Multi-field coupling true triaxial test system and experiment method implemented by same

A test system, true triaxial technology, applied in the test field of indoor test research in complex working conditions, can solve the problem of affecting the accuracy and effectiveness of the test temperature field control, it is difficult to find a test system for rock and soil media, and reduce the accuracy of test results To achieve the effect of simple and reasonable design structure, improve effectiveness and accuracy, and reduce uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

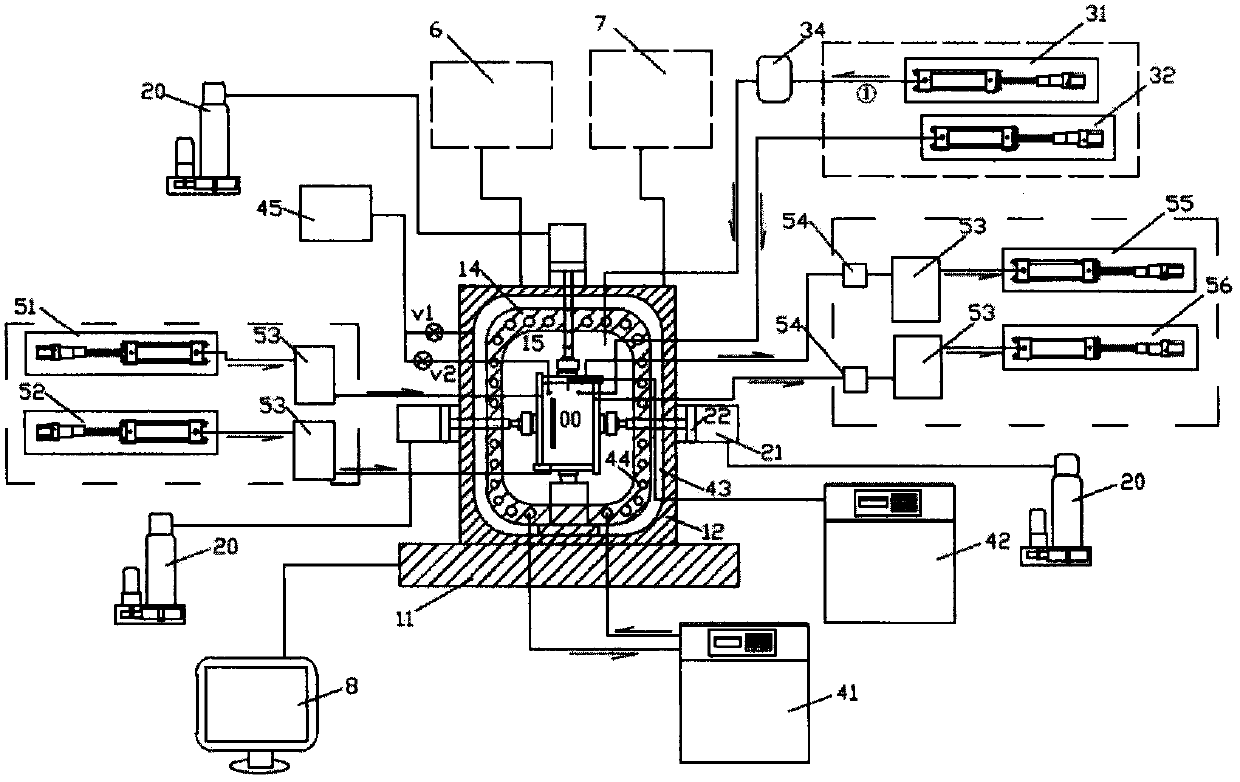

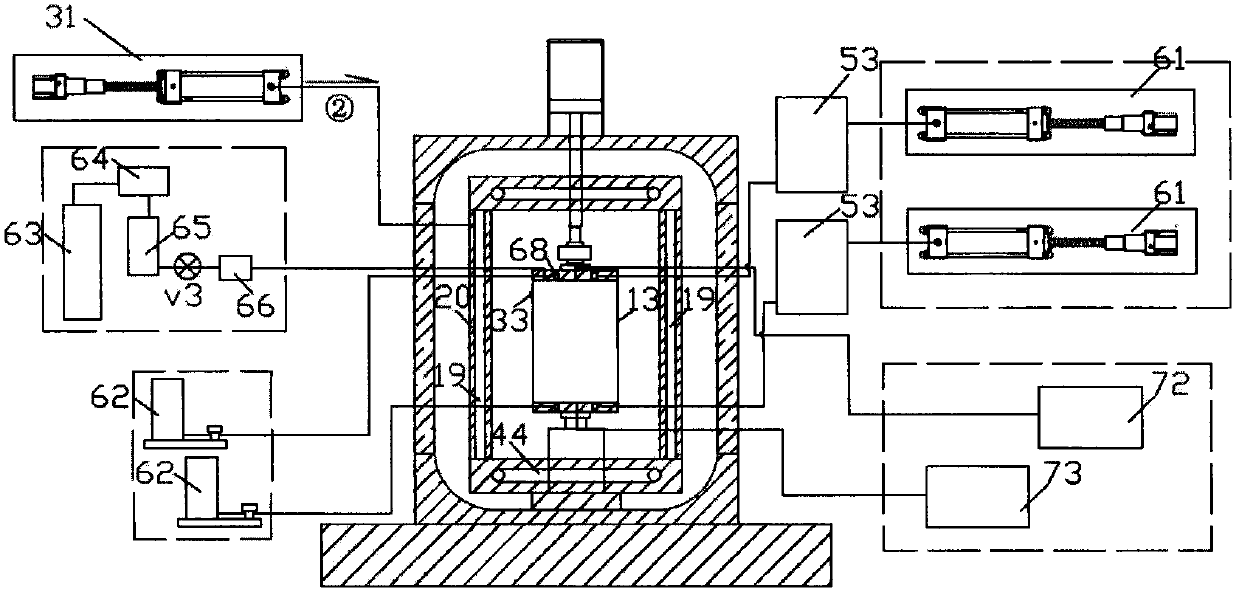

[0051] The present invention consists of a true triaxial double chamber pressure chamber 1, an axial loading system 2, a confining pressure / back pressure loading system 3, a temperature control system 4, a permeation control system 5, a gas loading system 6, a bending element test system 7 and a computer 8 ;

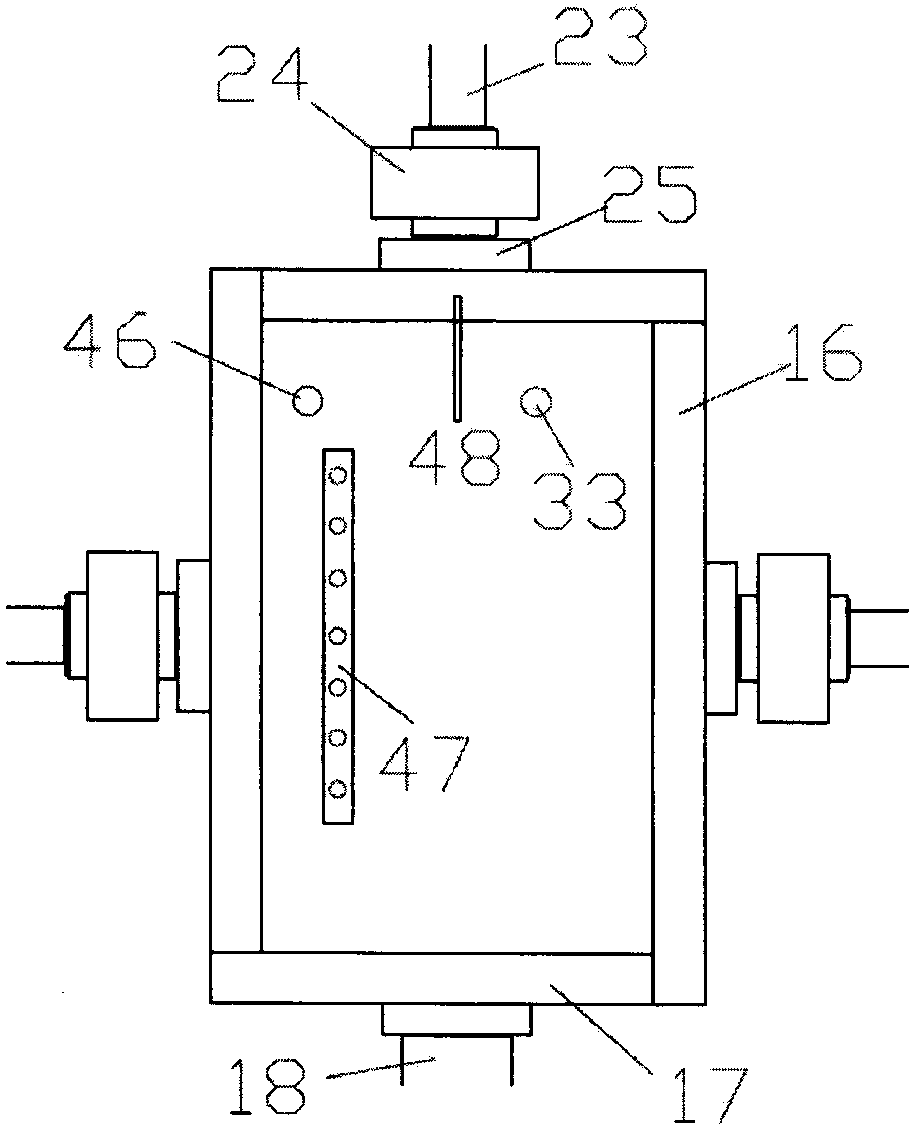

[0052] The true triaxial double-chamber pressure chamber 1 is fixed on the pressure chamber base 11, and the pressure chamber wall 12 outside the pressure chamber is bolted to the pressure chamber base 11, and the pressure chamber wall 14 is fixed on the pressure chamber wall 12 through spacers. At the bottom, the sealed cavity formed between the two is a vacuum insulation cavity 43. Through vacuuming, the external environment and the heat exchange inside the equipment are isolated. The sealed cavity surrounded by the pressure chamber wall 14 and the pressure chamber door 20 is the surrounding Pressure chamber one 15 is provided with a number of circulating water channel...

Embodiment 2

[0067] The true triaxial testing system of the present invention can carry out following experimental research:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com