Permanent magnet hall thruster ignition device

A Hall thruster and ignition device technology, applied in the direction of thrust reverser, machine/engine, and plasma utilization, can solve the problems of wasting space resources, difficulty for electrons to enter the discharge channel, and difficult realization of thruster arcing, etc., to achieve The effect of convenient arc starting and saving space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

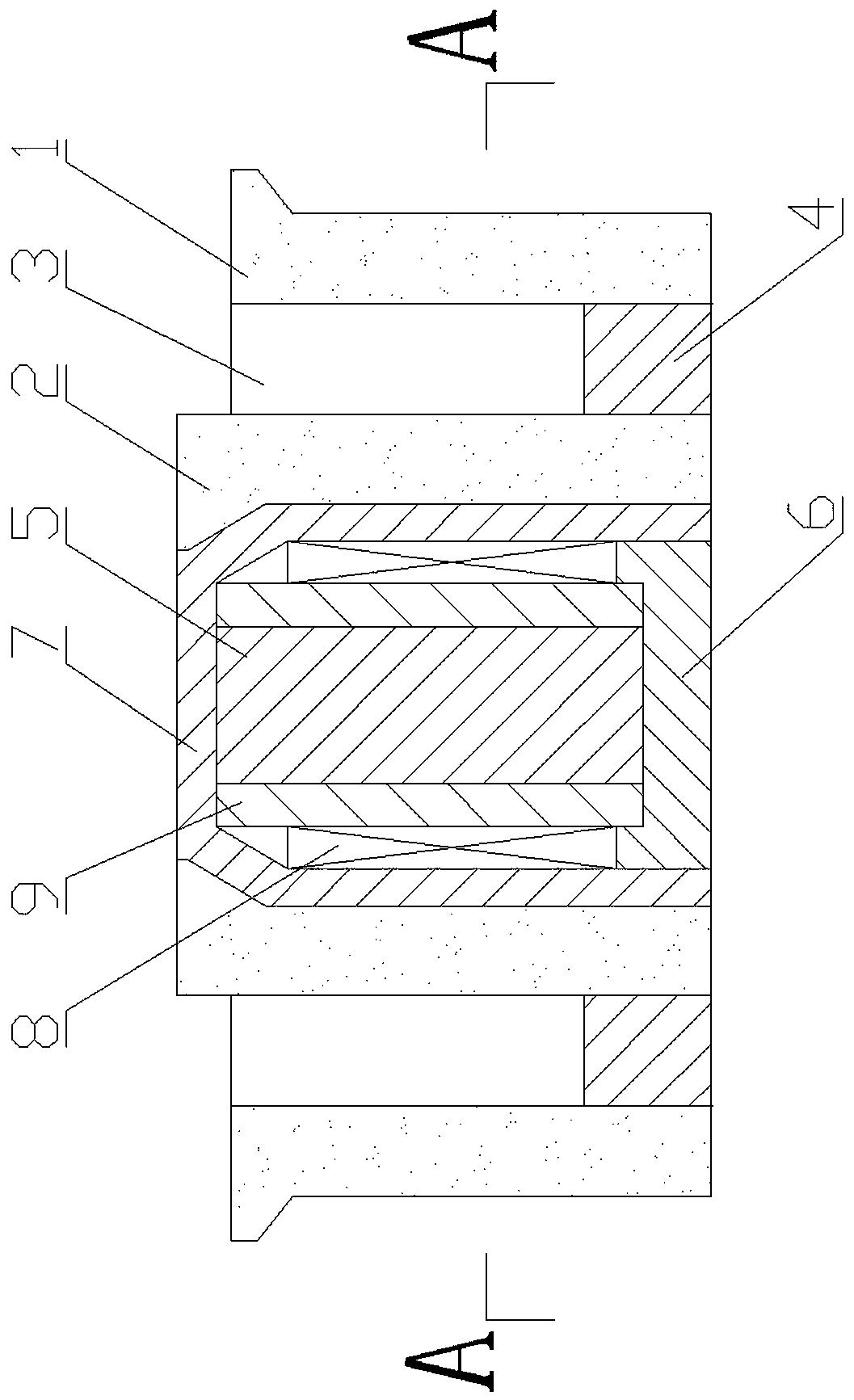

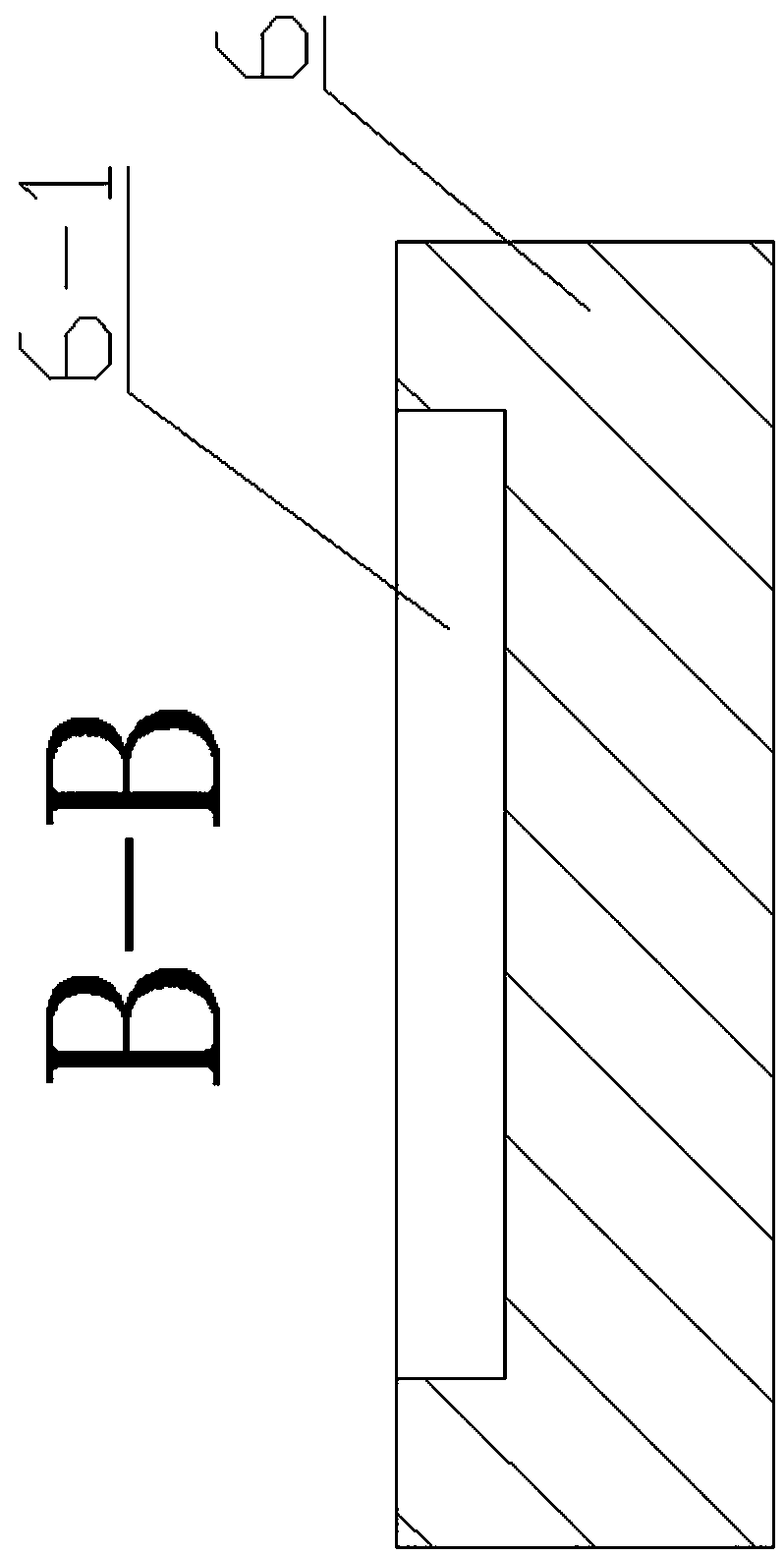

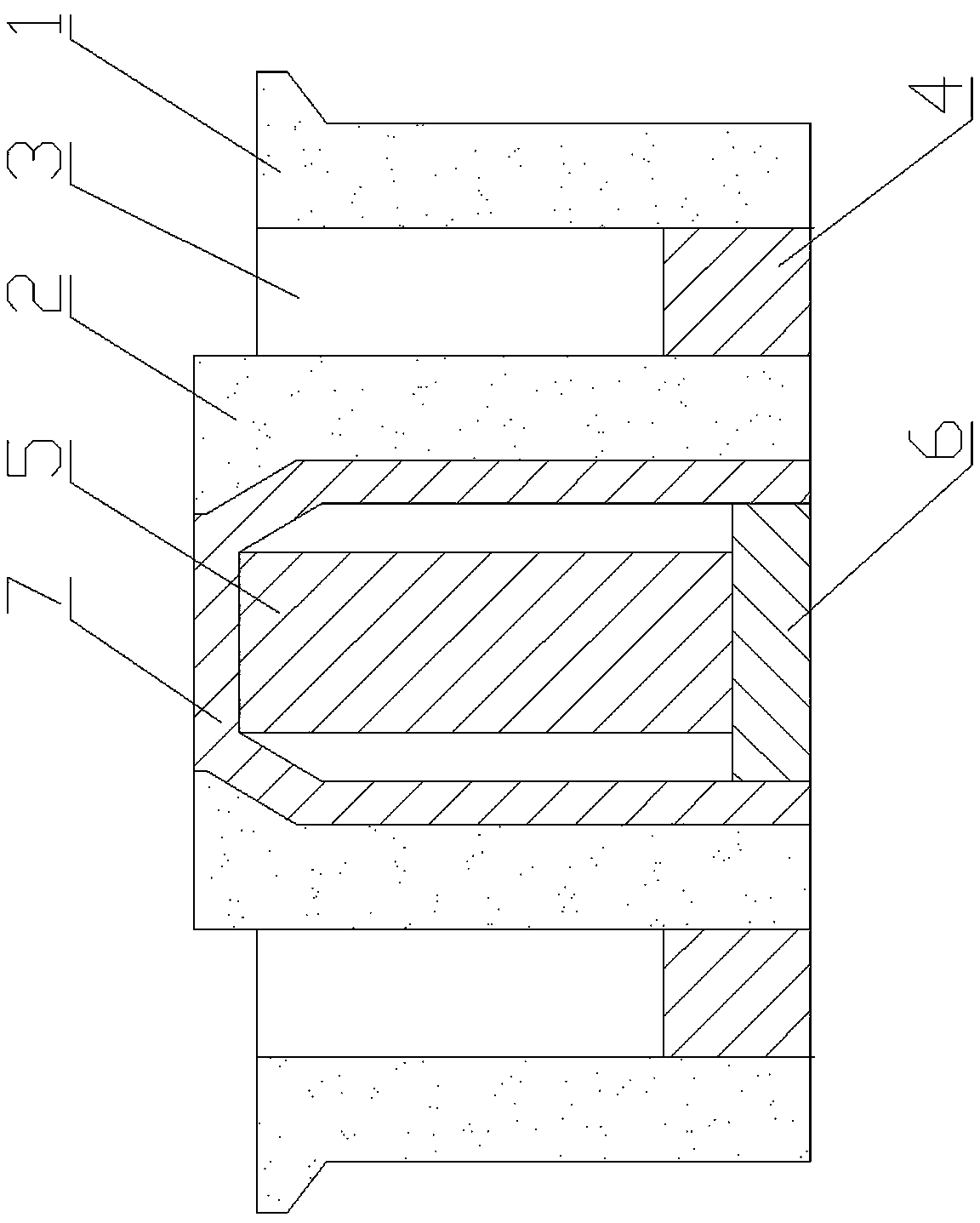

[0023] Examples such as Figure 1-4 As shown, the permanent magnet Hall thruster ignition device includes an outer ceramic ring 1 , an inner ceramic ring 2 , an anode assembly 4 , a magnetic steel 5 , a magnetically conductive base 6 and a magnetic steel sleeve 7 . The outer wall of the anode assembly 4 is installed on the lower end of the inner wall of the outer ceramic ring 1 by extrusion, and the lower end of the outer wall of the inner ceramic ring 2 is installed on the inner wall of the anode assembly 4 by extrusion, between the inner wall of the outer ceramic ring 1 and the outer wall of the inner ceramic ring 2 An annular discharge channel 3 is formed, the magnetic steel sleeve 7 is installed on the inner wall of the inner ceramic ring 2 by extrusion, the outer wall of the magnetic base 6 is installed on the lower end of the inner wall of the magnetic steel sleeve 7 by extrusion, and the magnetic steel 5 is installed on the magnetic In the steel sleeve 7 , the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com