Active additive used for solid welding wire free of plated copper and preparation method thereof

An active additive, solid welding wire technology, used in welding equipment, metal processing equipment, welding media, etc., can solve the problems of abnormal welding work, affecting the stability of wire feeding, clogging of wire feeding hoses, etc., to achieve anti-rust and Good lubricating effect, improving welding efficiency and avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The active additive for copper-free solid welding wire is made from the following raw materials: 90.8 kg of palm oil, 5 kg of cesium powder, 1 kg of tellurium powder, 3 kg of lithium hydroxide, and 0.2 kg of sodium hydroxide.

[0030] The preparation method of the active additive for copper-free solid welding wire adopts the following steps: adding palm oil to a stirring pot and heating to 80° C., maintaining a constant temperature of 80° C. for 2 hours and fully stirring; respectively adding cesium powder, tellurium powder and lithium hydroxide Put into the drying box with sodium hydroxide and dry to remove moisture, then add the dried cesium powder, tellurium powder, lithium hydroxide and sodium hydroxide of the above-mentioned weight into the vegetable oil respectively and continue stirring at a constant temperature of 80 ° C for 2 hours, then the When the temperature is lowered to room temperature, the active additive for the copper-free solid welding wire of the pre...

Embodiment 2

[0033] The active additive for copper-free solid welding wire is made from the following raw materials: 90 kg of palm oil, 3 kg of cesium powder, 0.8 kg of tellurium powder, 2 kg of lithium hydroxide, and 0.5 kg of sodium hydroxide.

[0034] The preparation method and use method are the same as those in Example 1.

Embodiment 3

[0036] The active additive for copper-free solid welding wire is made from the following raw materials: 93 kg of palm oil, 4 kg of cesium powder, 2 kg of tellurium powder, 2.5 kg of lithium hydroxide, and 0.8 kg of sodium hydroxide.

[0037] The preparation method and use method are the same as those in Example 1.

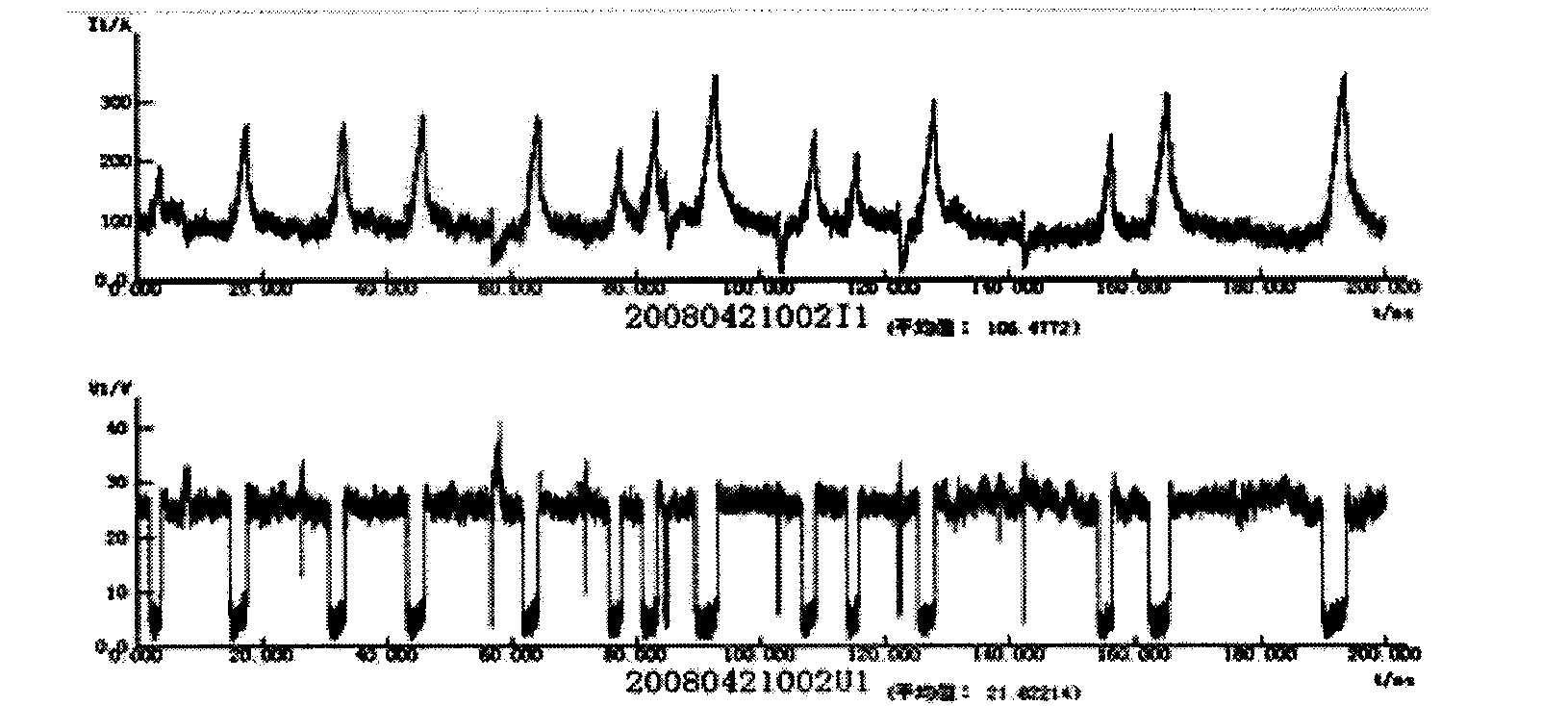

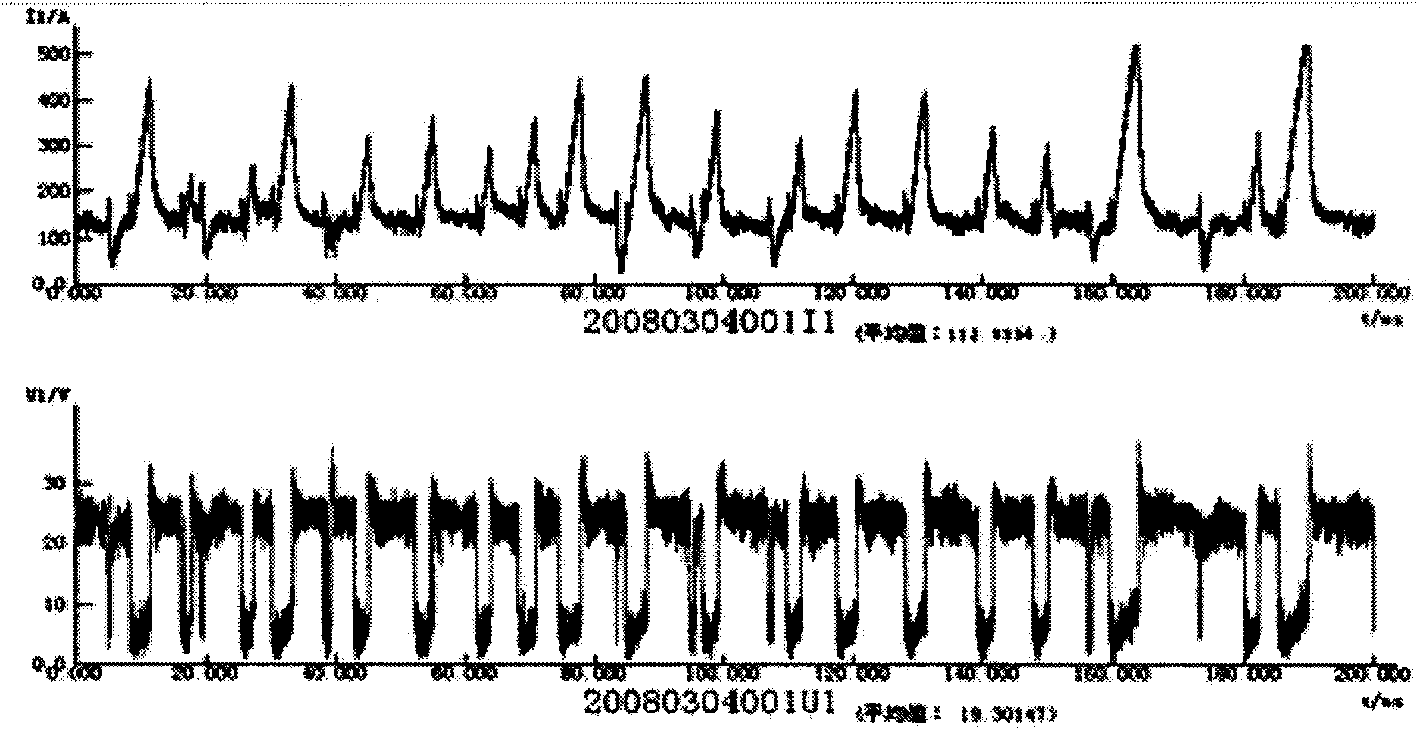

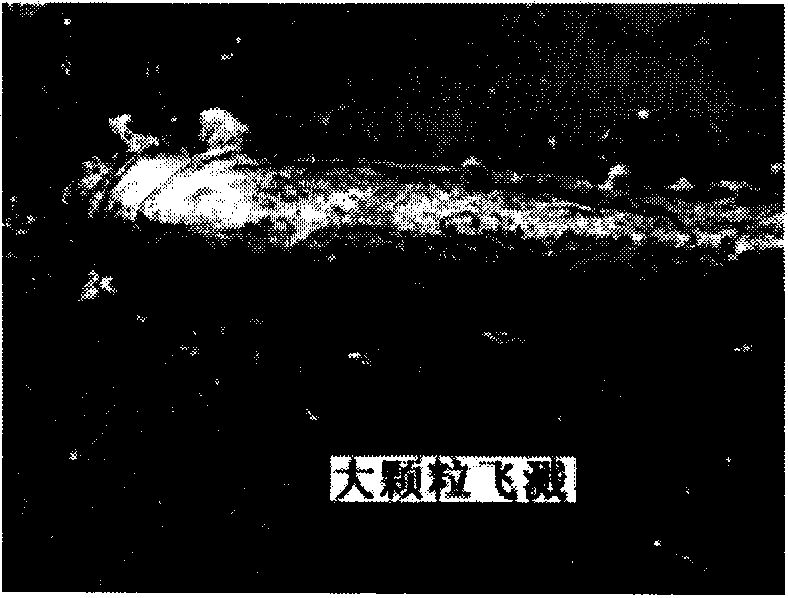

[0038] The active additive for the copper-free solid welding wire of the present invention adopts palm oil, because palm oil has better anti-rust and lubricating properties. After the surface of the wire rod is rust-removed, it is then subjected to texturing treatment, and then the wire is passed through the active additive for the non-copper-plated solid welding wire of the present invention, and then the pressure die is drawn to obtain the non-copper-plated solid welding wire. Compared with the existing copper-plated welding wire, the copper solid welding wire has less spatter in welding, and the most direct performance in the appearance of the welding seam is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com