Inverter type electric arc spraying power source based on phase-shifted full-bridge

An arc spraying, phase-shifting full-bridge technology, applied in arc spraying, high-efficiency power electronic conversion, electrical components, etc., can solve the problems of inability to accurately control the output voltage, no feedback control, heavy weight, etc., to reduce switching losses, reduce The effect of heat dissipation and high output waveform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the present invention and do not limit the scope of the present invention.

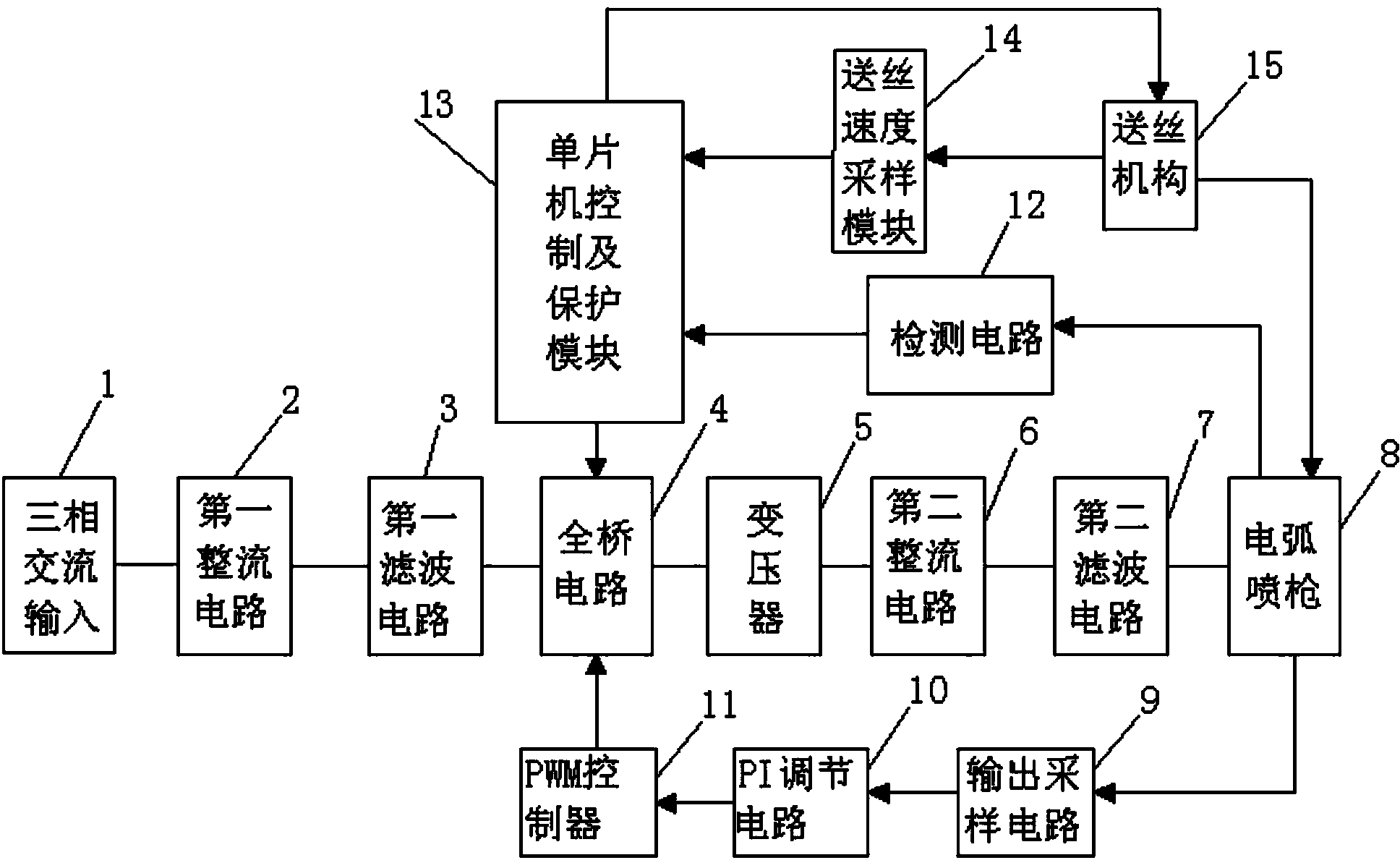

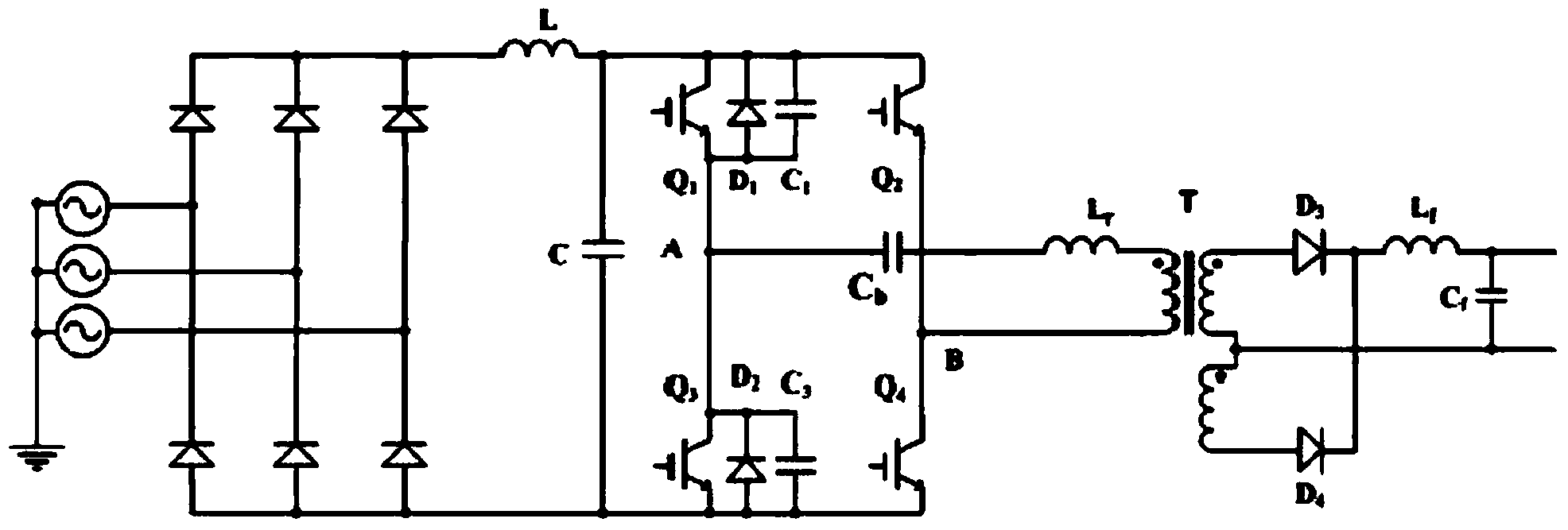

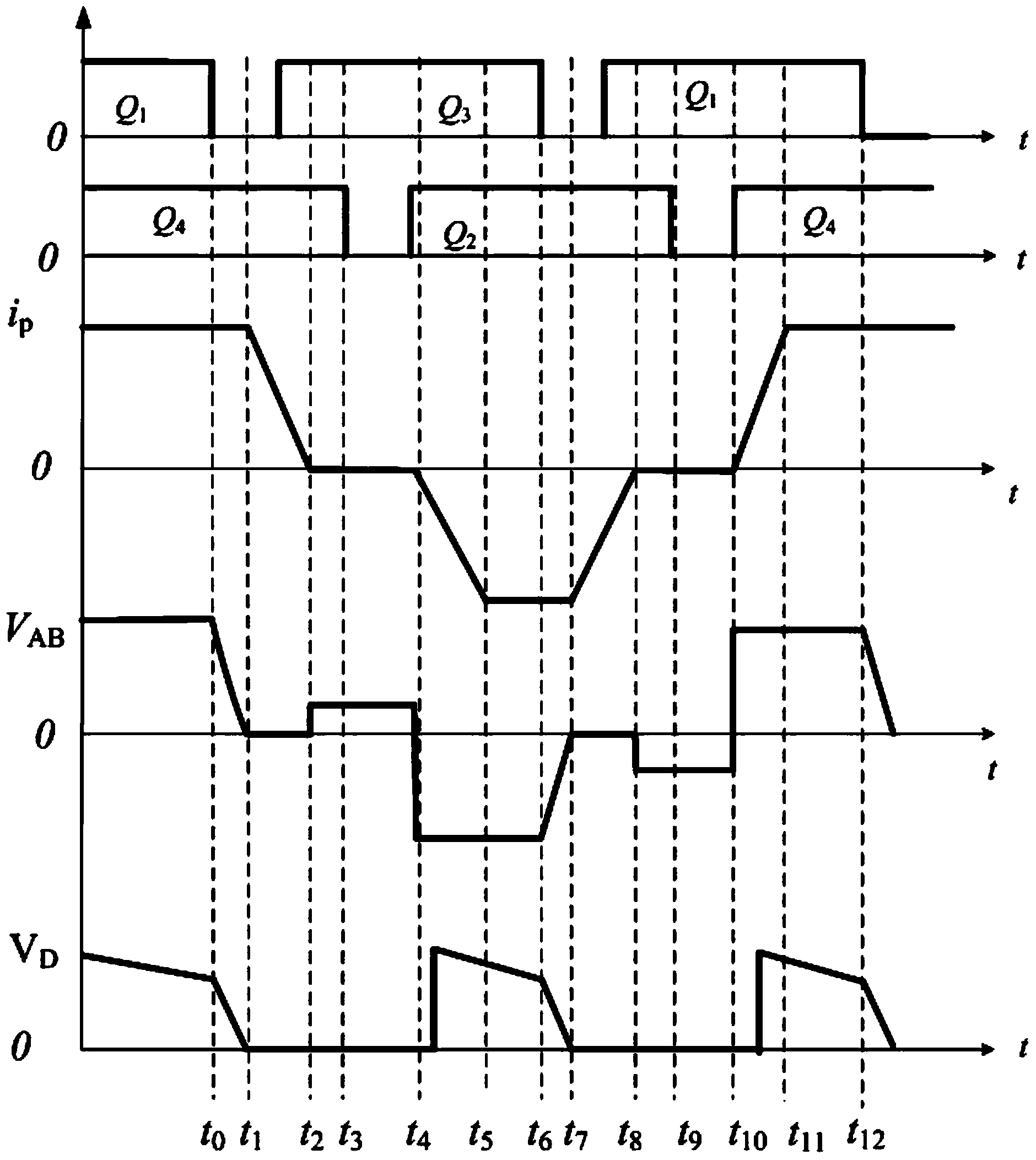

[0036] The existing arc spraying power supply mostly adopts the topology of power frequency transformer step-down, rectification and output constant voltage direct current, and the volume and weight of the magnetic components in the spraying power supply are large. Other inverter arc spraying power supplies mostly use hard switching technology, which has large switching loss and low efficiency. The inverter arc spraying power supply based on the phase-shifting full bridge of the present invention can accurately control the output voltage and current, adopts soft switching technology, reduces switching loss, improves the efficiency of the spraying power supply, and can implement real-time monitoring of the spraying power supply, automaticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com