Manufacture method of intelligence integral dies of arc spraying and brush plating

An arc spraying and mold manufacturing technology, applied in arc spraying, coating, spraying device and other directions, can solve the problems of low coating hardness and low deposition speed, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor according to the technical solution of the present invention.

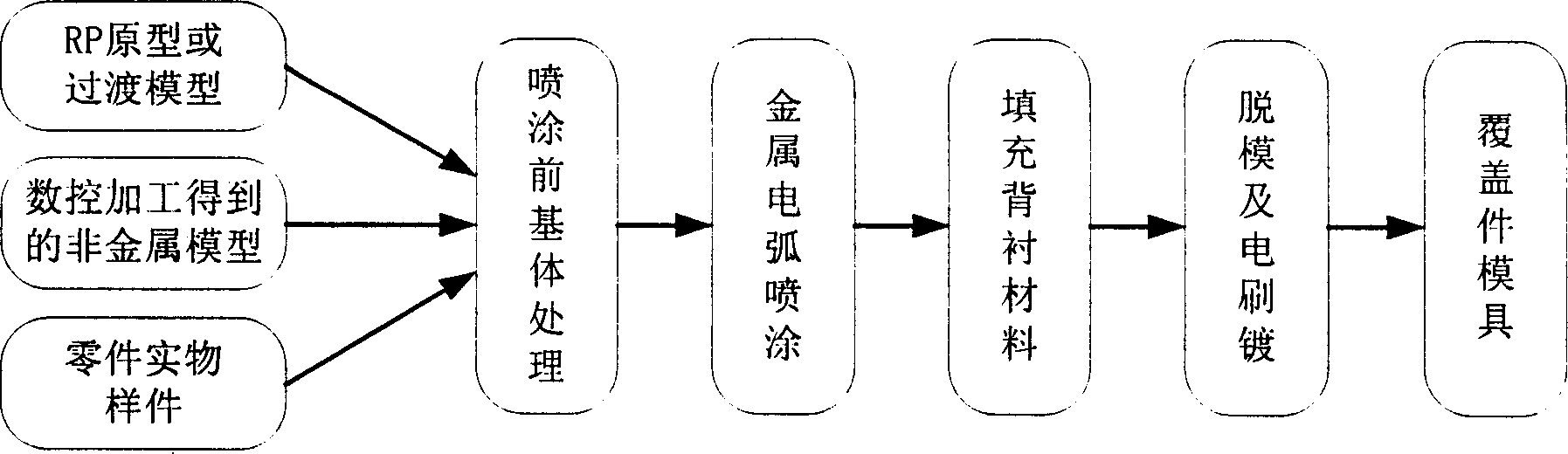

[0036] 1) The technical approach of mold manufacturing

[0037] see figure 1 , the technical approach of utilizing the present invention to carry out mold manufacturing is: 1. the non-metallic model or part sample obtained by RP prototype or transition model or numerical control processing is subjected to substrate treatment before spraying; 2. the above-mentioned model or sample after substrate treatment Parts are metal arc sprayed; ③ filling backing material; ④ stripping and brush treatment; ⑤ get half metal mold.

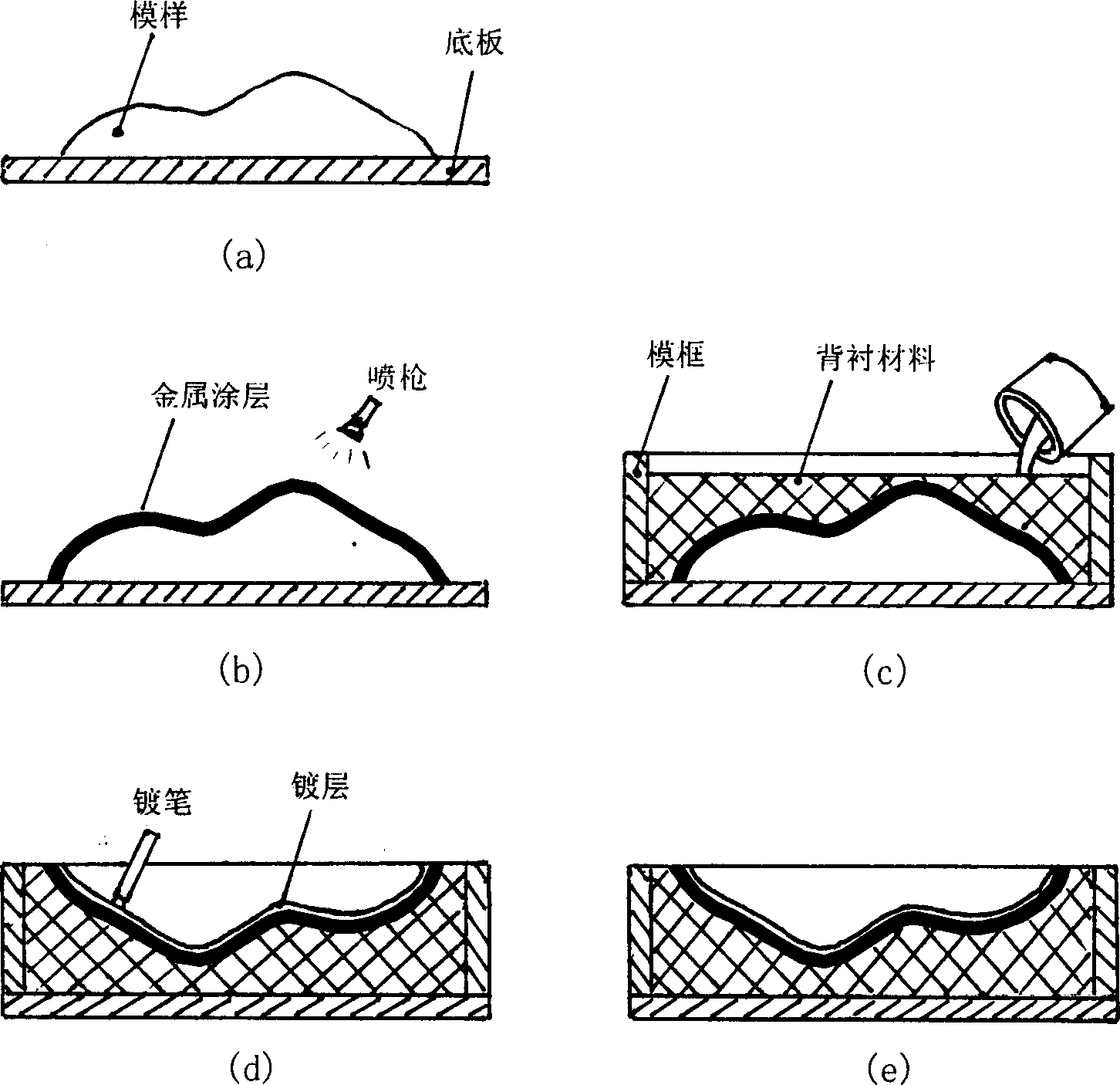

[0038] 2) Arc spraying and brush plating process route

[0039] see figure 2 .

[0040] ①Surface polishing

[0041] First apply a layer of release agent, then apply a layer of release agent evenly, and let it stand for 30 minutes.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com