Anticorrosion pipe provided with alloy layers

A technology of alloy layer and anti-corrosion pipe, which is applied in pipeline anti-corrosion/rust protection, drill pipe, casing, etc. It can solve the problems of poor anti-scaling effect and short service life, and achieve strong adhesion, high mechanical strength and durability erosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

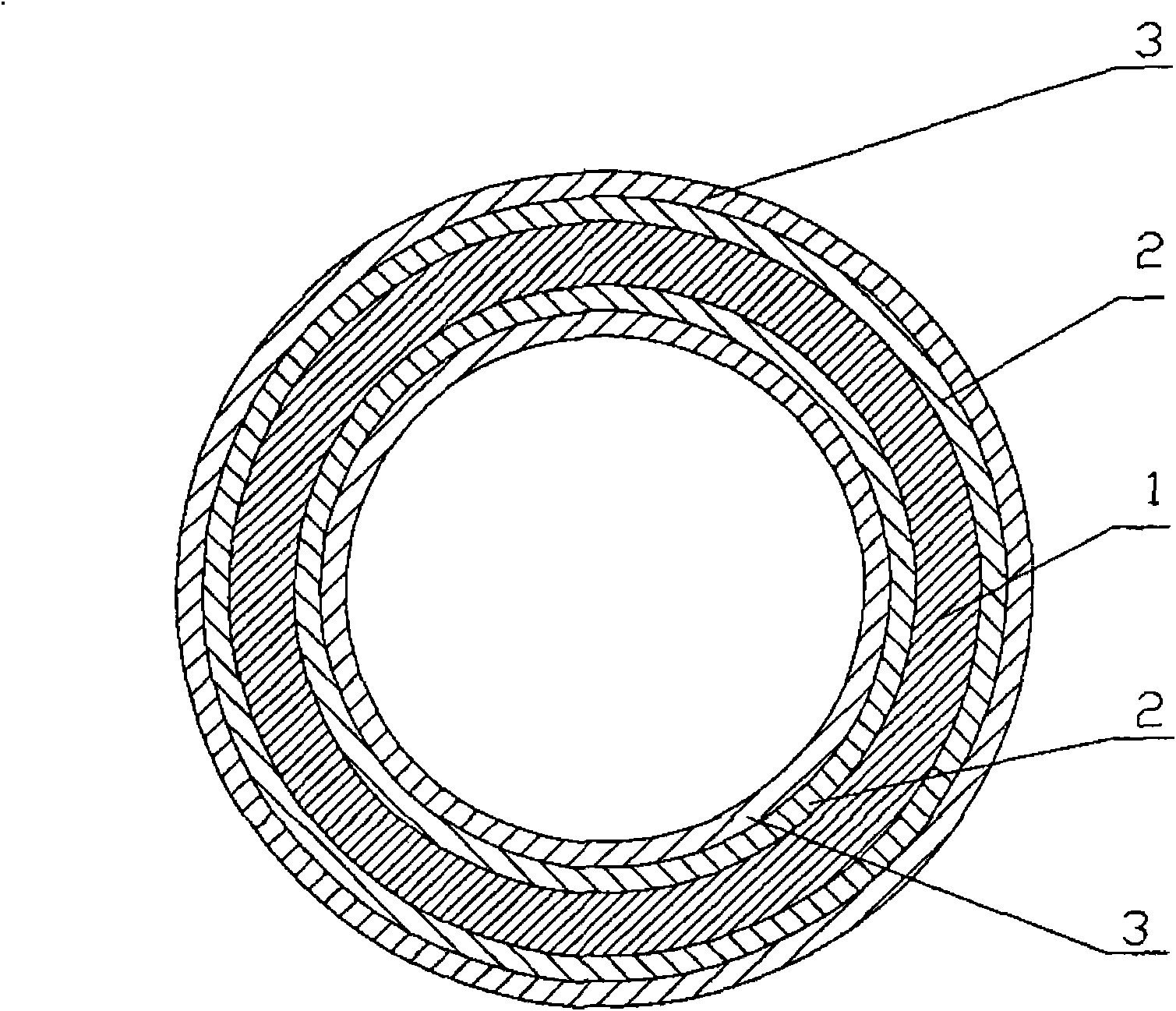

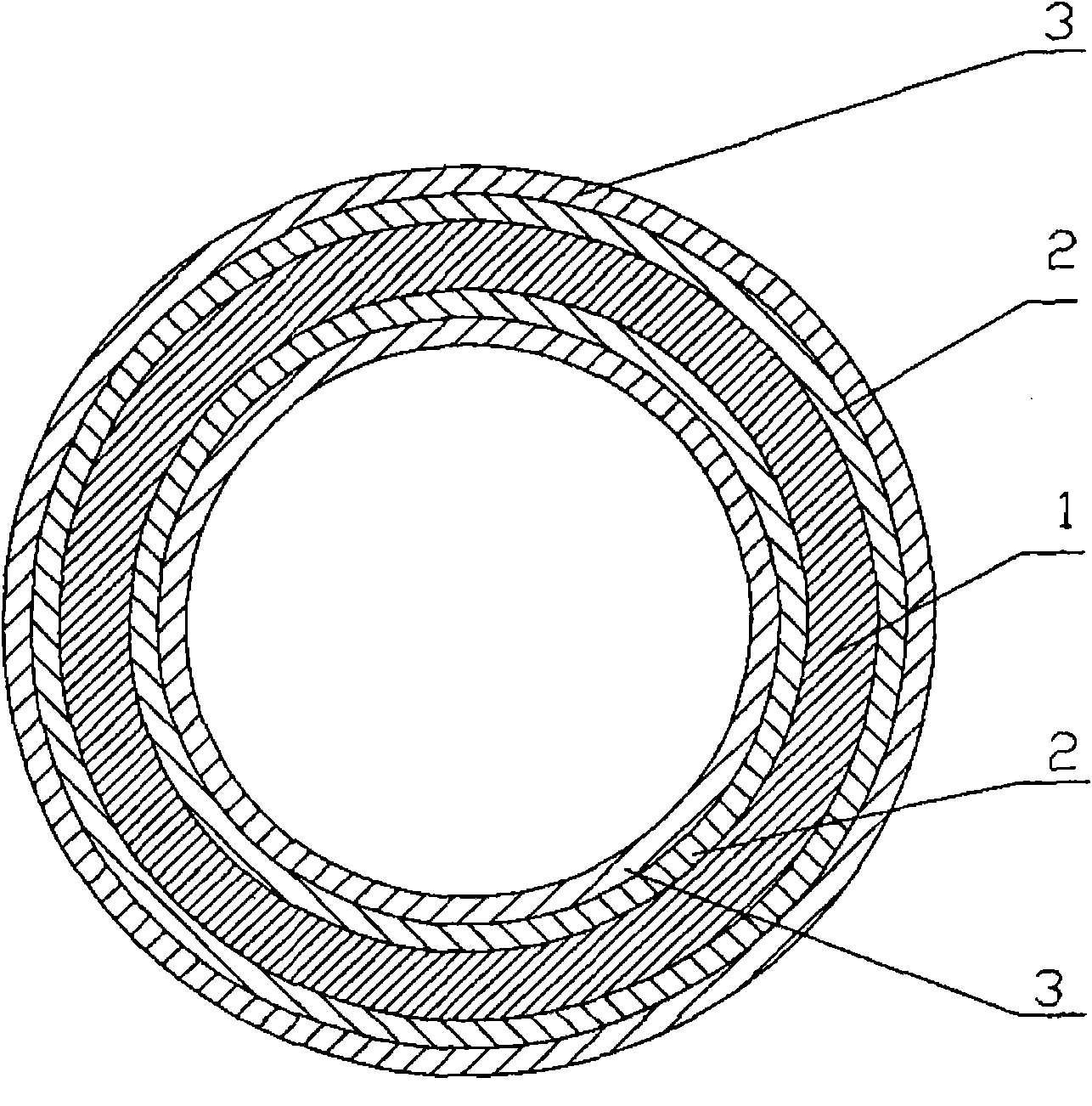

[0009] The present invention will be further explained below in conjunction with the drawings:

[0010] by figure 1 As shown, an anticorrosive pipe provided with an alloy layer includes a pipe body 1, the inner and outer walls of the pipe body 1 are plated with an iron-aluminum multi-element alloy layer 2, and the iron-aluminum multi-element alloy layer 2 is away from the circle of the pipe body 1. The arc surface is provided with a pure alloy layer 3, and the thickness of the iron-aluminum multi-element alloy layer 2 is 80-120 μm.

[0011] The tubing or casing has good corrosion resistance and can ensure that the outer surface will not be layered or fall off during construction and transportation; it is mainly used in polymer flooding oil wells, ternary oil flooding wells, gas flooding oil and gas wells, and strong Corrosion, strong fouling water wells, heavy waxing oil wells, natural gas wells and CO2 injection and production wells, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com