Wireless detection system for papermaking machine dryer surface temperature

A surface temperature, wireless detection technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of increasing power consumption, affecting the speed of the paper machine, affecting the drying uniformity of the paper web, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

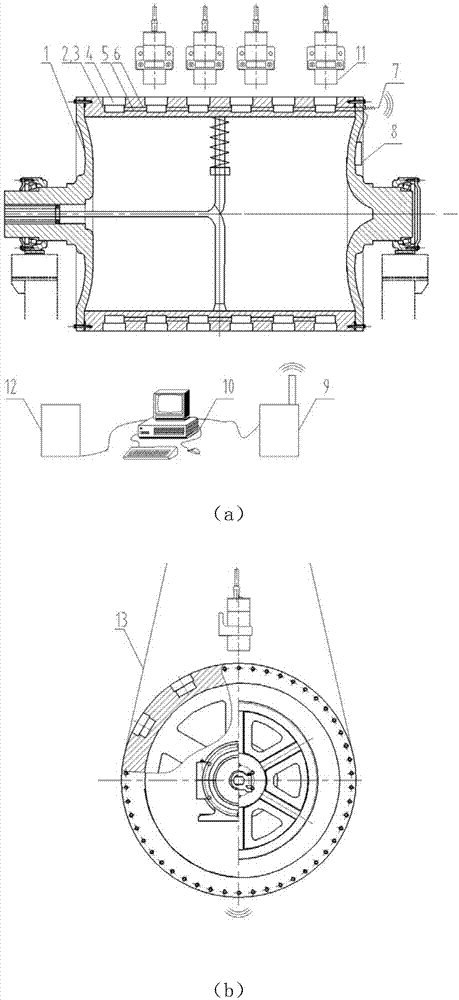

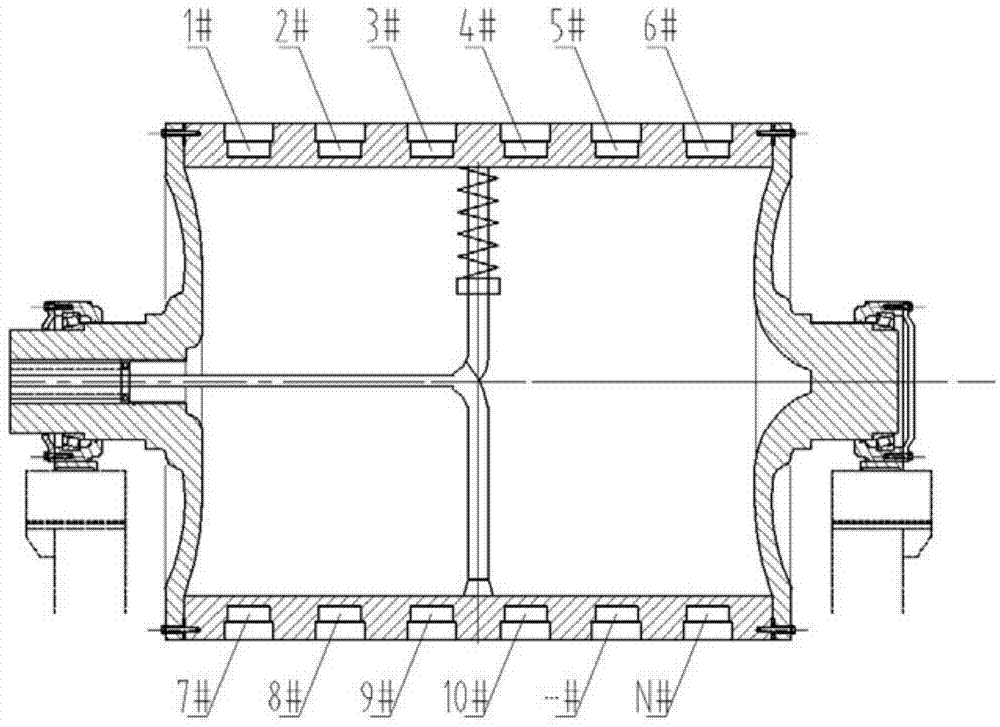

[0034] Such as figure 2 As shown, for a certain paper machine drying cylinder, there are numbered 1#, 2#, 3#, ..., N# wireless temperature sensors installed on the working wall, and a certain number can be obtained according to the temperature fed back by the wireless temperature sensor. The temperature distribution on the surface of the drying cylinder is used to analyze and evaluate the consistency of the temperature distribution of the drying cylinder. If the local temperature difference of the drying cylinder is too large, it reflects that the local heat transfer of the drying cylinder is uneven, and it needs to be repaired.

Embodiment 2

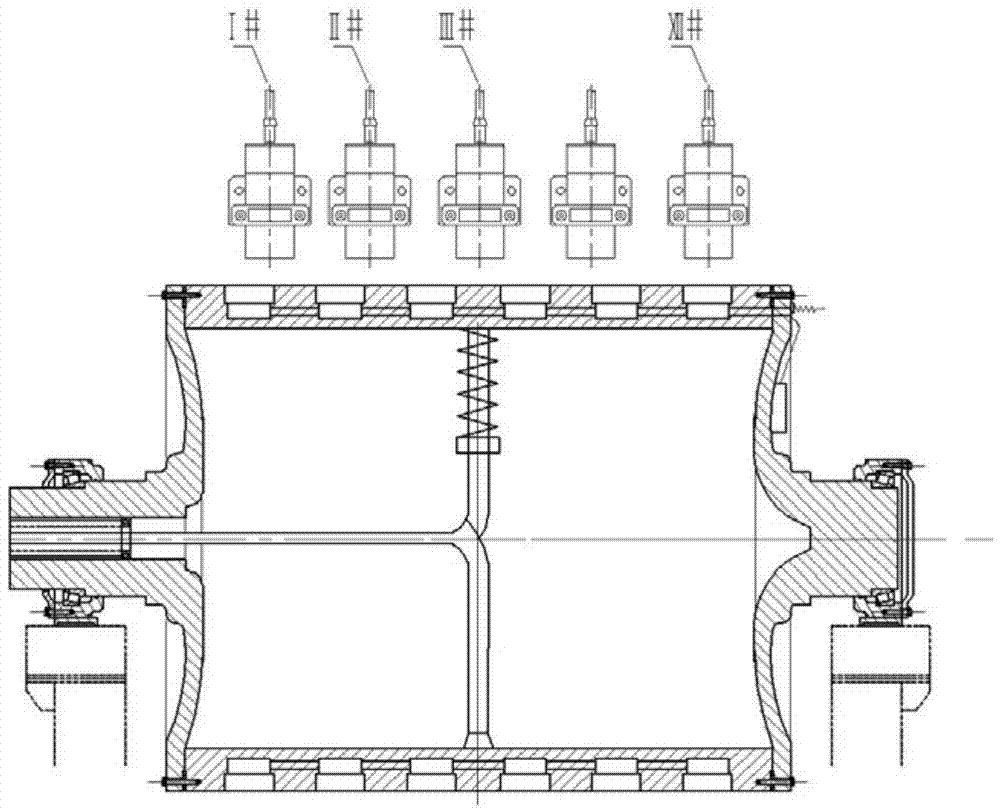

[0036] Such as image 3 As shown, for a certain paper machine drying cylinder, the blank area between the drying cylinder and the wire section or the paper web, there are respectively arranged numbers Ⅰ#, Ⅱ#, Ⅲ#, ..., Ⅺ# along the direction of the paper machine transmission axis The infrared temperature sensor can obtain the temperature distribution of a certain numbered dryer from the operation side to the transmission side according to the temperature fed back by the infrared temperature sensor. If the temperature difference from the operation side to the transmission side is too large, it means that the dryer may have accumulated water or It is a poor heat transfer problem and needs to be repaired.

Embodiment 3

[0038] Such as Figure 4 As shown, for a paper machine with multiple drying cylinders, especially a fourdrinier paper machine, there are more than one drying cylinders, and the corresponding drying cylinders are respectively numbered A#, B#, C#, ..., M#, each drying cylinder There are multiple wireless temperature sensors installed in the working wall, respectively numbered A1#, A2#, A3#,..., MN#, according to the temperature fed back by each wireless temperature sensor, the temperature of each drying cylinder along the direction of the paper machine can be obtained. Surface temperature distribution, average the temperature measured by all the temperature sensors installed in a certain drying cylinder, the average surface temperature of all drying cylinders along the direction of the paper machine can be obtained, if the average temperature of a certain drying cylinder is abnormal, it will be fed back to the control system Adjust or repair a certain section of dryer.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com