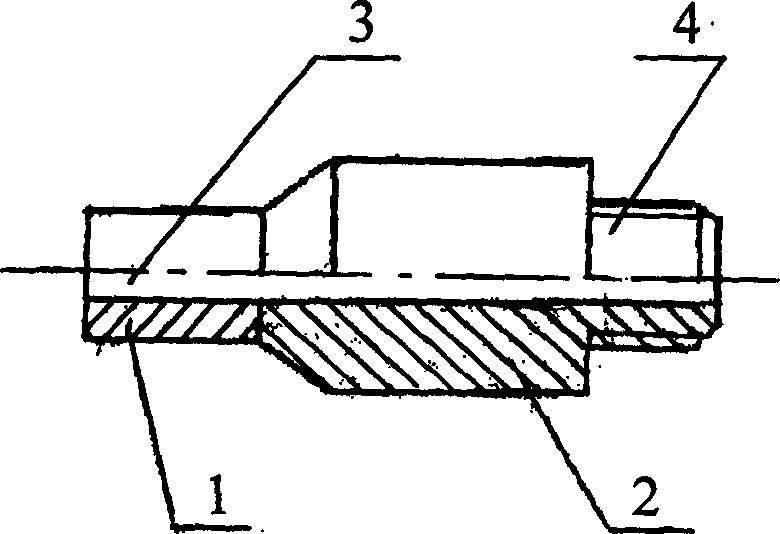

Electrode nozzle of electric arc spraying coater in supersonic speed and manufacturing method

A technology of supersonic arc and contact tip, which is applied in the direction of arc spraying, spraying device, spraying device, etc., and can solve problems affecting coating quality and production efficiency, contact resistance increase, arc breaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

0.3

[0036] Mix the powders of 80-250 mesh cermet components fully and evenly, press the mold according to the size required by the cermet part of the contact tip, and then sinter in a vacuum furnace or a gas shielded furnace. The sintering temperature is 1300-1480°C. The sintering time is 1 to 2 hours; put the sintered cermet into another forming mold, melt the above-mentioned copper alloy components in an intermediate frequency furnace with nitrogen protection and stir evenly, and then pour into the mold where the cermet has been placed In the process, the mold pouring temperature is controlled between 1200-1300°C, and the mold is released after cooling, and the cermet part and the copper alloy part are firmly sintered together. The hardness of cermet reaches HRA88-93, the conductivity of copper alloy is 85-90% IACS (the conductivity of red copper is 89-94% IACS), and the hardness is HRB75-82 (the hardness of red copper is HRB45-52).

[0037] The service life of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com