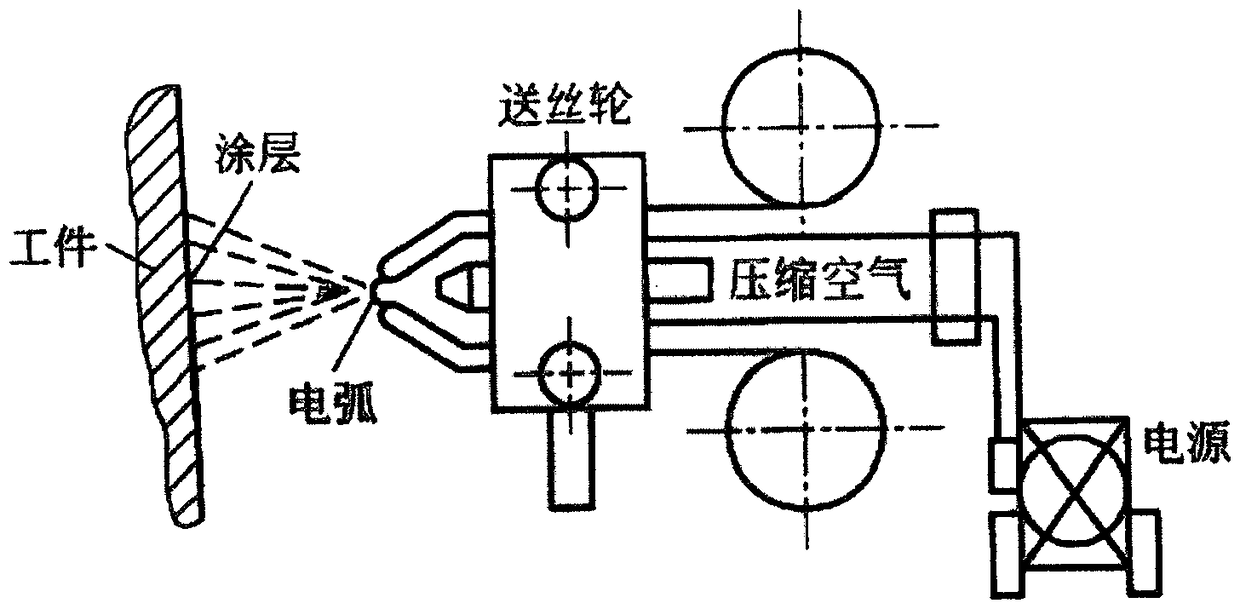

Electric arc spraying device

A technology of arc spraying and wire feeding device, which is applied in the direction of arc spraying, spray discharge device, etc., can solve the problems such as the inability to effectively atomize the metal wire and the inability to effectively adjust the spraying range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

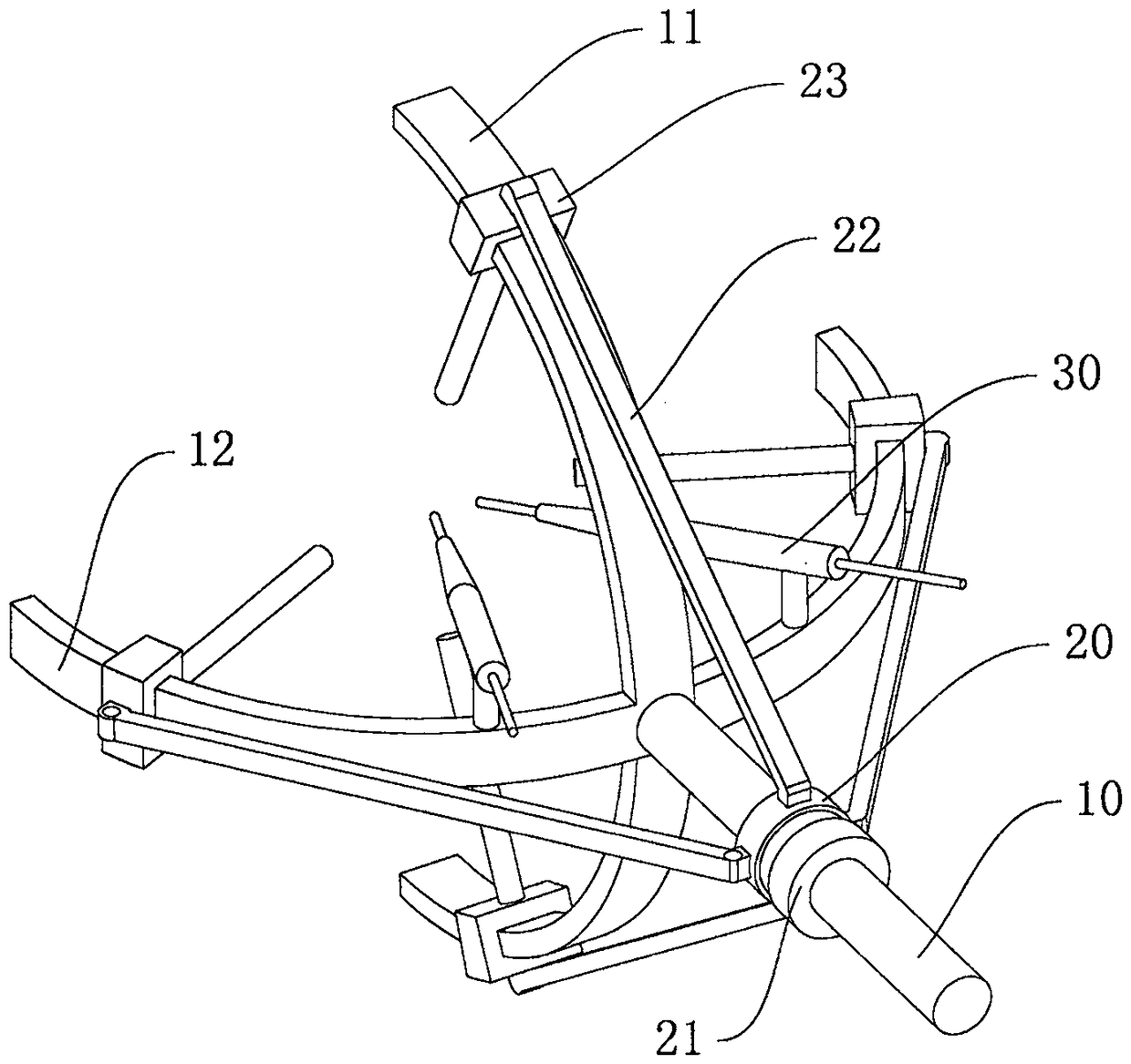

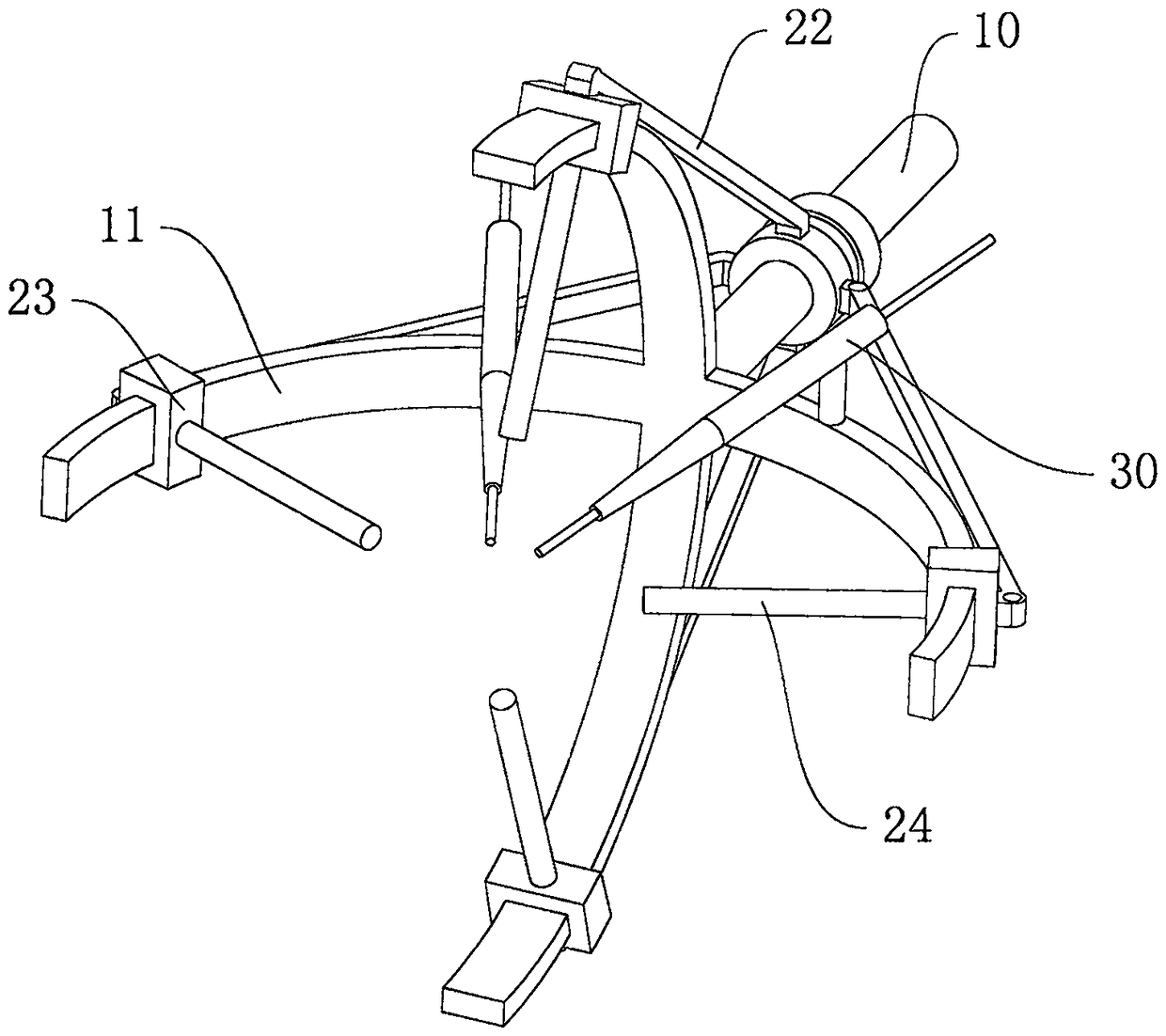

[0024] Such as Figure 2 to Figure 7 As shown, an arc spraying device provided by an embodiment of the present invention includes a wire feeding device and a gas source, and also includes:

[0025] Guide frame, it comprises first arc slide bar 11, second arc slide bar 12 and supporting screw 10, and the radius of described first arc slide bar 11 and described second arc slide bar 12 is identical and two The midpoints of the latter are intersected, the first arc-shaped slide bar 11 and the second arc-shaped slide bar 12 are on a hemispherical surface as a whole, and one end of the supporting screw 10 is fixedly connected to the intersection point;

[0026] The adjustment device comprises a connecting ring 20, a screw sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com