Method for coating metal on the surface of integrated circuit structure

A technology of integrated circuits and structural surfaces, applied in the direction of circuits, arc spraying, electrical components, etc., can solve a large number of expensive machines, costly, error-prone and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

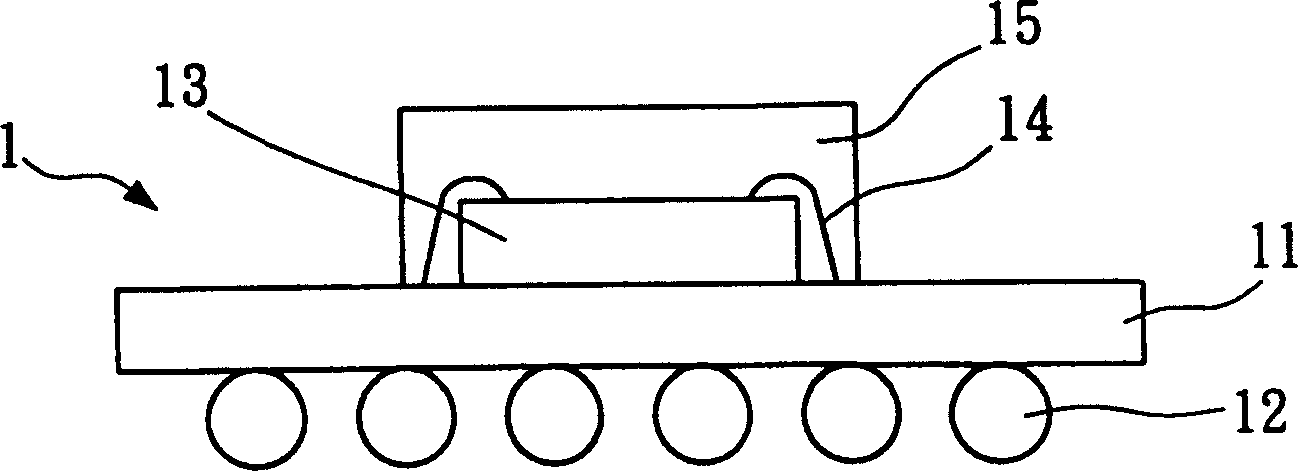

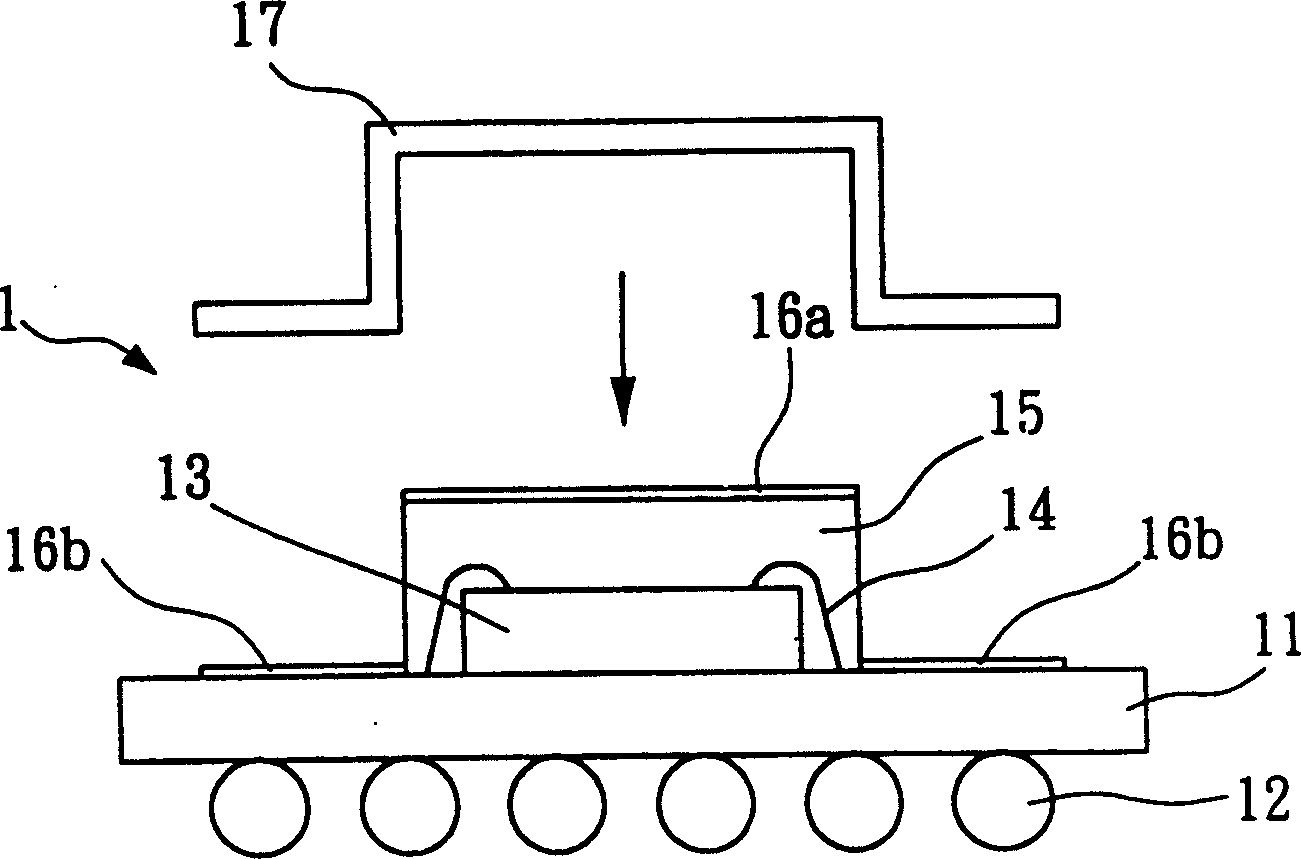

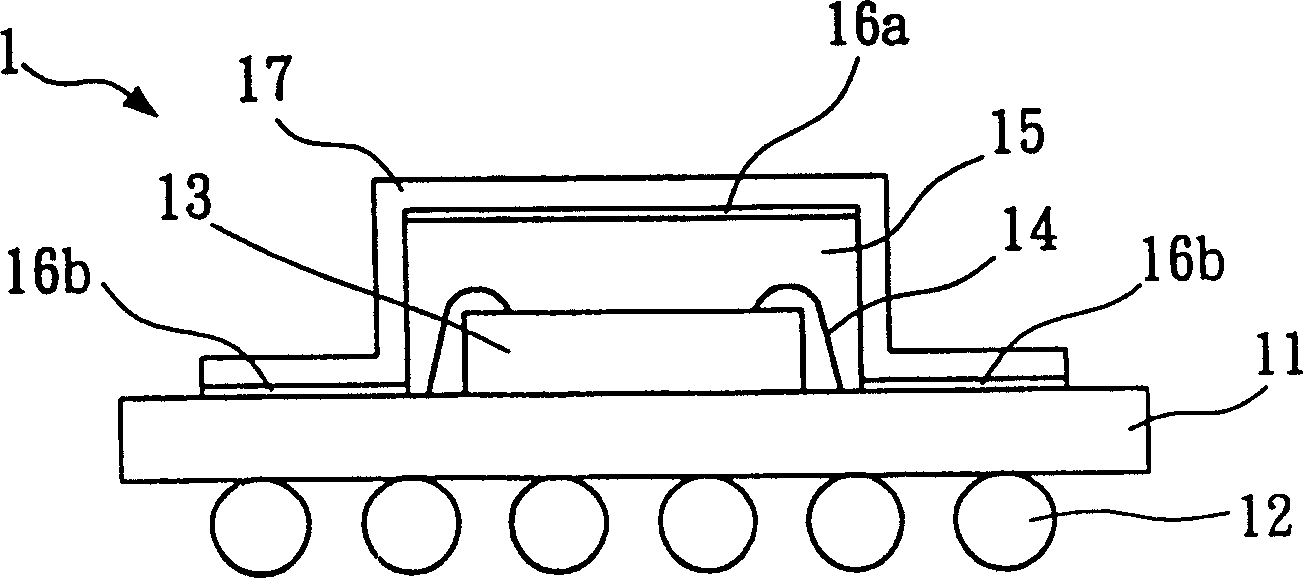

[0026] One of the main technical features of the present invention is that the metal coating layer is formed by metal spraying, which is suitable for integrated circuit structures of various sizes.

[0027] see Figure 3A to B are the first embodiment of the present invention. Firstly, an integrated circuit structure 3 is provided. The integrated circuit structure 3 is a packaging form in the general industry. It mainly includes a substrate 31 and a chip 33 disposed thereon. Generally, the industry can install more than one chip according to needs, and then Only one chip 33 is shown in the figure. The substrate 31 can be a ceramic substrate or a plastic substrate, the ceramic substrate uses ceramic material as the insulating layer, and the plastic substrate uses the plastic substrate as the insulating layer. The material thereof is bismaleimide (BMI), bismaleimide / triple nitrogen trap composite resin. Bismaleimide triazine-based, BT), epoxy resin (epoxy) FR-4 or polyamide (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com