Fistular cathodic axial powder feeding plasma painting gun

A plasma and spray gun technology, applied in arc spraying, liquid spraying device, spraying device and other directions, can solve the problems of difficult processing, low energy utilization rate and high cost, and achieve high energy utilization rate, simple structure and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

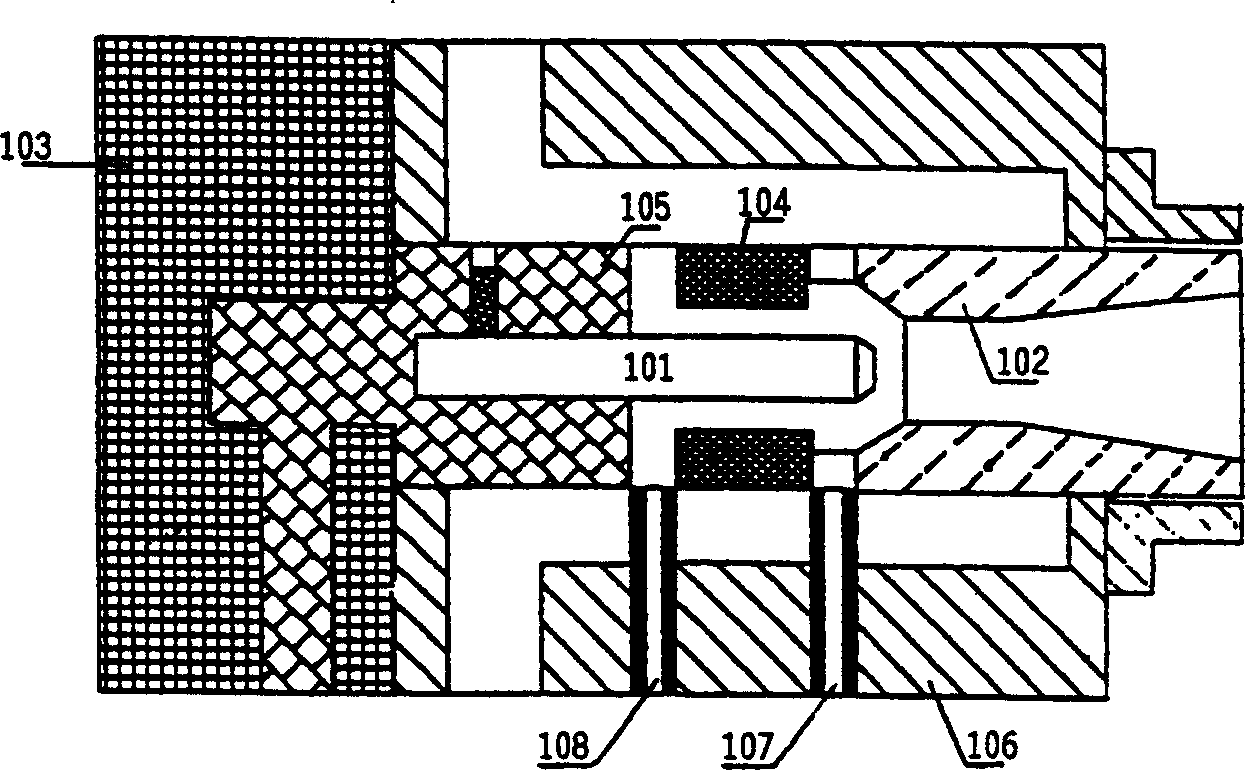

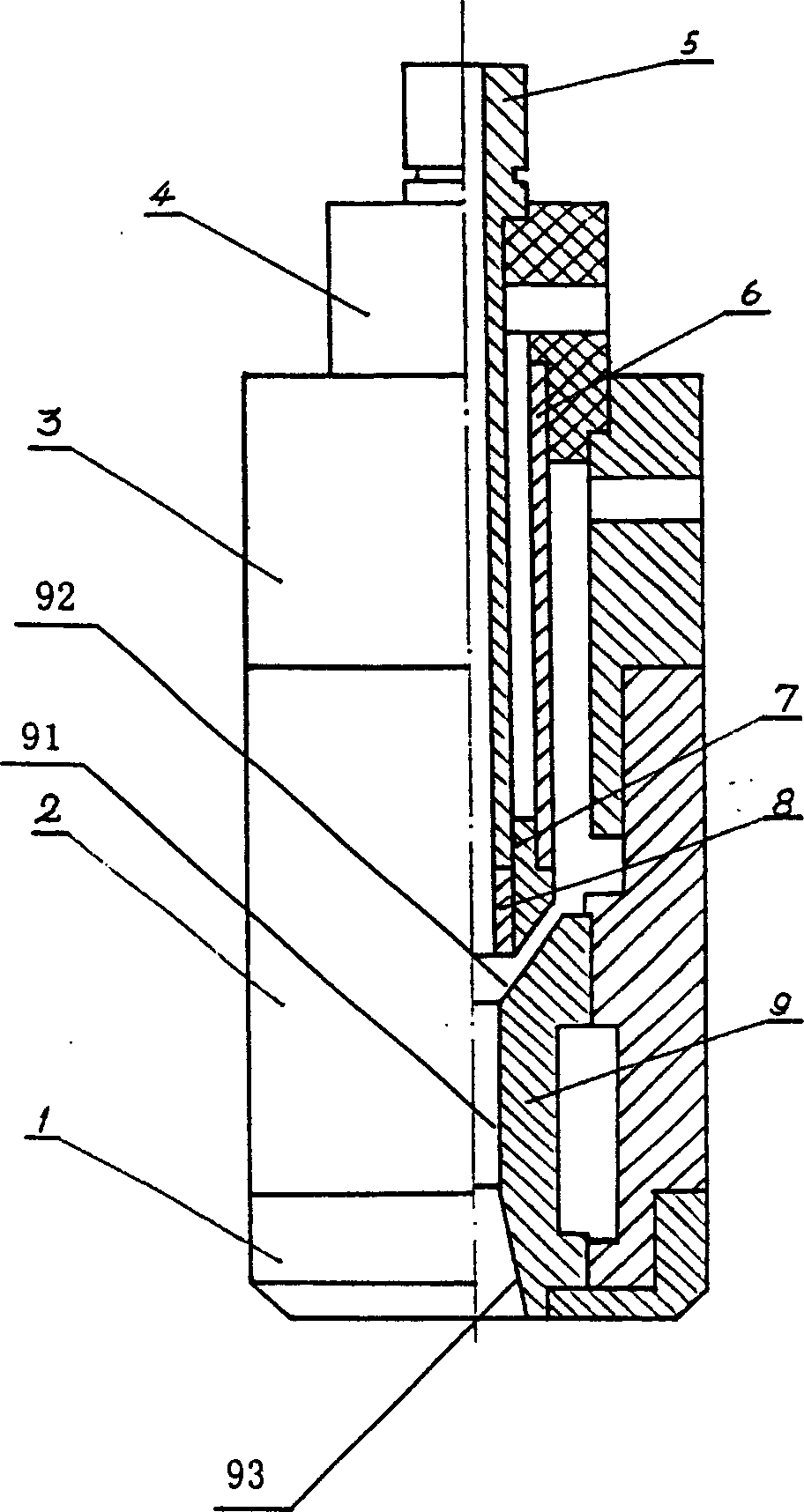

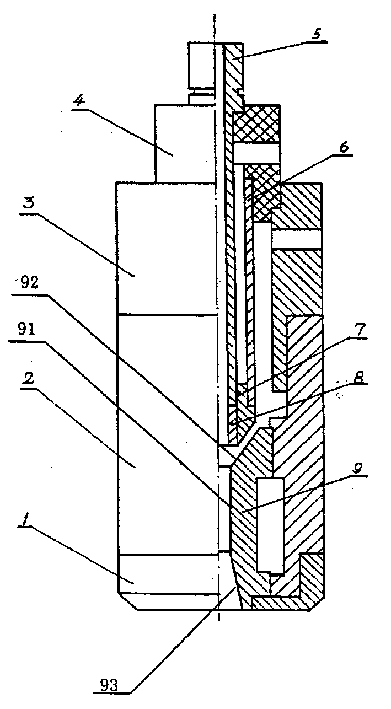

[0020] figure 2 Represents the structure of the axial powder feeding plasma spray gun of the embodiment of the present invention, which includes a compression nut 1, an anode body 2, an insulating sleeve 3, a cathode sleeve 4, a cathode powder feeding rod 5, a water guide sleeve 6, and a cathode seat 7 , cathode 8 and anode 9.

[0021] The cathode sleeve 4, the cathode powder feeding rod 5, the water guide sleeve 6, the cathode seat 7 and the cathode 8 constitute the cathode device, in which the cathode 8 and the cathode powder feeding rod 5 are both hollow tubular structures, and their axial directions are interpenetrating. The middle holes together constitute the powder feeding channel of the spray gun, and the diameter of the middle holes is selected as 3-6 mm. The cathode holder 7 is sleeved on the cathode for cooling the cathode 8, and the cathode and the cathode holder are replaceable. The cathode sleeve 4 is sleeved on the side of the cathode powder guide rod 5 close...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com