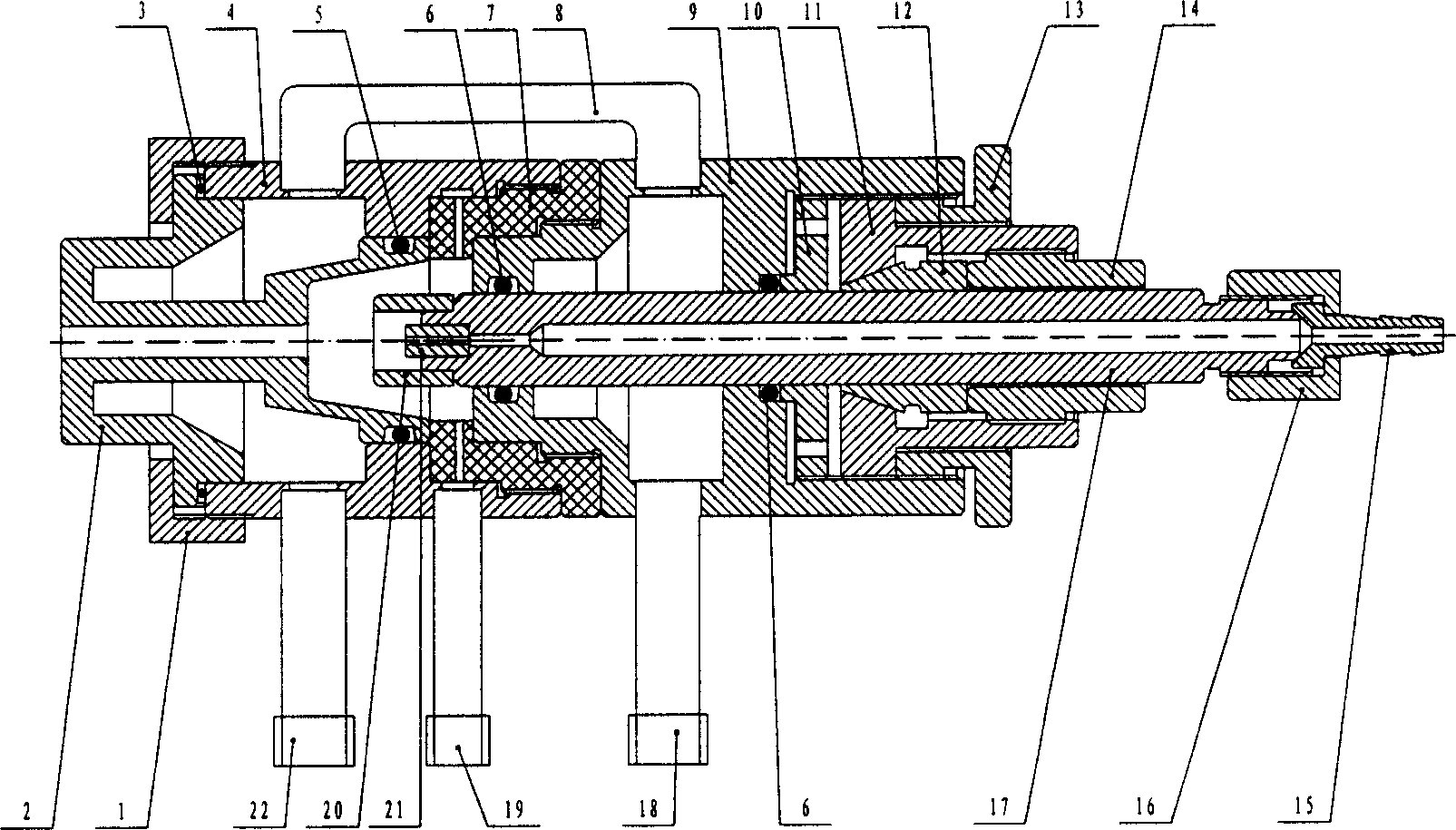

[0045] see figure 1 , 5 6. According to the technical solution of the present invention, the central axial powder feeding plasma spray gun includes: gland 1, anode nozzle 2, sealing ring 3, front gun body 4, sealing ring 5, sealing ring 6, insulator 7, cooling water pipe 8, rear Gun body 9, sealing ring compression nut 10, adjustment nut 11, elastic collet 12, compression nut 13, lock nut 14, powder feeding pipe joint 15, nut 16, cathode rod 17, cathode water and electricity connector 18, inlet Gas pipe connector 19, outer tungsten tube 20, inner tube 21, anode water and electricity connector 22.

[0046] The front gun body, the rear gun body, the insulator and the sealing ring are mechanically connected; the sealing ring 3 and the anode nozzle 2 are sequentially installed through the gland 1 at one end of the front gun body 4 by mechanical means.

[0047]One end of the cathode rod 17 close to the anode nozzle 2 is concentrically arranged with an inner tube 21 and an outer ...

Embodiment 2

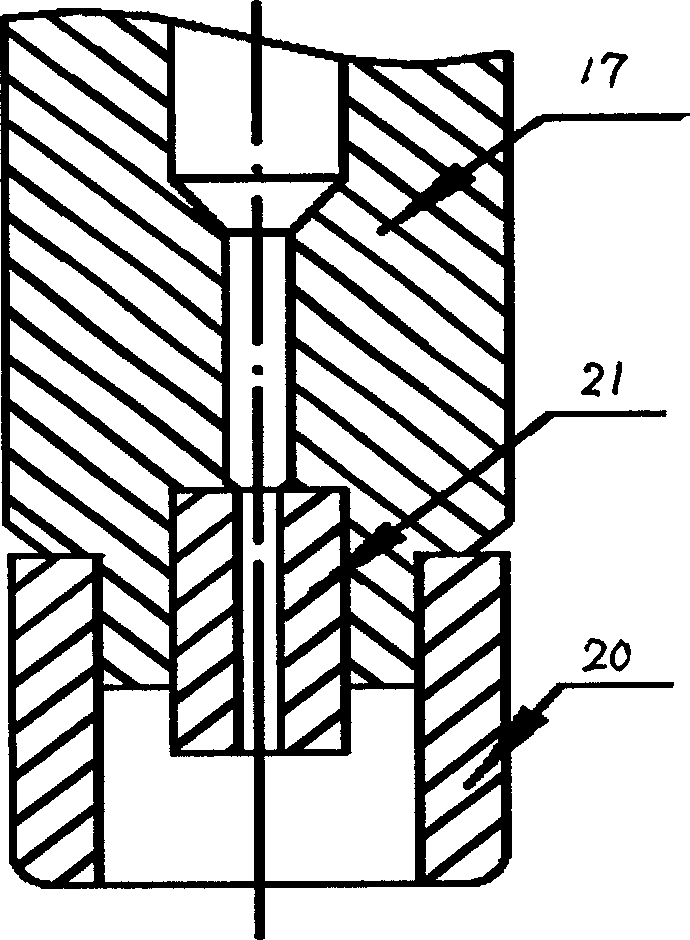

[0061] see figure 2 . According to the technical scheme of the present invention, such as figure 1 The hollow cathode structure of the plasma spraying gun shown includes a hollow support body of the cathode, and an inner tube with a through hole and an outer tungsten tube are also arranged at one end of the cathode hollow support body, and the inner tube is arranged on the hollow support body of the cathode. On the through hole, the outer tungsten tube is arranged on the outer diameter of one end of the cathode hollow support body, and there is a certain gap between the two tungsten tubes. Copper is used as the supporting body, the inner tube and the outer tungsten tube are connected at one end of the supporting body, and the material of the tungsten tube is cerium-tungsten alloy.

Embodiment 3

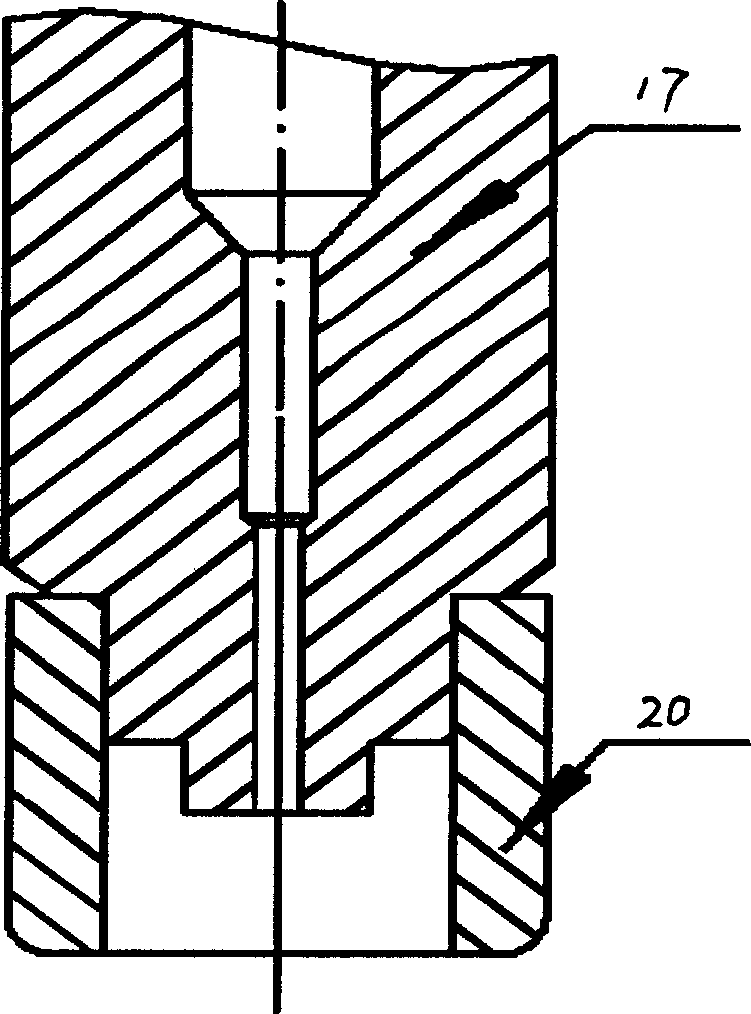

[0063] see image 3 . According to the technical scheme of the present invention, such as image 3 As shown, the inner tube and the cathode hollow support body are made of red copper at the same time, and the two are combined into one to form a whole. The solution of this kind of embodiment is relatively simple.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com