Ice adding system and method for stirring station

A technology of mixing station and mixer, applied in mixing plants, cement mixing devices, chemical instruments and methods, etc., can solve the problems of high cost, low reliability, waste of equipment, etc., and achieve guaranteed temperature control, high reliability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

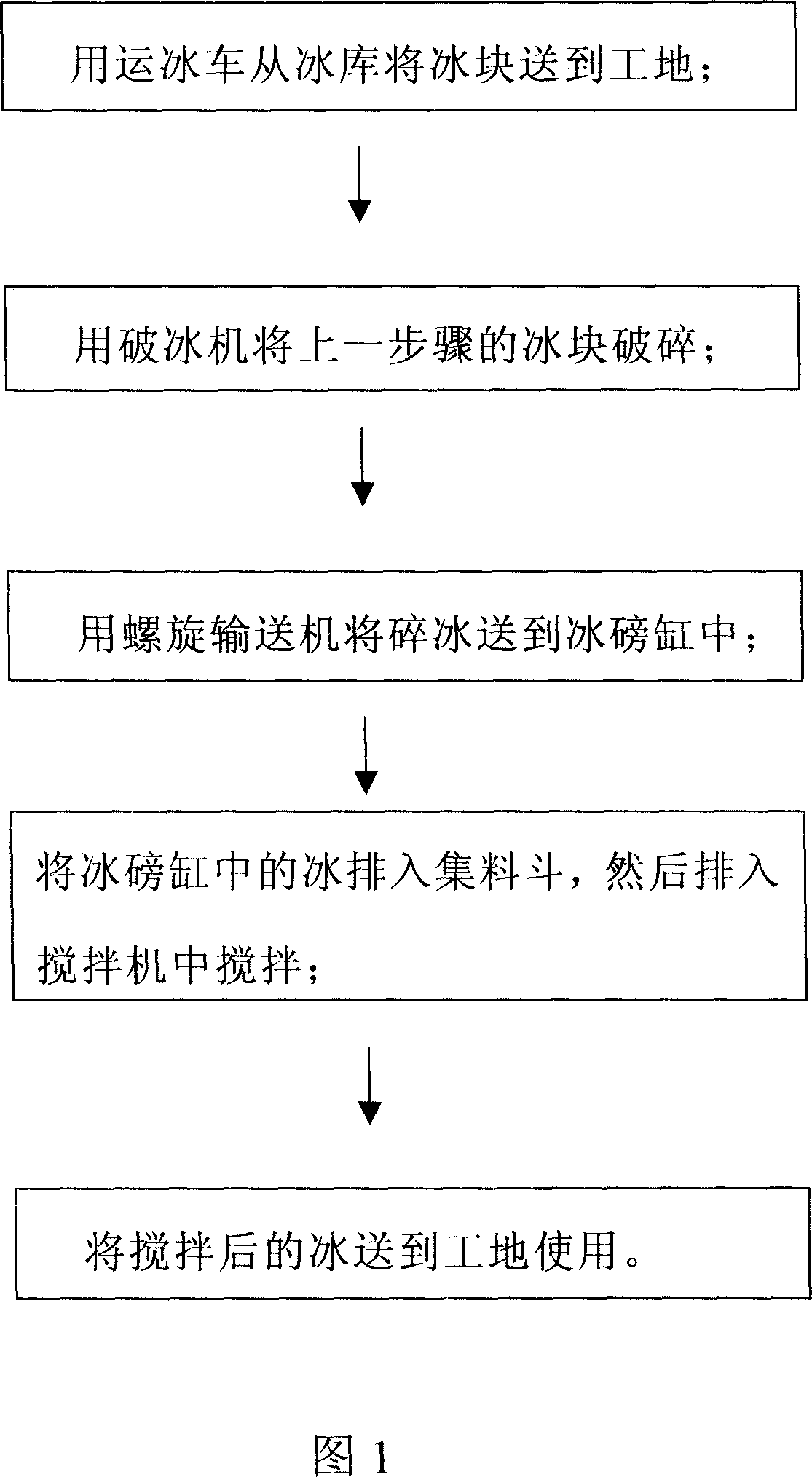

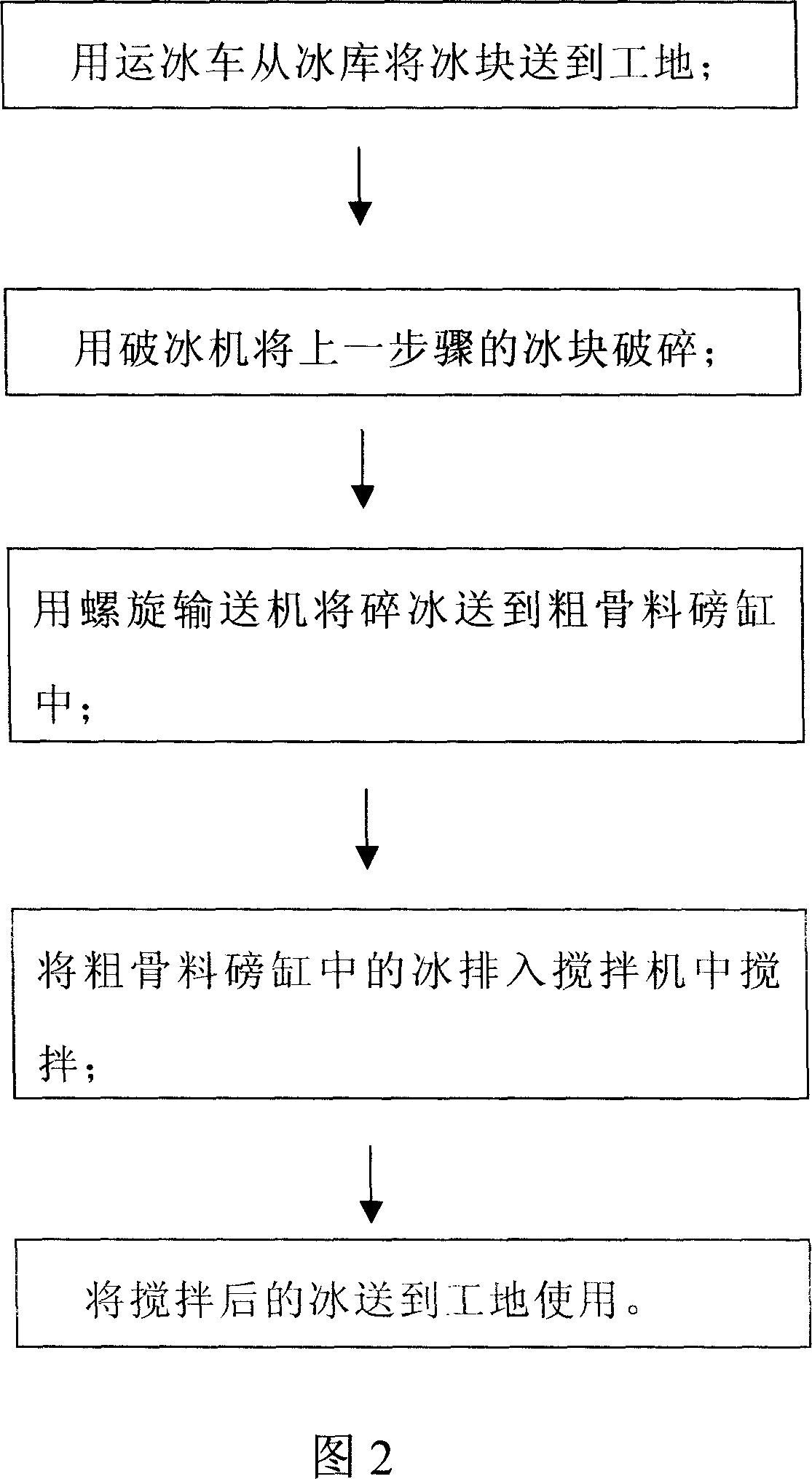

[0042] The second embodiment of the method for adding ice of the present invention includes the following steps:

[0043] Step 1: Send the ice cubes from the ice storage to the construction site with an ice truck;

[0044] Step 2: Use an ice breaker to break the ice cubes in the previous step;

[0045] The particle size of crushed ice is controlled below 5mm.

[0046] Step 3: Send the crushed ice to the coarse aggregate pounding cylinder with a screw conveyor;

[0047] Step 4: Drain the ice in the coarse aggregate pound cylinder into the blender and stir;

[0048] Step 5: Send the stirred ice to the construction site for use.

[0049] The invention adopts the method of crushing purchased ice cubes, which can save a lot of expenses, reduce costs, be economical and practical, have high reliability, and ensure the temperature control of iced concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com