Electric arc spraying device suitable for inner wall of pressure vessel

A pressure vessel and arc spraying technology, which is applied in arc spraying, spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of affecting metallurgical components, accelerating electrochemical corrosion, and low efficiency, so as to ensure uniformity and improve Corrosion resistance, the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

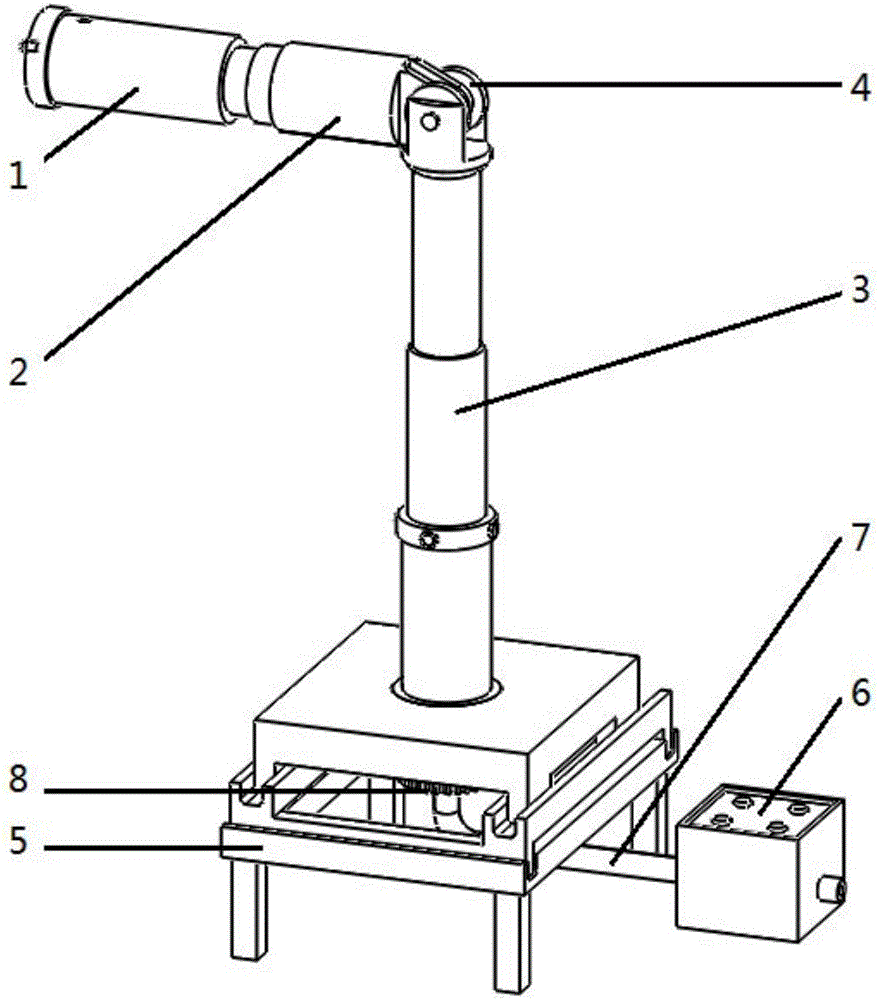

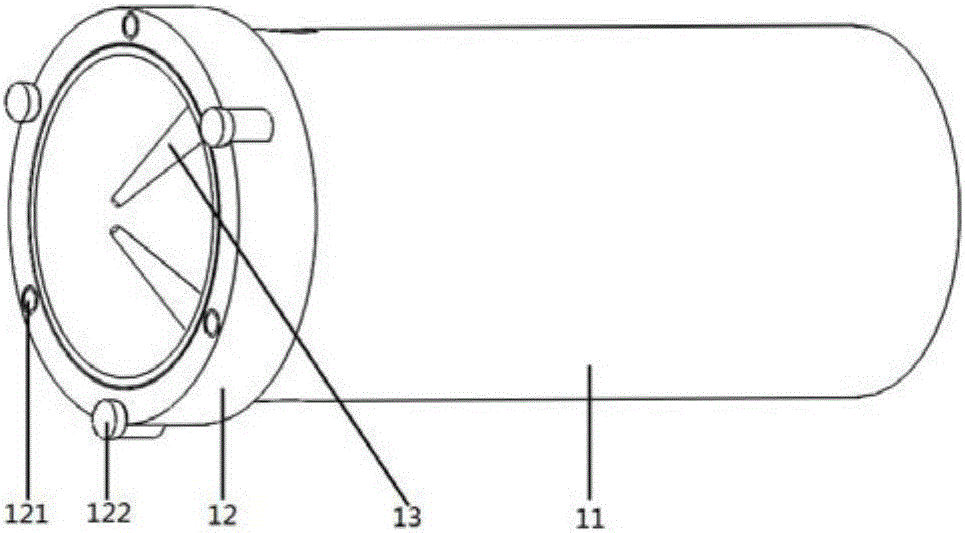

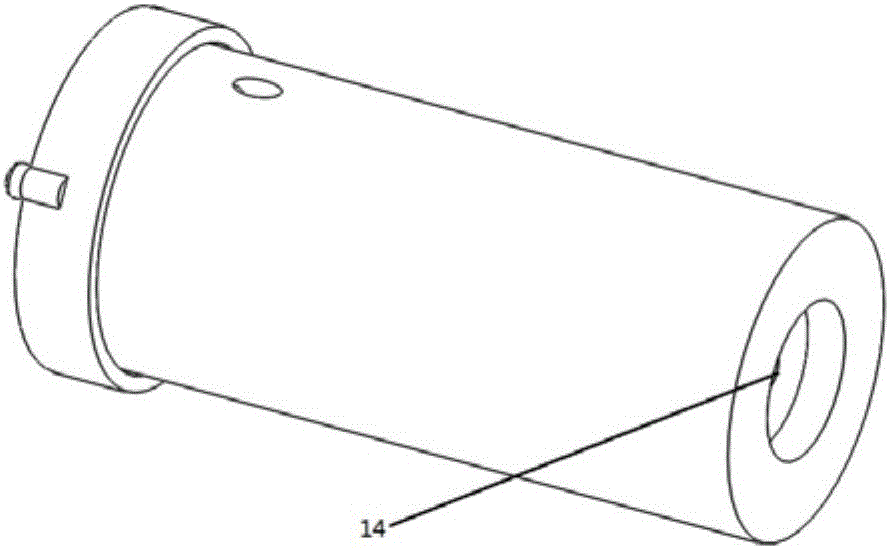

[0019] Such as figure 1 As shown, the arc spraying device suitable for the inner wall of the pressure vessel includes: spray gun 1, swing telescopic shaft 2, rotating telescopic shaft 3, rotating connection mechanism 4, sliding positioning base 5, control box 6, wire material and compressed air delivery pipe 7 , the transmission mechanism 8; the spray gun 1 is installed on the top of the swing telescopic shaft 2, the swing telescopic shaft 2 is connected with the rotation telescopic shaft 3 through the rotation connection mechanism 4, the swing telescopic shaft 2 can be in the vertical state and the rotation of the rotation connection mechanism 4 Rotate within a range of 90° between horizontal states; the rotating telescopic shaft 3 is installed on the platform of the sliding positioning base 5, the wire and compressed air delivery pipe 7 runs through the rotating telescopic shaft 3 and the swinging telescopic shaft 2, and the wire and compressed air The delivery pipe 7 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com