Induction charging and corona charging combined two-stage charging atomizing nozzle

A corona charging and atomizing nozzle technology, used in induction discharge spraying, arc spraying and other directions, can solve the problems of large diameter of the cone-shaped electrode, decreased electric field strength, unsatisfactory charging effect, etc., to achieve charging safety and Improved reliability, reduced charging voltage requirements, and the effect of avoiding inductive charging processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

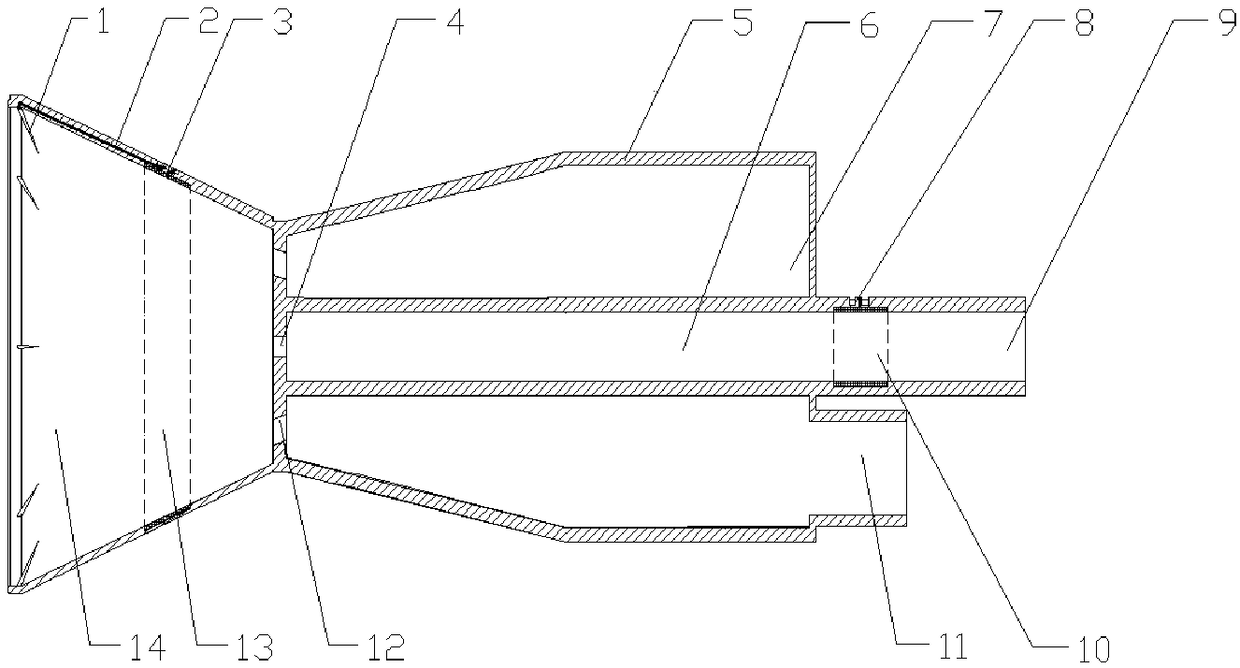

[0020] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

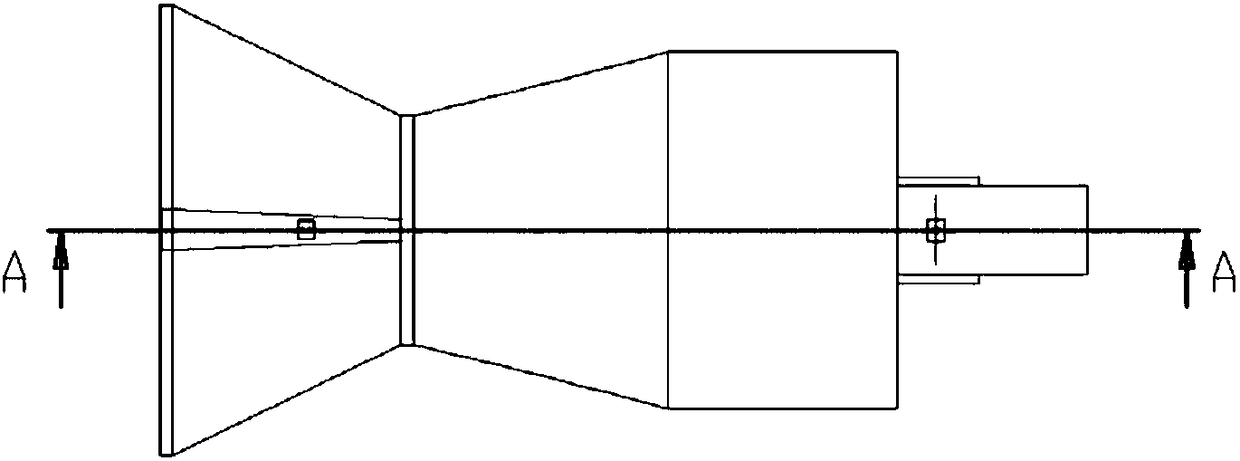

[0021] According to the present invention, a two-stage charged atomizing spray nozzle combined with induction charging and corona charging, its structure is as follows: Figure 1~4 As shown, the nozzle includes a liquid medicine nozzle 6 , an air flow nozzle 7 , and a tapered charging chamber 14 .

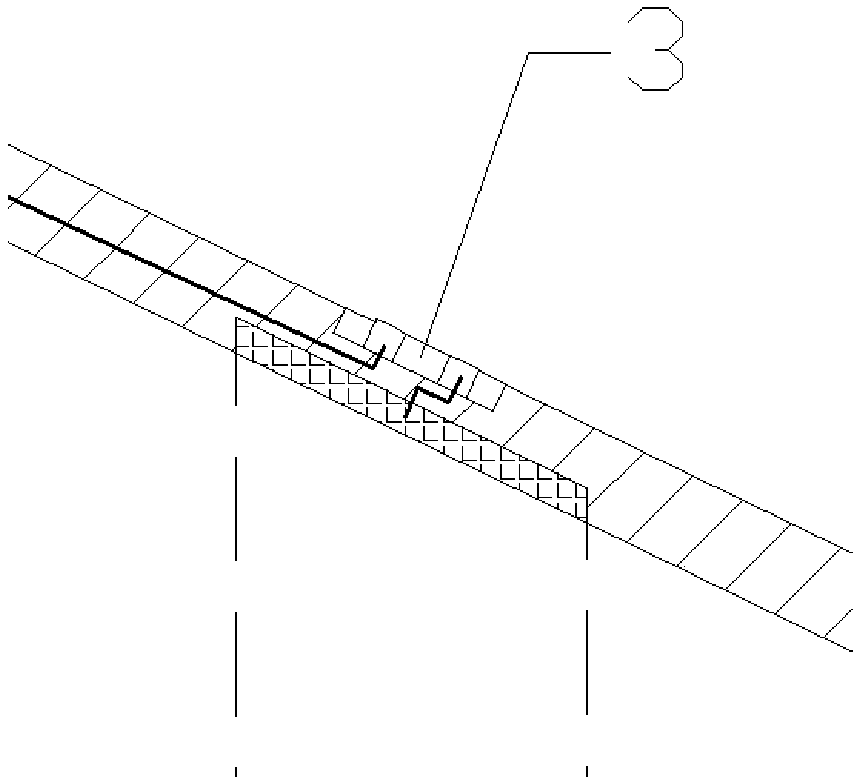

[0022] The liquid medicine nozzle 6 is a hollow cylindrical cavity, located on the central axis of the spray body 5, a ring-shaped liquid medicine electrode 10 is embedded in the inner wall of the middle part of the liquid medicine nozzle 5, and there is a quick-connect plug 3 on the outer wall of the corresponding nozzle, which is convenient for power supply; The rear part of the liquid spray pipe 5 is a liquid medicine inlet 9, and the front part is a conical nozzle 4, so that the liquid medicine forms droplets by pressure atomization.

[0023] The rear portion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com