Stainless steel anti-corrosion pipe used for oil gas field and manufacturing method thereof

A stainless steel, oil and gas field technology, applied in arc spraying and other directions, can solve problems such as poor anti-scaling effect and short service life, achieve strong adhesion, high mechanical strength and corrosion resistance, and solve the effect of thread corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

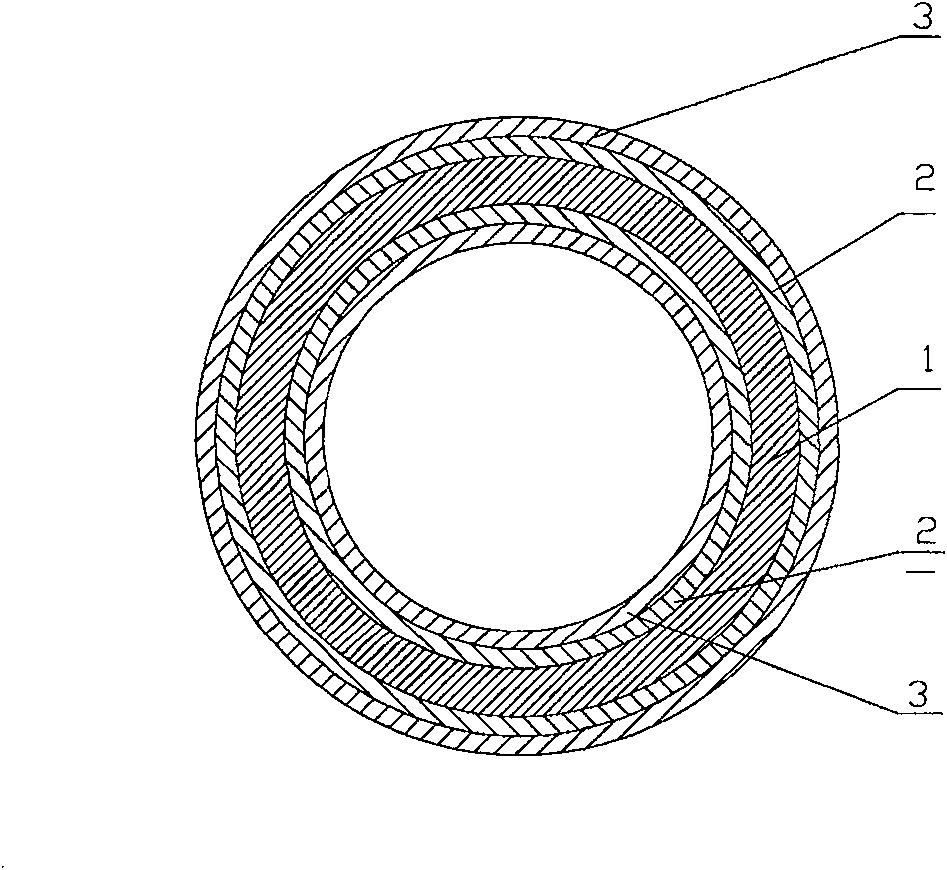

[0010] Below in conjunction with embodiment the present invention will be further described: as figure 1 Shown: by the stainless anticorrosion oil pipe that the present invention makes or casing pipe by oil pipe, casing body (1), oil pipe, casing body (1) iron-aluminum multi-element alloy layer (2), pure alloy layer ( 3) Composition.

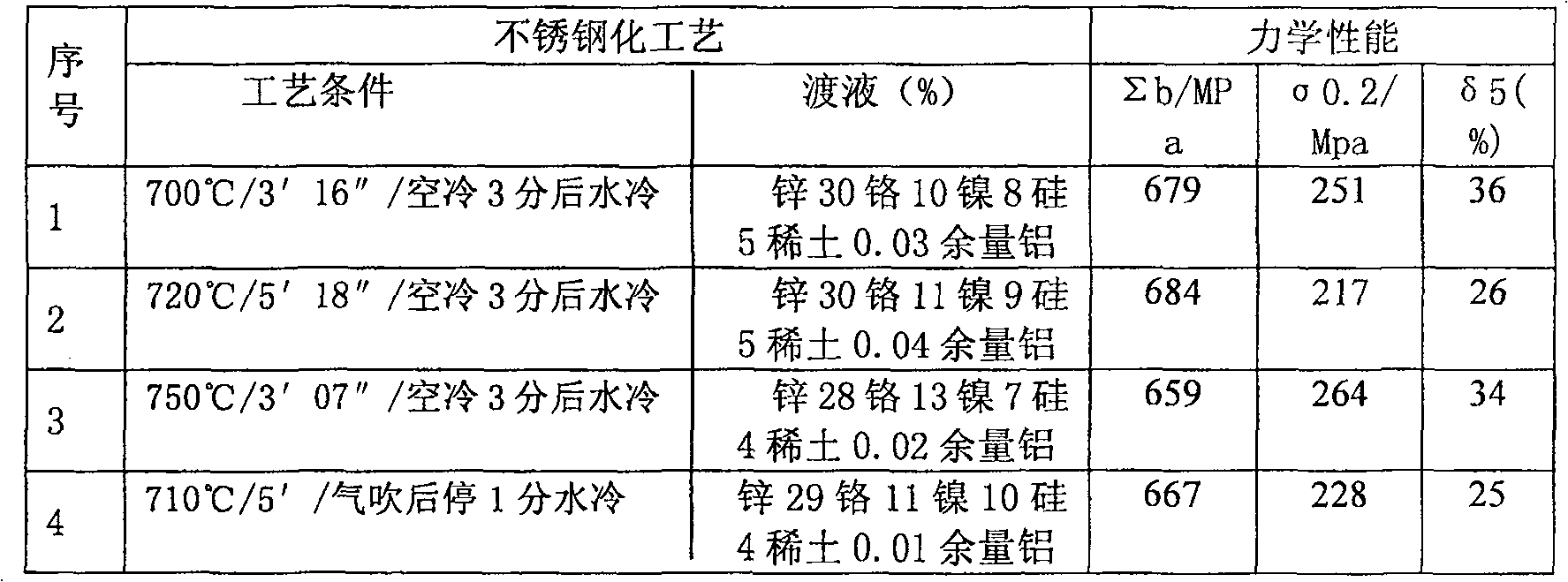

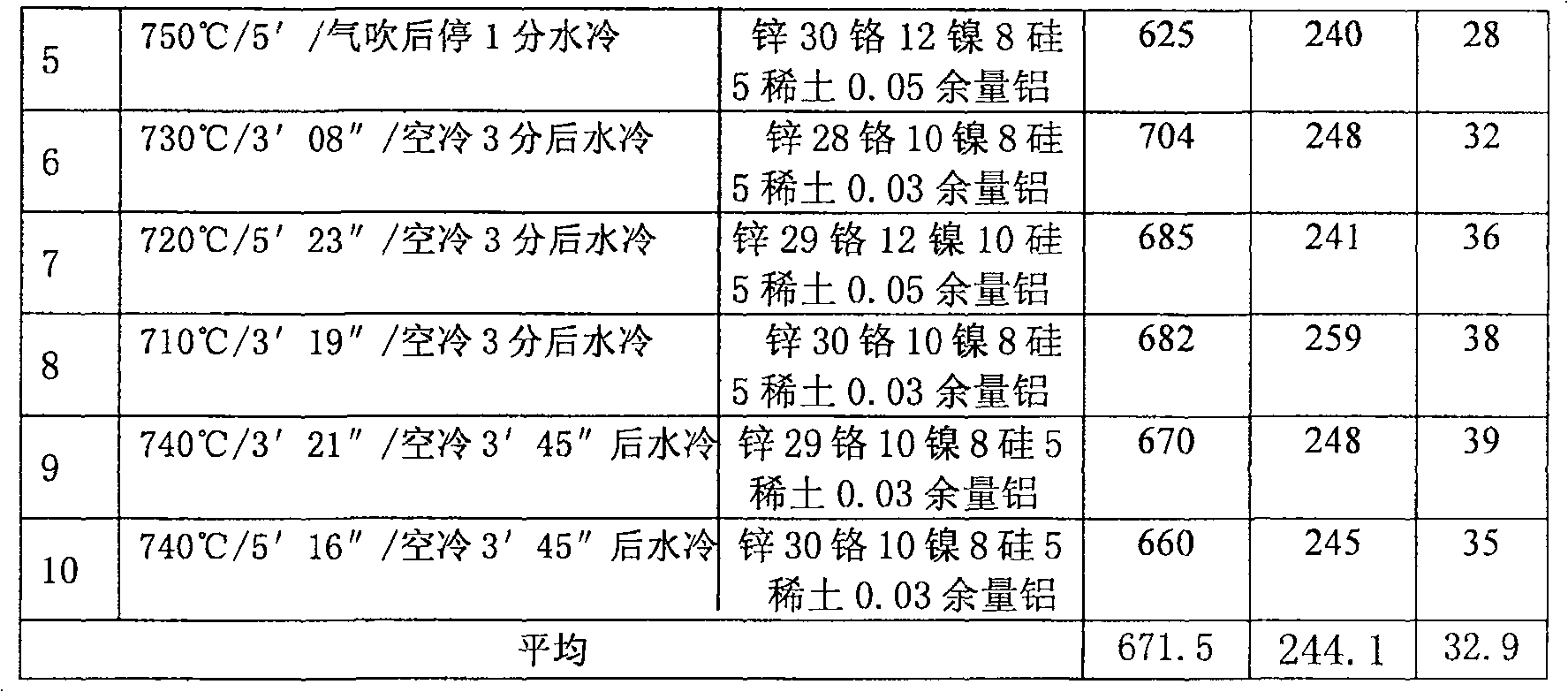

[0011] The prepared stainless steel anti-corrosion oil pipe or casing is processed into a 30cm short joint, and the mechanical performance test is carried out on a mechanical performance testing machine, including tensile strength, yield strength and elongation. And according to GB / T14976-1994 stainless steel seamless steel pipe standard for fluid transportation, comparative analysis is carried out. The experimental method and experimental conditions are based on the GB / T14976-1994 standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com