Stainless steel anti-corrosion pipe used for oil gas field and manufacturing method thereof

A stainless steel and anti-corrosion pipe technology, applied in arc spraying and other directions, can solve the problems of short service life, poor anti-scaling effect, etc., achieve high mechanical strength, corrosion resistance, strong adhesion, and solve the effect of difficult thread anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

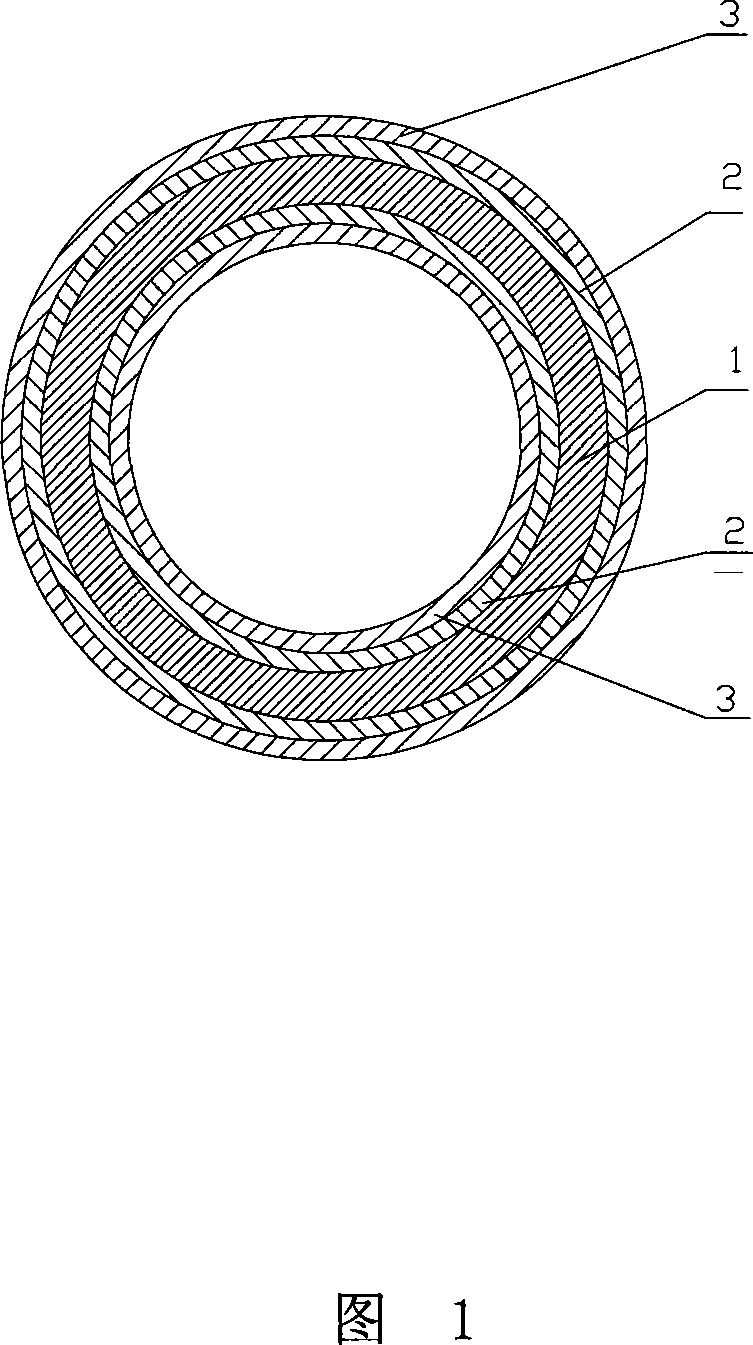

[0010] Below in conjunction with embodiment the present invention is further described: as shown in Figure 1: by the stainless steel anticorrosion oil pipe or sleeve pipe that the present invention makes by oil pipe, casing body (1), oil pipe, casing body (1) inner and outer wall plating It consists of an iron-aluminum multi-element alloy layer (2) and a pure alloy layer (3).

[0011] The prepared stainless steel anti-corrosion oil pipe or casing is processed into a 30cm short joint, and the mechanical performance test is carried out on a mechanical performance testing machine, including tensile strength, yield strength and elongation. And according to GB / T14976-1994 stainless steel seamless steel pipe standard for fluid transportation, comparative analysis is carried out. The experimental method and experimental conditions are based on the GB / T14976-1994 standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com