Austenitic heat-resisting stainless steel welding electrode for ultra-supercritical thermal power units

A heat-resistant stainless steel, thermal power unit technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of limited high-temperature oxidation and corrosion resistance, insufficient high-temperature lasting strength, and large tube wall thickness. Achieve excellent mechanical properties and good welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

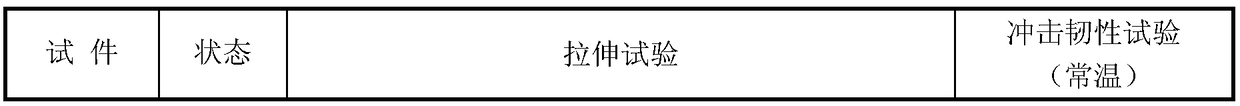

Embodiment 1

[0038] The general manufacturing process in the welding rod production industry is adopted, the welding core is selected according to the requirements of the welding core composition, the raw materials of the coating are prepared in proportion, and the welding rod coating is prepared by dry mixing and wet mixing, and the welding rod coating is applied to the welding core. The molding:

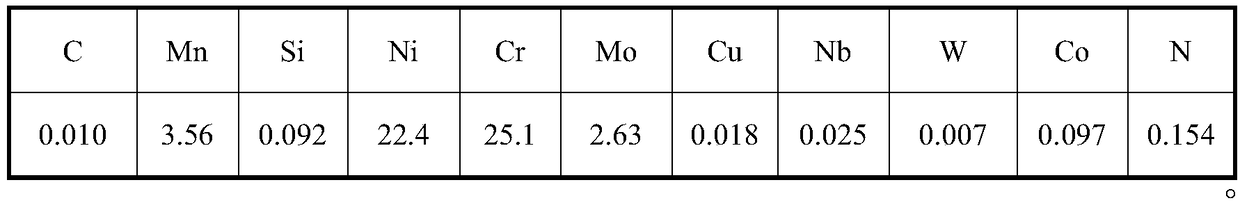

[0039] Table 1-1 Weld core composition (unit: weight percentage)

[0040]

[0041] Table 1-2 Drug skin composition ratio (unit: weight percentage)

[0042] marble

Chrome powder

Tungsten powder

iron iron

15

10

16

5

3

5

1

4

7

4

15

7

margin

[0043] Table 1-3 The chemical composition of the deposited metal (unit: %), the balance is Fe and impurities

[0044] C

mn

Si

Ni

...

Embodiment 2

[0049] The general manufacturing process in the welding rod production industry is adopted, the welding core is selected according to the requirements of the welding core composition, the raw materials of the coating are prepared in proportion, and the welding rod coating is prepared by dry mixing and wet mixing, and the welding rod coating is applied to the welding core. The molding:

[0050] Table 2-1 Composition of welding core wire (unit: weight percentage)

[0051] C

mn

Si

Ni

Cr

Mo

Cu

Nb

W

co

N

0.011

3.52

0.088

22.2

25.4

2.60

0.017

0.026

0.007

0.094

0.152

[0052] Table 2-2 Drug skin composition (unit: weight percentage)

[0053] marble

copper powder

Chrome powder

nickel powder

Tungsten powder

16

11

17

6

3

5.5

1

4

6.5

...

Embodiment 3

[0060] The general manufacturing process in the welding rod production industry is adopted, the welding core is selected according to the requirements of the welding core composition, the raw materials of the coating are prepared in proportion, and the welding rod coating is prepared by dry mixing and wet mixing, and the welding rod coating is applied to the welding core. The molding:

[0061] Table 3-1 Weld core composition (unit: weight percentage)

[0062] C

mn

Si

Ni

Cr

Mo

Cu

Nb

W

co

N

0.010

3.53

0.091

22.3

25.3

2.61

0.018

0.024

0.008

0.095

0.150

[0063] Table 3-2 Drug skin formula (unit: weight percentage)

[0064] marble

copper powder

Chrome powder

nickel powder

Tungsten powder

16

10

17

5.5

2.5

5

1

4.5

7

4

14

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com