Anti-power-failure arc spraying gun

An arc spray gun, spray gun body technology, applied in arc spraying, electrode accessories, spray devices and other directions, can solve the problems of spray gun arc break, contact nozzle and conducting rod burning, etc., to prevent spray arc break, avoid arc break phenomenon, work Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

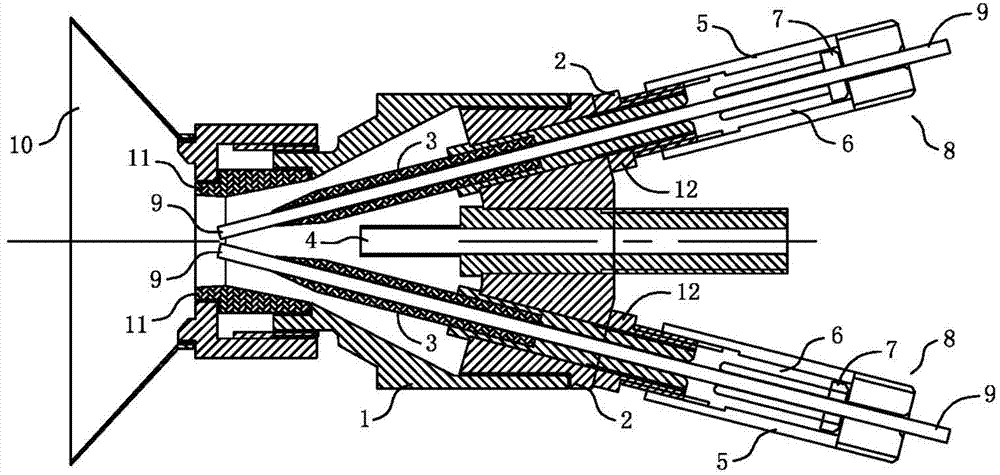

[0020] refer to figure 1 As shown, one embodiment of the present invention is a kind of anti-power arc spray gun, comprising a spray gun body 1 and a spray gun seat 2, wherein the spray gun body 1 is installed on the spray gun seat 2, and the inside of the spray gun seat 2 is provided with at least one The root guide tube 3 and the compressed air tube 4, and the opening of the front end of the spray gun body 1 corresponds to the outlet of the guide tube 3; more importantly, the position corresponding to the rear end of the aforementioned spray gun seat 2 and the entrance of the guide tube 3 A housing 5 is also fixed on the top, the other end of the housing 5 is connected to the connection plate 6, and the electrode bundle 7 is installed on the connection plate 6, and the electrode bundle 7 corresponds to the entrance of the guide wire tube 3. The electrode bundle 7 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com