Fluorine alkaline sintered flux and preparation method and application thereof

A technology of sintering flux and controller, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of oxide slag inclusion, pores, cracks, not suitable for X70 pipeline steel, impact toughness, etc., to achieve easy slag removal , Easy to operate, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

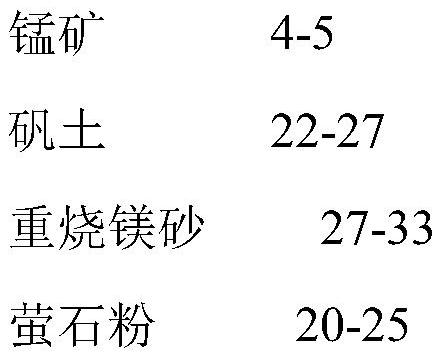

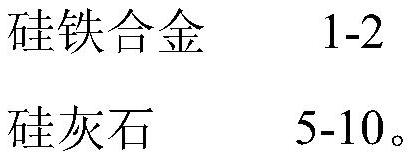

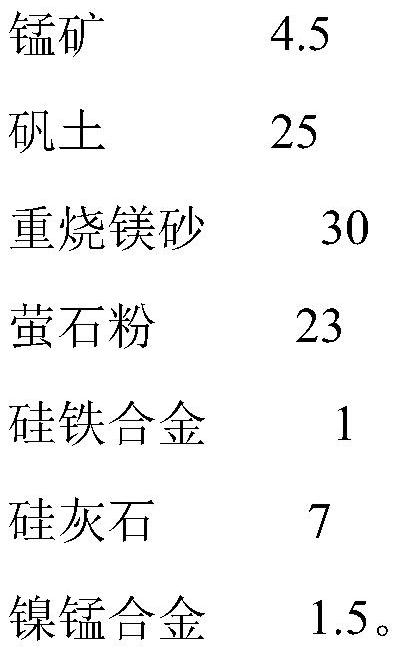

Method used

Image

Examples

preparation example 1

[0043] Preparation of nickel manganese alloy:

[0044] S1: Take 1 part by weight of nickel and 3 parts by weight of manganese, respectively add them to the crucible in the high-temperature evaporator, check that the airtightness of the reaction system is qualified, vacuumize the reaction system, and then open the nitrogen gas arranged at the bottom of the high-temperature evaporator Valve, the reaction system is filled with nitrogen, so that the atmosphere in the reaction system is inert and the internal pressure of the reaction system is 1.4 atmospheres;

[0045] S2: Turn on the plasma gun arranged on the top of the high-temperature evaporator, use the generated high-frequency plasma nitrogen as a heating source to heat and evaporate the nickel and manganese raw materials, and heat the nickel and manganese raw materials to a boiling state to form nickel vapor and manganese vapor. A mixed vapor of nickel vapor and manganese vapor is formed in the high-temperature evaporator, a...

Embodiment 1

[0049]Weigh each raw material by weight, be placed in mixer, add the potassium sodium water glass of 21 weight parts and carry out mechanical stirring 5min; After stirring, enter granulator and carry out granulation, enter drying machine after and dry; Screening is carried out, and materials with a particle size of 10-40 mesh are taken into a sintering furnace for sintering at a temperature of 850°C. The sintered materials are placed in a cooling cylinder for natural cooling to obtain the product. The specific raw materials and dosage are shown in Table 1.

Embodiment 2

[0051] Take each raw material by weight, be placed in mixer, add the potassium sodium water glass of 23 weight parts and carry out mechanical stirring 5min; After stirring, enter granulator and carry out granulation, enter drying machine after and dry; Screening is carried out, and materials with a particle size of 10-40 mesh are taken into a sintering furnace for sintering at a temperature of 810°C. The sintered materials are placed in a cooling cylinder for natural cooling to obtain the product. The specific raw materials and dosage are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com