Multicomponent atmosphere controllable spraying method and apparatus

An atmospheric and multi-dimensional technology, applied in spray devices, devices for coating liquid on surfaces, arc spraying, etc., can solve the problems of large investment, impact on expected effects, and high production costs, and achieve simple device structure, high bonding strength, easy to use. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

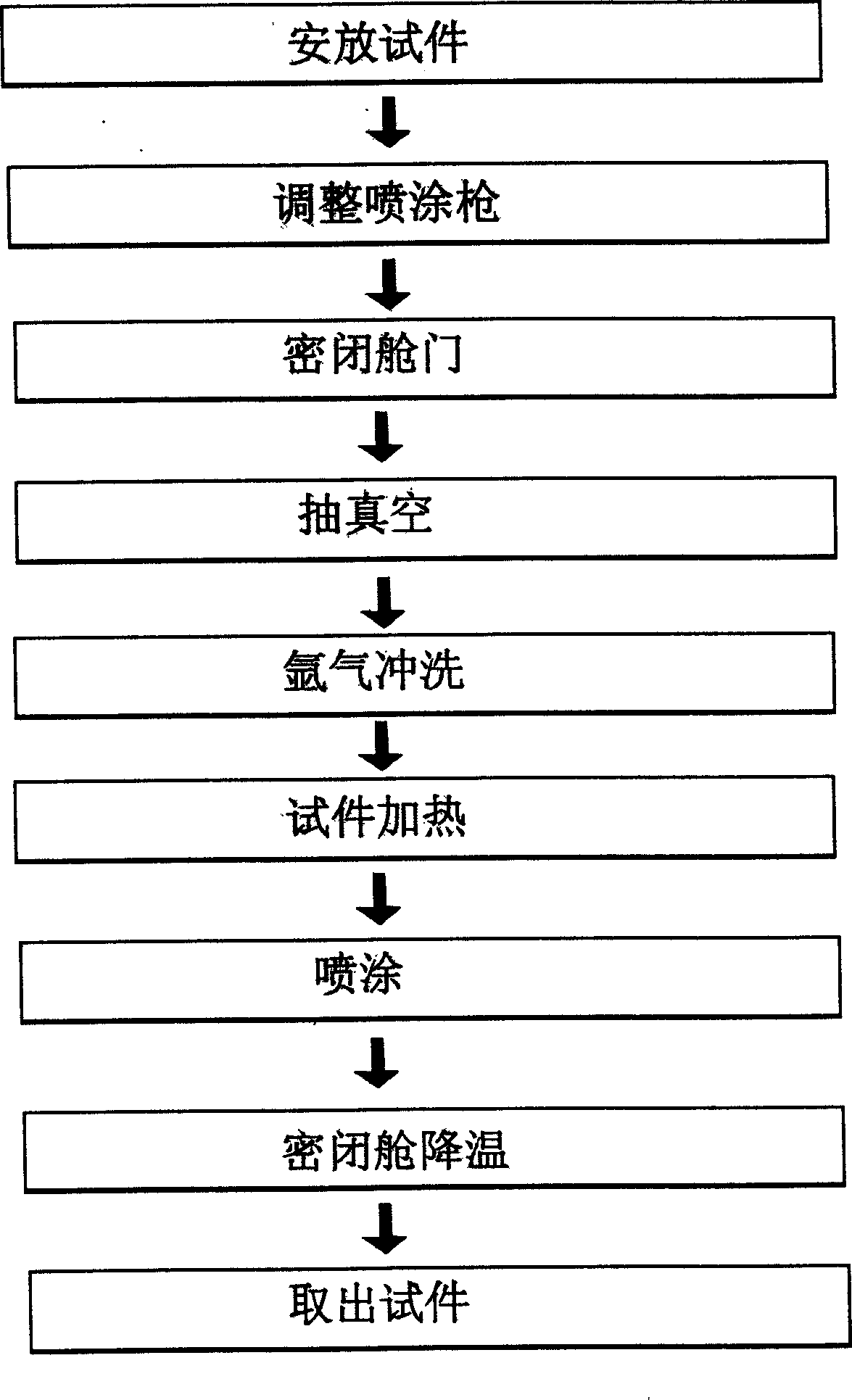

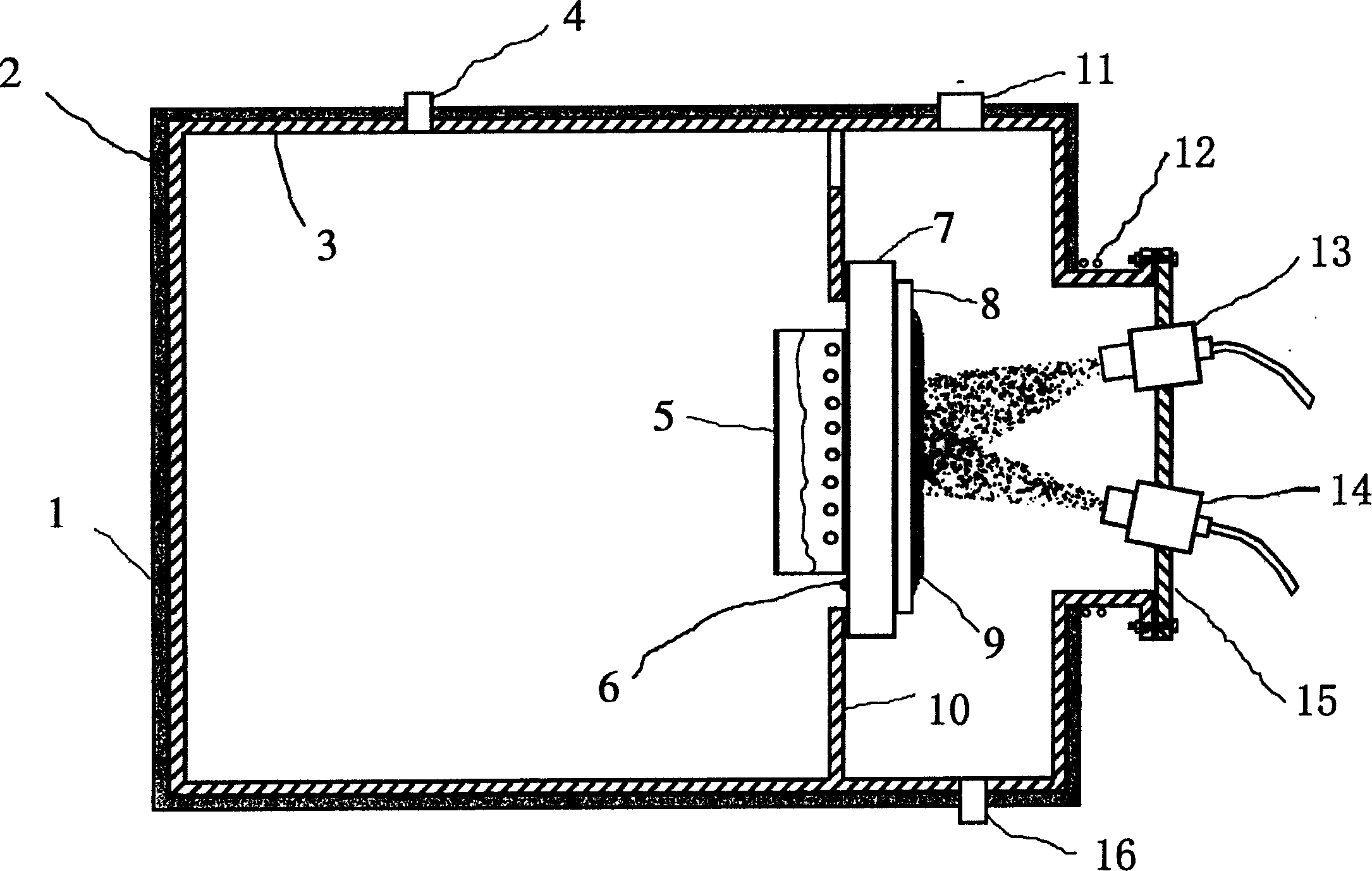

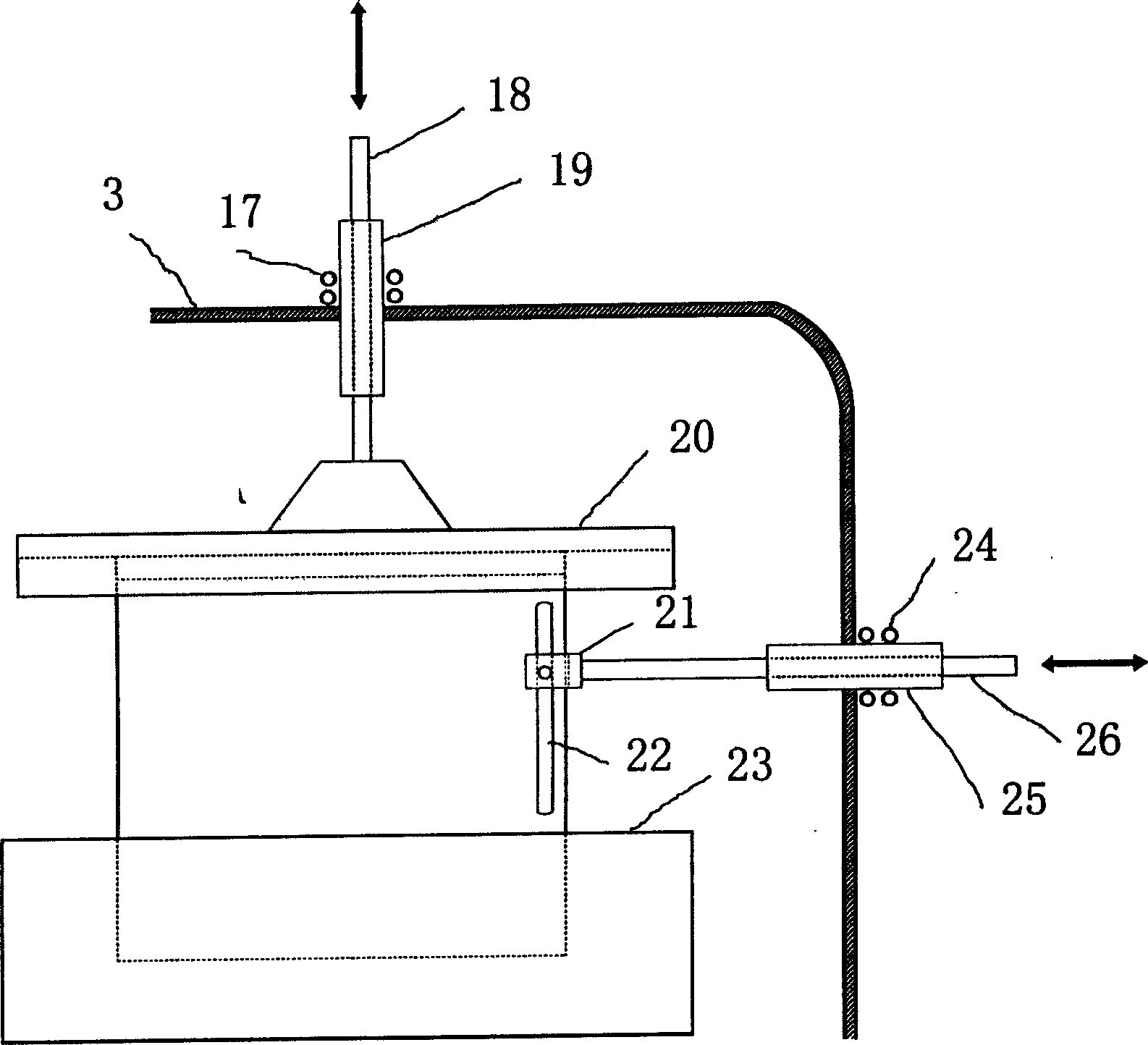

[0016] Prepare Fe with this method and device 3 Al compound coating, first need to prepare a piece for Fe 3 The substrate for Al compound coating deposition, the substrate may be carbon steel, or other metal materials with a melting point higher than 800°C. The surface of the substrate is pre-sandblasted to increase the deposition rate during coating deposition. The specific spraying process such as image 3 The process flow shown. After the base material sample is placed on the sample carrier, close the door of the airtight chamber and start to vacuum the airtight chamber. The vacuum in the airtight cabin reaches 6×10 -4 After hpa, further dilute the air components in the airtight cabin by flushing with argon. The method of argon flushing is: fill with argon, and then vacuumize. Under normal circumstances, repeated argon flushing twice can meet the requirements.

[0017] O in an airtight compartment 2 and N 2 After the content reaches the requirement, the heating pro...

example 2

[0025] Preparation of TiAl / Al by this method and device 2 o 3 The first few steps of the process of the composite material layer are the same as the above-mentioned application example 1 method, the difference is mainly the spraying material and spraying method used. There are two options for this process: option one is to use Al wire, Ti wire and Al wire 2 o 3 Ceramic powder is used as a spraying material, and arc spraying and plasma spraying are applied at the same time. Among them, the Al wire and the Ti wire are sprayed by electric arc, and the Al wire and the Ti wire are each an electrode, and the wire feeding speed of each wire is adjusted respectively, so that the content of Al and Ti in the formed coating has a promising ratio. While arc spraying Al and Ti, plasma spraying Al 2 o 3 Ceramic powder, so that the spray beams of the two spray guns are deposited on the same area to form Al, Ti and Al 2 o 3 A mechanical mixture coating of the three. Another solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com