Special robot motion method with three-dimensional CAD data driving directly

A robot movement, three-dimensional technology, applied in the direction of manipulator, program control manipulator, arc spraying, etc., can solve the problems of unbearable manual operation, low deposition speed, high labor intensity, etc., and achieve the effect of simple motion trajectory control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

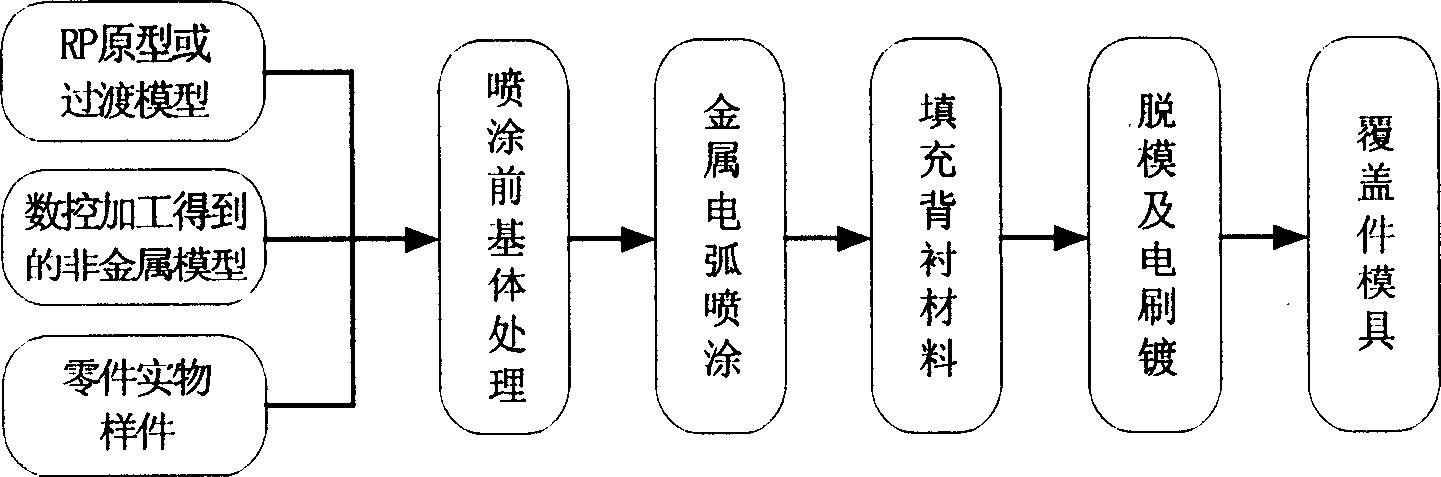

[0025] figure 1 A block diagram of rapid manufacturing technology for arc spraying-brush plating compound forming metal spraying mold is given. The master mold to be sprayed can be RP prototype or transition model, non-metallic model obtained by CNC machining, physical sample of parts, etc. Before spraying, the surface of the master mold is polished (first coat a layer of release agent, and then evenly coat a layer of release agent, let it stand for about 30 minutes), and then spray the mold metal with an arc spray gun to form a thin metal shell with a certain thickness. During the working process, the axis of the spray gun is always perpendicular to the curved surface where the working point is located. After the spraying is completed, the unnecessary parts are cut off, and then the resin, filler and other backing materials are poured into the pre-prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com