Wiredrawing type high-speed electric arc spraying gun

An arc spraying and wire drawing technology, applied in arc spraying and other directions, can solve the problems of spraying jet divergence, aggravated wear of wire feeding parts, and low particle speed, and achieve spraying jet concentration, high-speed uniform atomization, and atomized particle concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

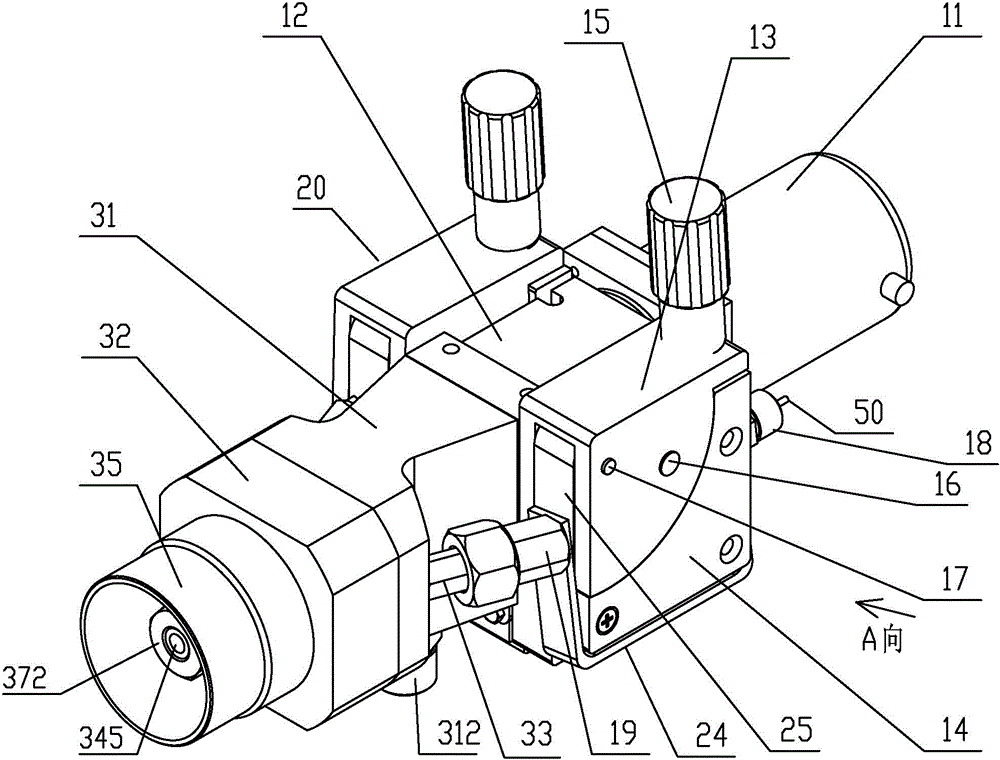

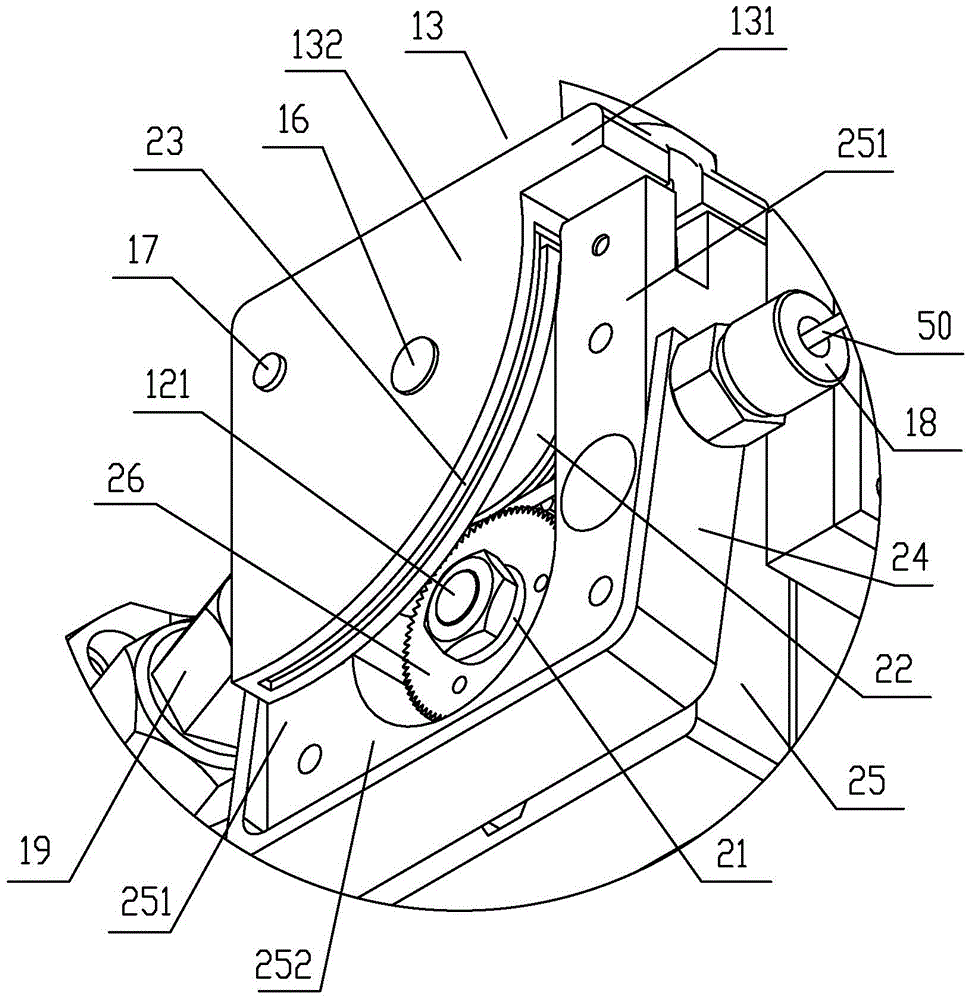

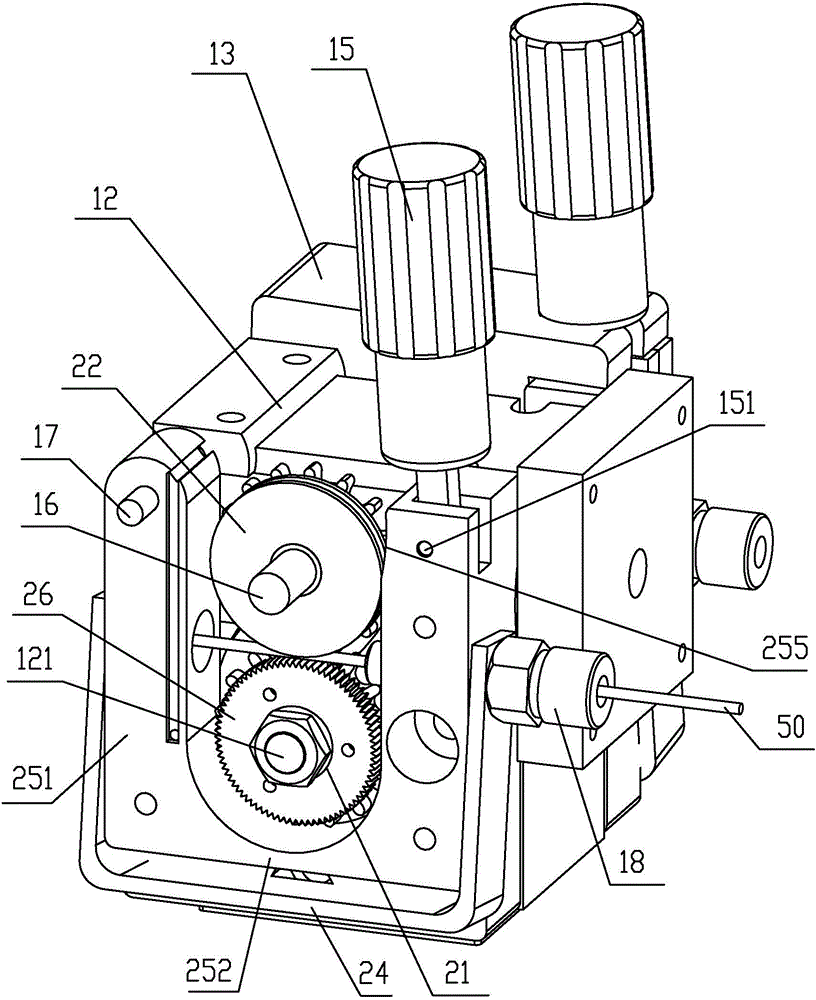

[0025] like Figure 1 to Figure 4 As shown, the wire-drawing high-speed arc spraying gun of the present invention includes a wire-feeding motor 11, a deceleration mechanism 12, a wire-feeding mechanism 20 and a spray gun head 30. 12 at both ends of the output shaft 121 (the output shaft 121 of the reduction mechanism 12 is a double output shaft, and this double output shaft has two output ends, and these two output ends are respectively located on both sides of the reduction mechanism 12) Each is connected to a wire feeding mechanism 20 , that is, the two wire feeding mechanisms 20 are respectively located on both sides of the reduction mechanism 12 and are symmetrically distributed. Specifically, the power of the wire-feeding motor 11 is output to the reduction mechanism 12 through its output shaft, and the reduction mechanism 12 outputs the power to the wire-feeding mechanism 20 through its output shaft 121 after the power is regulated by reducing the speed and increasing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com