Novel self-shielded flux-cored wire for submerged arc welding

A technology of flux-cored welding wire and submerged arc welding, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of low melting point of slag, high melting point of slag, and low density, and achieve stable arc combustion , good arc stability and good forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

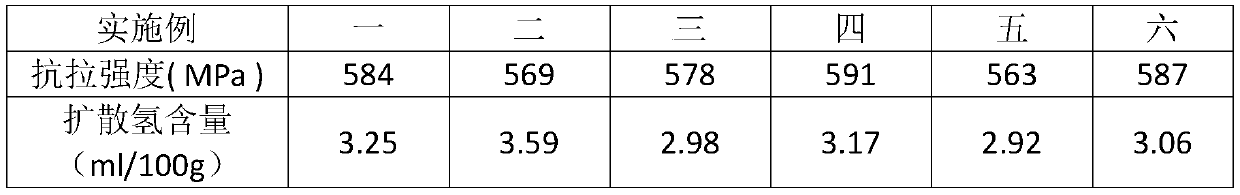

Examples

Embodiment Construction

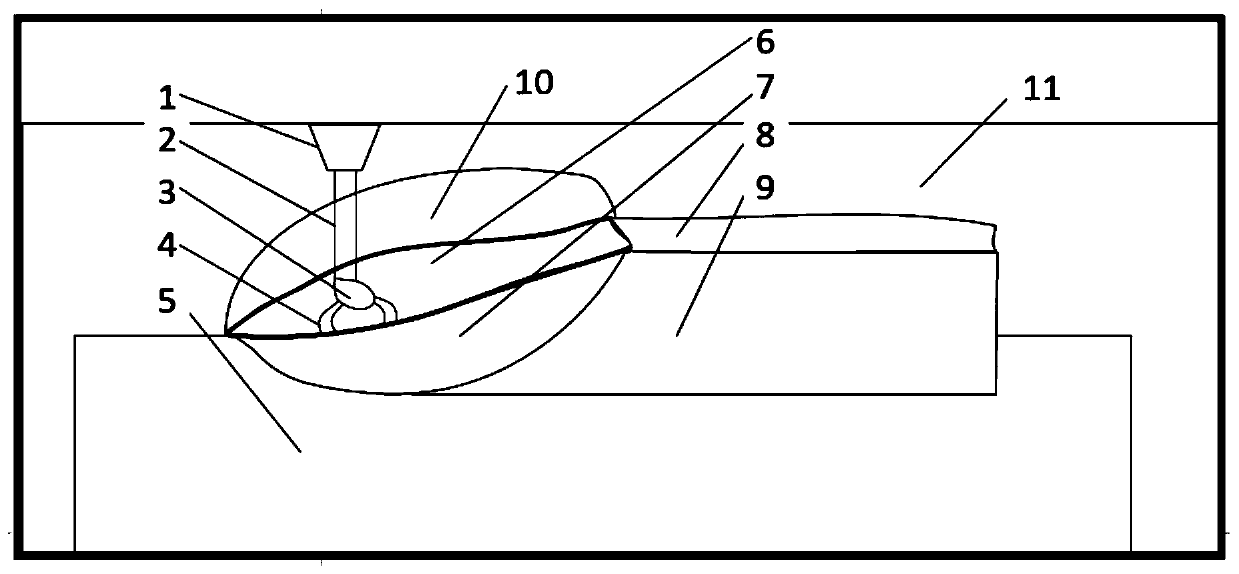

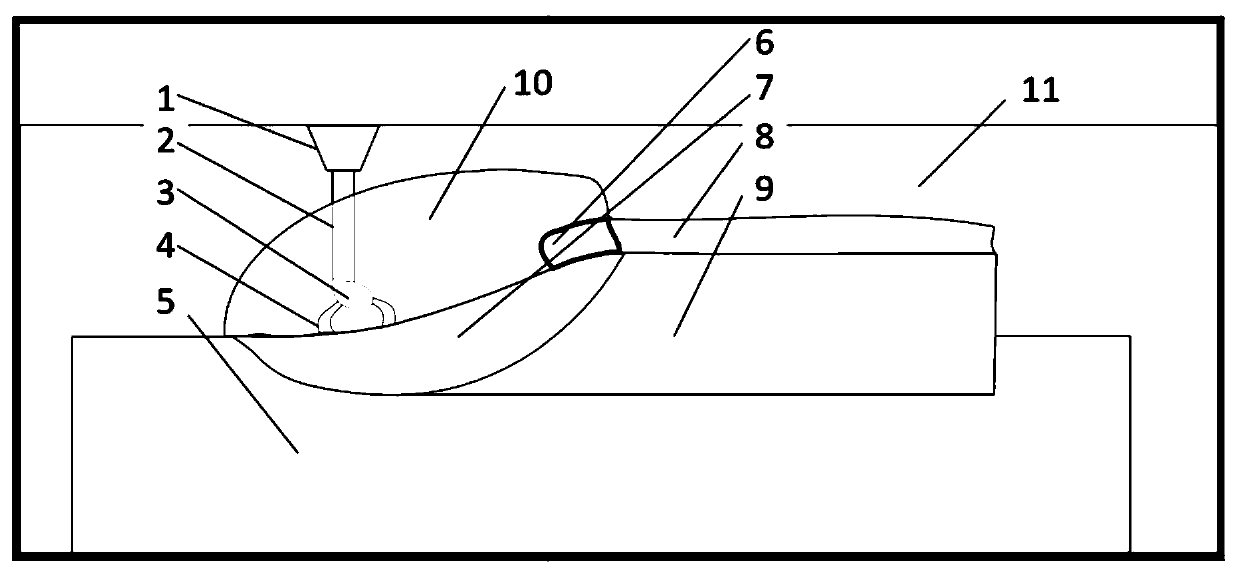

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] figure 1 As shown, the new type submerged arc welding self-shielding flux-cored welding wire 2 of the present invention uses the neutral fluoride-rutile slag system as the core base slag system, and by adjusting the ratio of fluoride and rutile, the flux-cored welding wire 2 is During the welding process, the combustion of the arc 4 is carried out under the liquid slag 6, and the arc 4 is not affected by the disturbance of the water environment 11, so the combustion of the arc 4 is stable, and the arc break phenomenon is not easy to occur; Under the slag 6, when the droplet 3 has a tendency to splash when disturbed by the arc air bag 10, the droplet 3 will not leave the welding area to form splash due to the obstruction of the package of the liquid slag 6; Under protection, the gas such as hydrogen in the water environment 11 will not enter the molten drop 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com