Process and device for preparing thin strips by roller method sputtering forming

A roller method and thin strip technology, applied in the direction of metal rolling, etc., can solve the problems of atomization nozzle inner chamber degeneration, uneven thickness, difficulty in meeting the requirements of nozzles, etc., and achieve the effect of overcoming inhomogeneity and improving atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

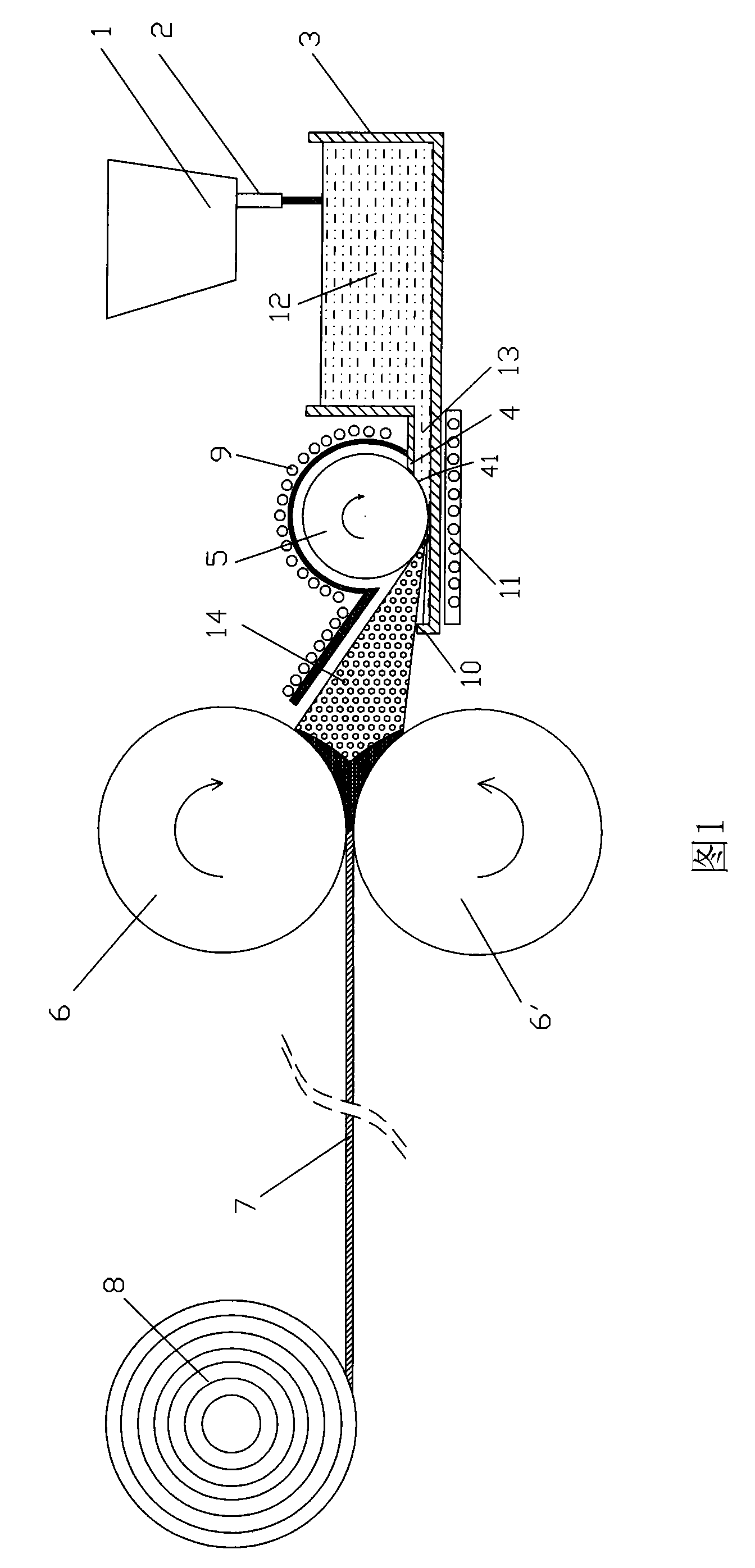

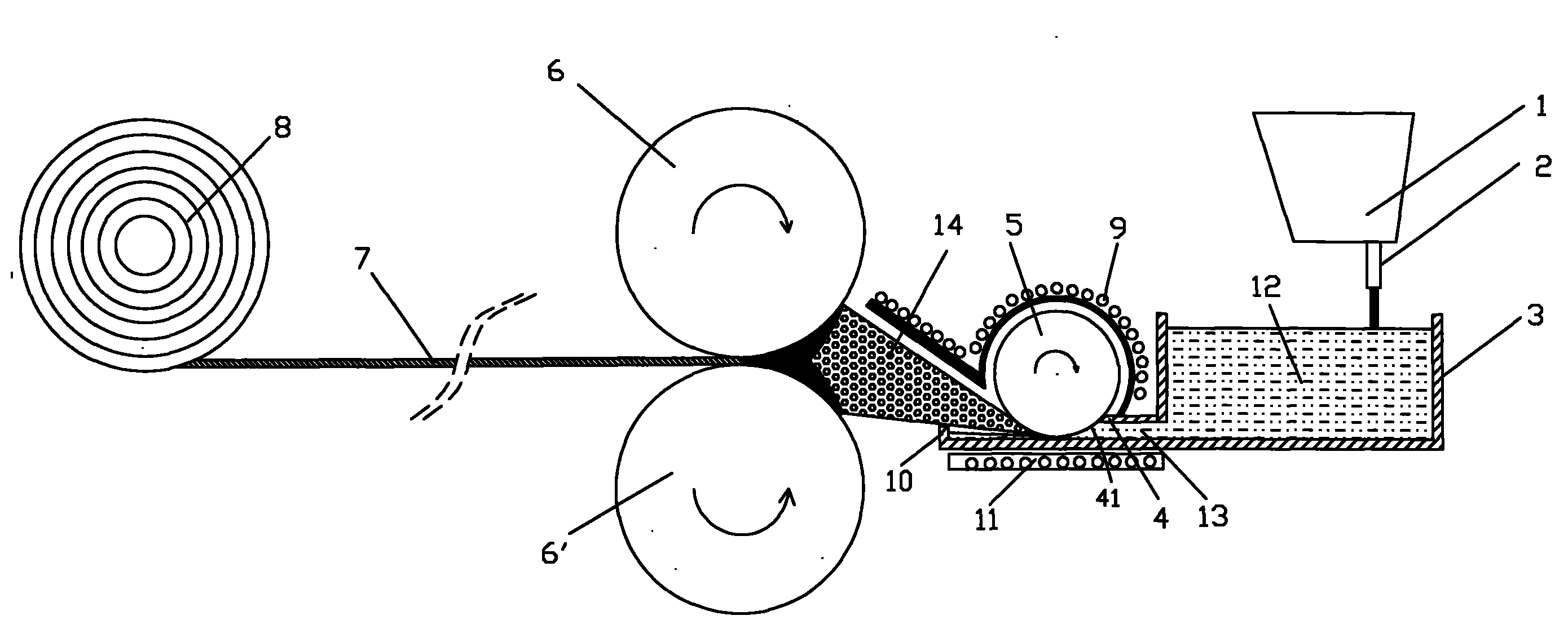

Embodiment 1

[0045] Pour the molten metal into the ladle, the superheat of the molten metal is kept at about 20°C, the ladle transports the molten steel to the ladle through the nozzle, the liquid level of the ladle is kept at 200mm, and the height of the liquid film prefabricated plate is 20mm. Connected with the drum, the diameter of the drum is 300mm, and there is a heater inside the drum, so that the temperature of the drum is kept lower than the temperature of the molten metal by about 20°C. The gap between the bottom of the drum and the bottom of the prefabricated plate is 5mm wide, and the rotating speed of the drum is 200r / min. The height of the baffle is 30mm, the distance between the cylinder and the crystallization roller is 350mm, the interval between the crystallization rollers is 2mm, the rotating speed of the crystallization roller is 100r / min, the pulling speed of the thin strip is 60m / min, and the temperature of the heater is controlled at It is not advisable to solidify th...

Embodiment 2

[0047] Pour the molten metal into the ladle, the superheat of the molten metal is kept at about 22°C, the ladle transports the molten steel to the ladle through the nozzle, the liquid level of the ladle is kept at 230mm, and the height of the liquid film prefabricated plate is 15mm. Connected to the drum, the diameter of the drum is 260mm, and there is a heater inside the drum to keep the temperature of the drum lower than the molten metal at about 18°C. The gap between the bottom of the drum and the bottom of the prefabricated plate is 6mm wide, and the rotation speed of the drum is 230r / min. The height of the baffle is 25mm, the distance between the drum and the crystallization roller is 380mm, the interval between the crystallization rollers is 2.5mm, the rotation speed of the crystallization roller is 120r / min, the pulling speed of the thin strip is 80m / min, the temperature control of the heater It is preferable that the molten metal solidifies not between the prefabricated...

Embodiment 3

[0049] Pour the molten metal into the ladle, the superheat of the molten metal is kept at about 23°C, the ladle transports the molten steel to the ladle through the nozzle, the liquid level of the ladle is kept at 280mm, and the height of the liquid film prefabricated plate is 12mm. Connected to the drum, the diameter of the drum is 280mm, and there is a heater inside the drum to keep the temperature of the drum lower than the molten metal at about 22°C. The gap between the bottom of the drum and the bottom of the prefabricated plate is 4mm wide, and the rotating speed of the drum is 260r / min. The height of the baffle is 28mm, the distance between the cylinder and the crystallization roller is 400mm, the interval between the crystallization rollers is 4mm, the rotating speed of the crystallization roller is 130r / min, the pulling speed of the thin strip is 100m / min, and the temperature of the heater is controlled at It is not advisable to solidify the molten metal between the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com