Automobile wheel hub continuous automatic quenching device

A technology of automobile wheel hub and quenching device, which is applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problems of quenching continuity, stability and accuracy that cannot guarantee high quality and high-demand batch products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

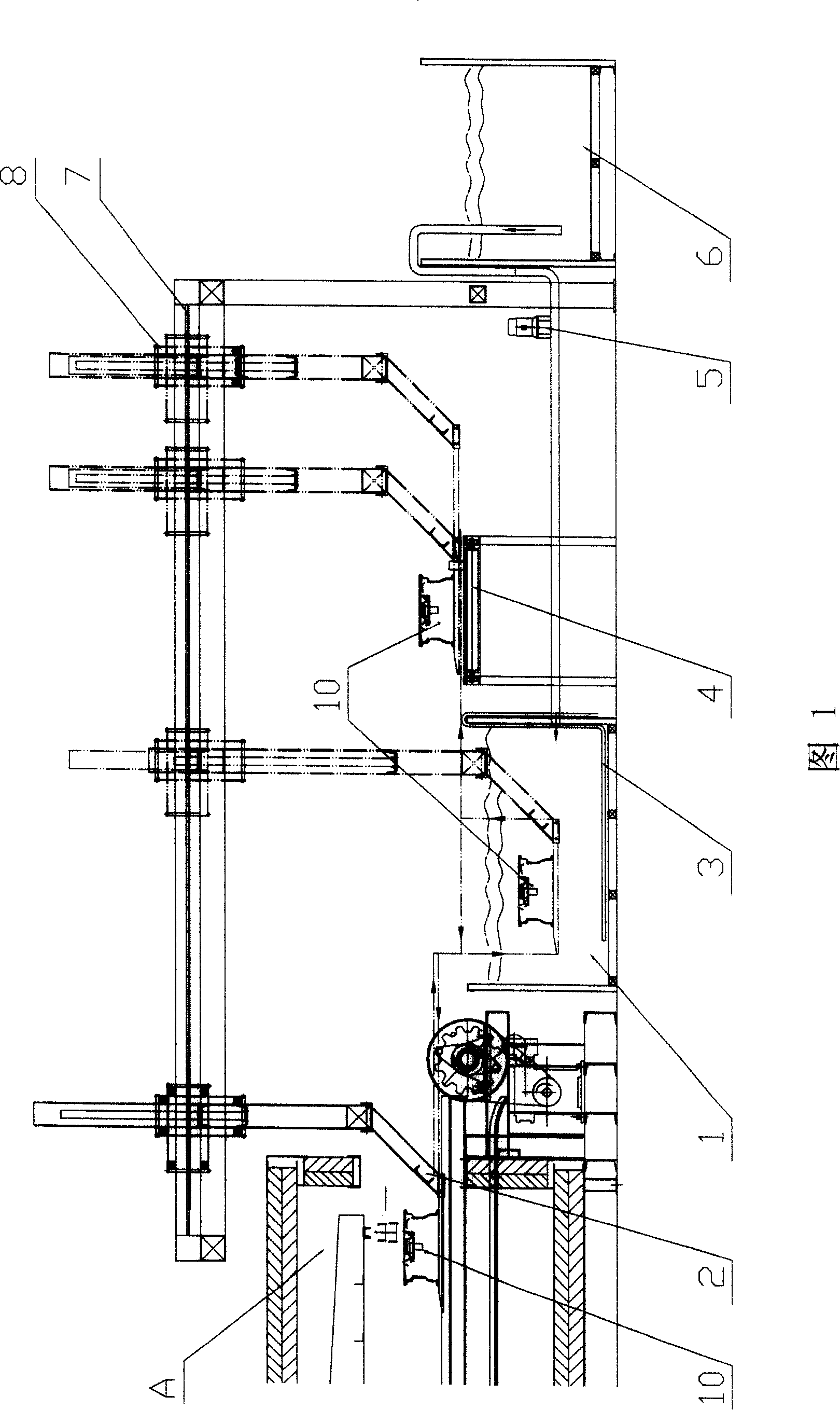

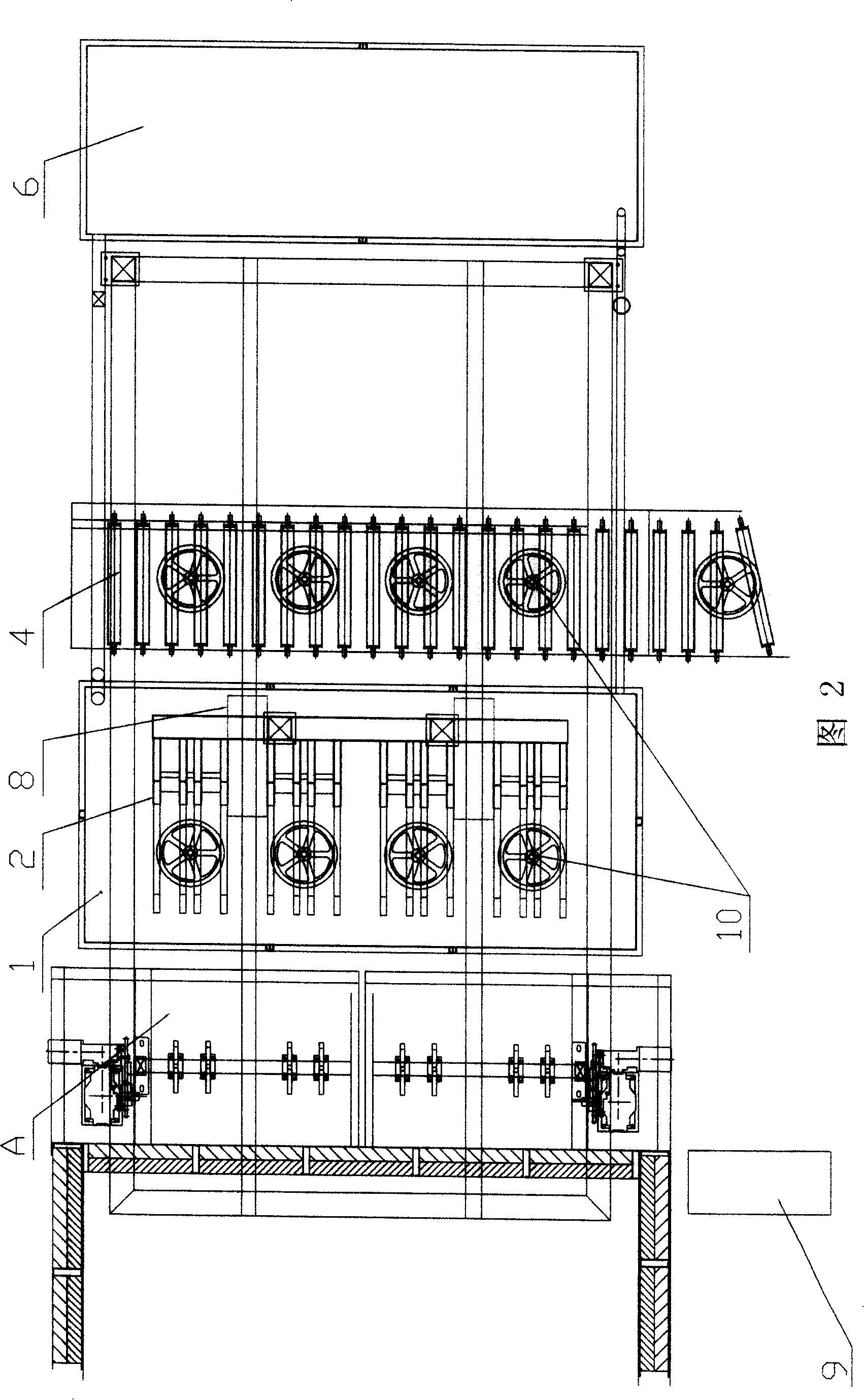

[0009] Below in conjunction with accompanying drawing, the implementation process of the continuous type automatic quenching device for automobile hub of the present invention is further described:

[0010] As shown in Fig. 1 and Fig. 2, the quenching water tank 1 of the continuous automatic quenching device for automobile hubs of the present invention is located at the exit of the continuous heat treatment furnace A for automobile hubs, and the heat treatment furnace A has 4 conveyor belts in parallel to deliver 4 automobile hubs simultaneously for quenching. There are four parallel forks 2 arranged above the water tank 1, and a positioning mechanism 7 and a brake 8 are arranged on the forks 2 to control the up and down movement of the forks 2; the water temperature equalization pipe 3 is located at the bottom of the quenching water tank 1 to ensure the setting of the quenching water tank 1 The temperature remains unchanged; the automatic unloading raceway 4 composed of parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com