Air filtering and purifying device for producing modified starch

An air filtration and purification device technology, which is applied in the direction of combined devices, climate change adaptation, and dispersed particle filtration, etc., which can solve the problems of poor dust removal effect and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

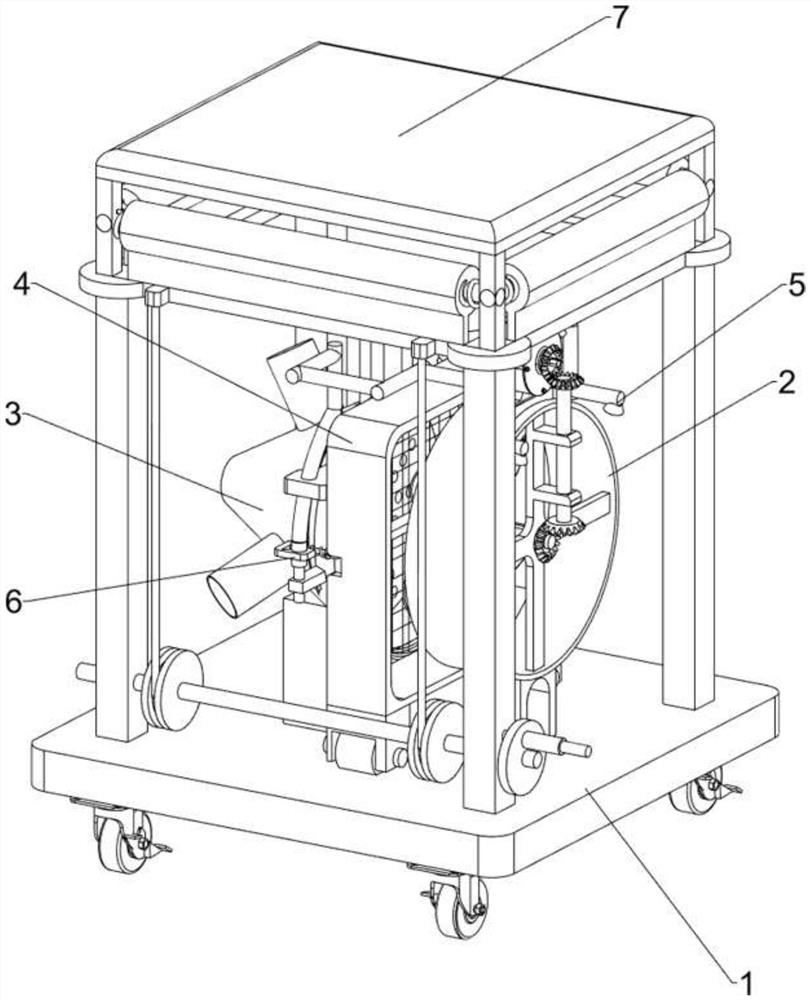

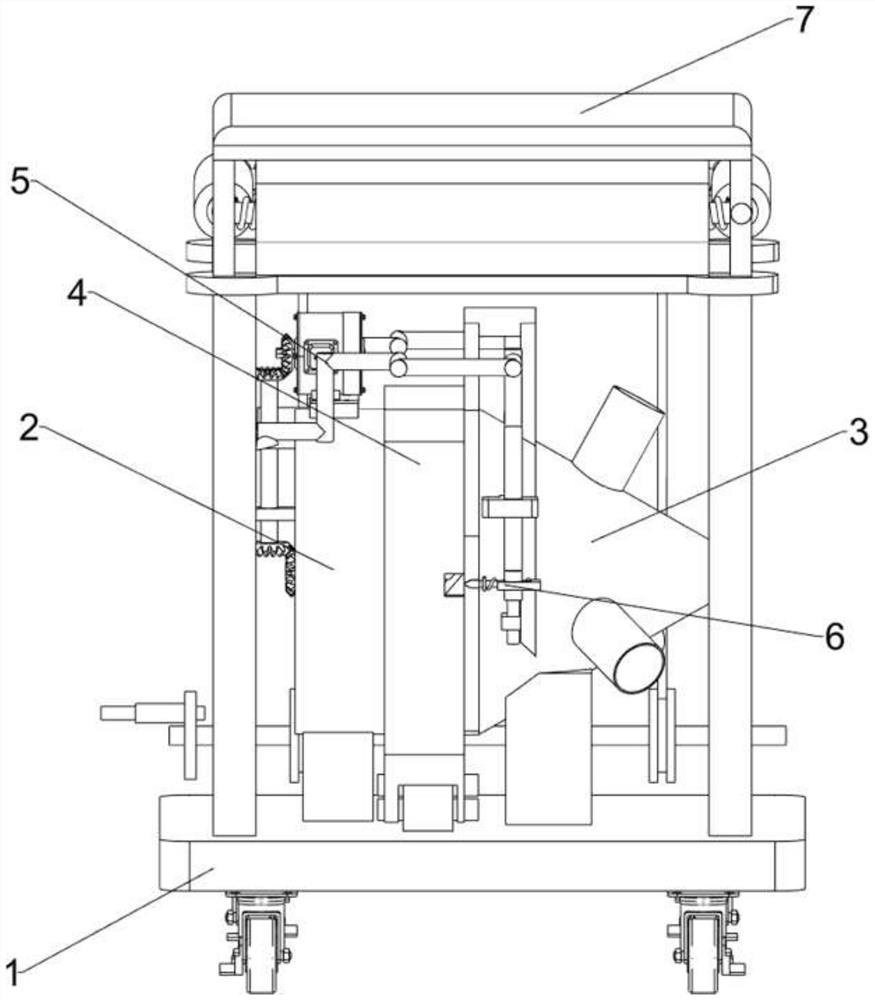

[0071] A modified starch production air filter purification device, such as figure 1 with figure 2As shown, it includes a bottom plate 1, a blower mechanism 2 and a filter mechanism 3, the bottom plate 1 is provided with a blower mechanism 2 on the right side, and the bottom plate 1 is provided with a filter mechanism 3 on the left side.

[0072] In the process of producing modified starch, people need to use a filter and purification device in order to avoid the explosion of dust when it encounters an open flame. The blower mechanism 2 blows to the filter mechanism 3, and the filter mechanism 3 filters and absorbs the dust, and the blower mechanism 2 is closed when the production of starch is stopped.

Embodiment 2

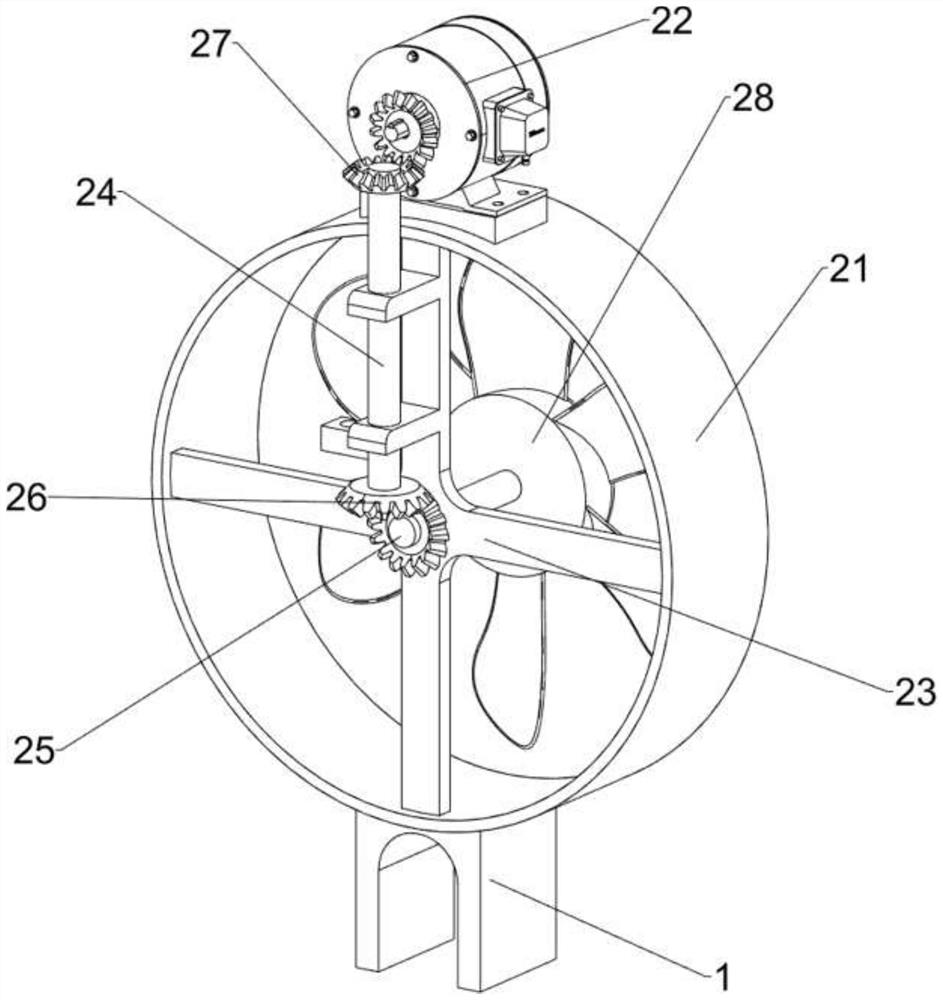

[0074] On the basis of Example 1, such as image 3 with Figure 4 As shown, the blower mechanism 2 includes a casing 21, a servo motor 22, a fixed frame 23, a first rotating shaft 24, a second rotating shaft 25, a first conical tooth set 26, a second conical tooth set 27 and a fan 28, and the bottom plate 1 The upper right side is provided with a housing 21, the top of the housing 21 is equipped with a servo motor 22, the inner wall of the housing 21 is provided with a fixed frame 23, the upper part of the fixed frame 23 is rotatably provided with a first rotating shaft 24, and the middle part of the fixed frame 23 is rotatably provided with a second rotating shaft 25. A first conical tooth set 26 is provided between the lower part of the first rotating shaft 24 and the right part of the second rotating shaft 25, and a second conical tooth set 27 is provided between the upper part of the first rotating shaft 24 and the output shaft of the servo motor 22. A fan 28 is provided ...

Embodiment 3

[0079] On the basis of Example 2, such as Figure 5-8 Shown, also comprise clearing mechanism 4, and clearing mechanism 4 comprises retaining frame 41, connecting column 42, cut block 43 and roller 44, and the front and rear sides on bottom plate 1 are all rotatably provided with roller 44, between two rollers 44 A blocking frame 41 is connected, and two connecting columns 42 are arranged on the left side of the fan 28 , and a cutting block 43 is connected between the two connecting columns 42 .

[0080] The fan 28 rotates to drive the connecting column 42 to rotate, thereby driving the cutting block 43 to rotate. The cutting block 43 can promptly scrape off the impurities adsorbed on the filter grid 32, improve the utilization rate of the filter grid 32, and facilitate people to clean the filter screen later. For the cleaning of grid 32, in the process of blasting and blowing dust, due to the centrifugal effect, part of the dust is adsorbed on the inner wall of the retaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com