Integrated complete equipment for TLCP (thermotropic liquid crystal polymer) polymerization granulation

A complete set of equipment and equipment technology, applied in the field of polyarylate chip preparation equipment, can solve problems such as staying, and achieve the effects of improving quality, reducing labor intensity, and improving mechanized integrated production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

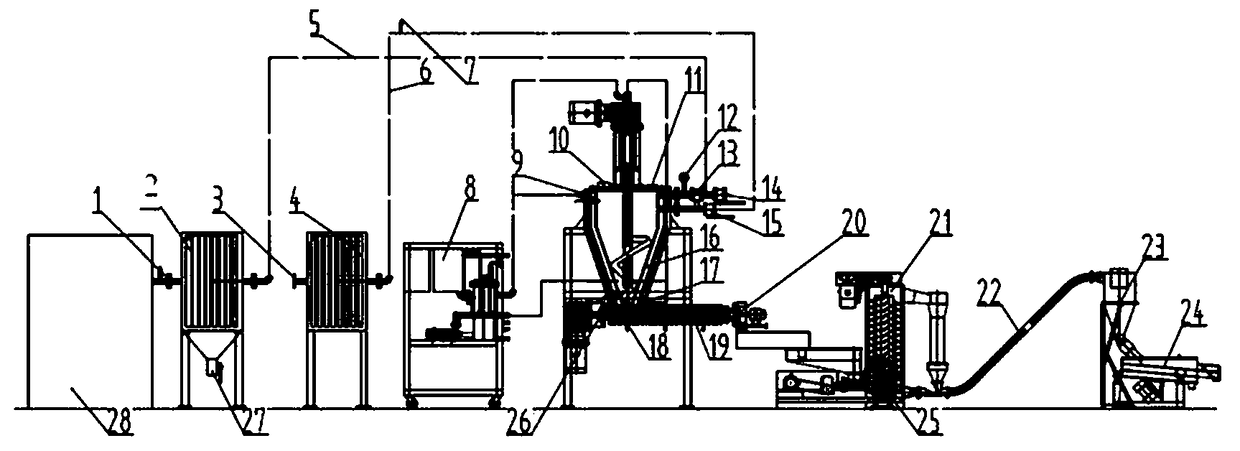

[0030] An integrated complete set of equipment for TLCP polymerization and granulation is provided, including a reaction kettle 16, a material extruder 19, a water ring hot-cut granulator 20, and an oil temperature machine 8. The reaction kettle 16 has a first feeding port 10 and a first discharge port, the material extruder 19 has a second feed port and a second discharge port, the first discharge port is connected to the second feed port by a slide valve 17, The gate valve 17 controls the connection or isolation between the first discharge port and the second feed port; the water ring hot cutting granulator 20 has a third feed port, a third discharge port, and the third The material inlet is connected to the second material outlet to receive the material extruded from the material extruder 19 and perform material cutting operation on the material. The reaction kettle 16, the material extruder 19, the water ring hot cutting granulator 20, and the oil temperature machine 8 in ...

Embodiment 2

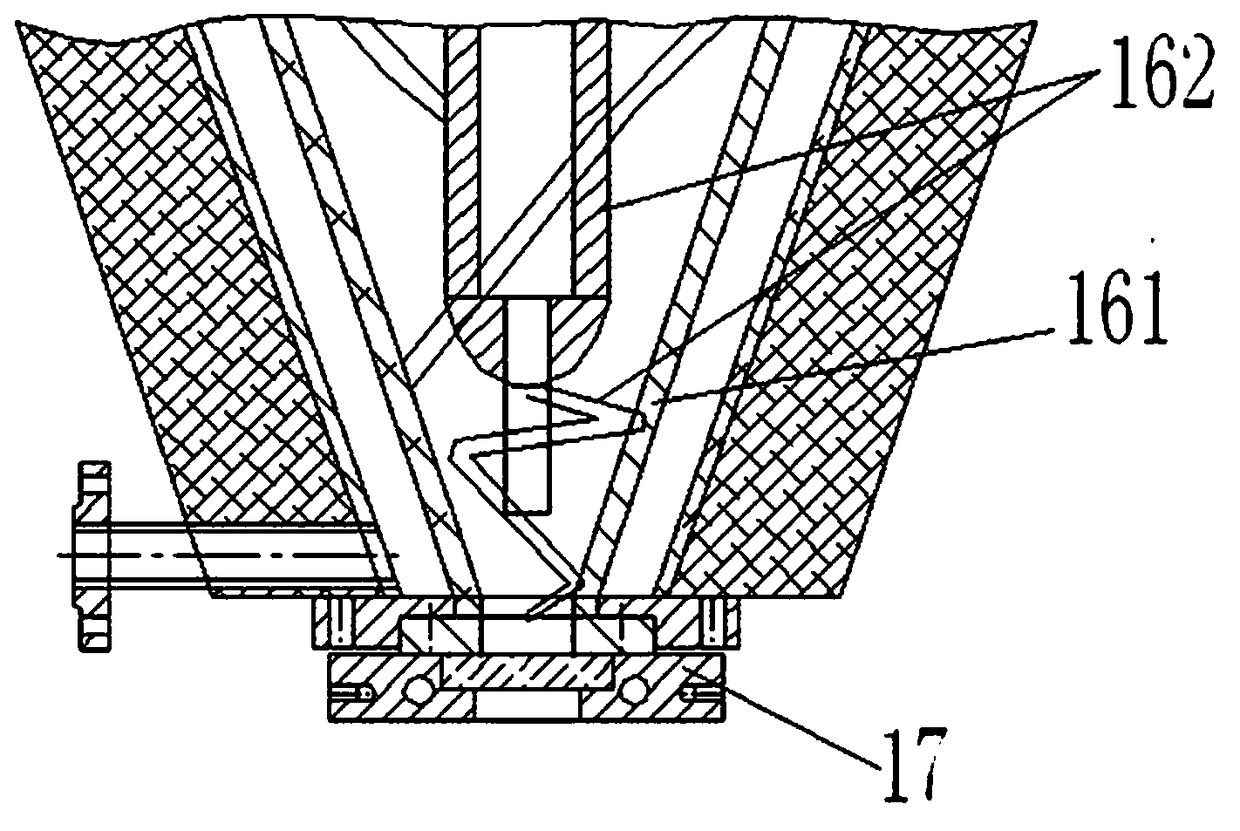

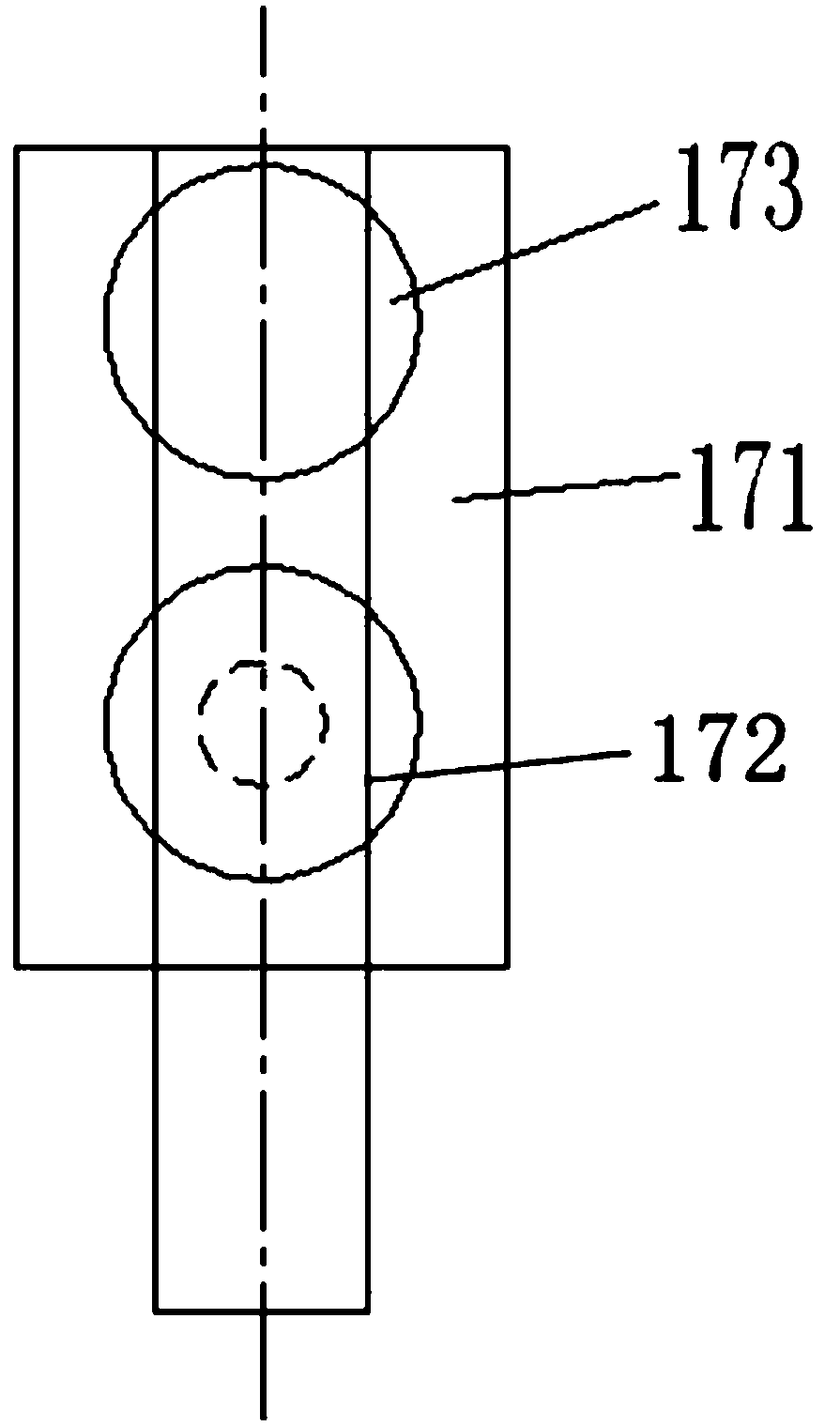

[0032] For further optimization of Example 1, since the raw material flowing out of the first discharge port is liquid, when it passes through the gate valve 17, the temperature at the gate valve 17 is much lower than that of the reaction kettle 16, at this moment, the time consumption of the liquid material at the gate valve 17 will be directly related to the fluidity of the liquid material in the follow-up device, therefore, as an implementation of the gate valve 17, preferably , the gate valve 17 is a plate-shaped structure, including a valve plate 171 connected to the cylinder drive, the valve plate 171 is provided with a through hole 173 and a blocking portion 172, the first outlet and the second Between the two feed ports, there is a flapper valve gap that cooperates with the valve plate 171, and the through hole portion 173 and the plugging portion 172 alternately cooperate with the flapper valve gap to realize closing and opening; the thickness of the valve plate 171 is...

Embodiment 3

[0035] For further optimization of Example 1, as another implementation of the gate valve 17, the gate valve 17 is a circular structure, including a flexible plate 170, a first winding roller 1720, a second winding roller 1721, a synchronous The belt 174, the first gear 1760 coaxially fixed to the end of the first roll 1720, the second gear 1761 coaxially fixed to the end of the second roll 1721, and the servo motor 178, the two ends of the flexible plate 170 are respectively rolled Attached to the first roll 1720 and the second roll 1721, the flexible plate is provided with a closed solid part and an open hollow part;

[0036] The synchronous belt 174 is tensioned and connected to the first gear 1760 and the second gear 1761, and the output shaft of the servo motor 178 is drivingly connected to the first gear 1760 or the second gear 1761;

[0037] Between the first discharge port and the second feed port, there is a gate valve gap that cooperates with the flexible plate 170, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com