Cooling system with heat transfer enhancement effect and capable of effectively maintaining temperature uniformity of galvanic pile

A technology that strengthens heat transfer and cooling systems, applied in climate sustainability, circuits, fuel cells, etc., can solve problems such as uneven temperature distribution of stacks, easy leakage of coolant, poor cooling effect, etc., to ensure uniform temperature distribution performance, leakage prevention, and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

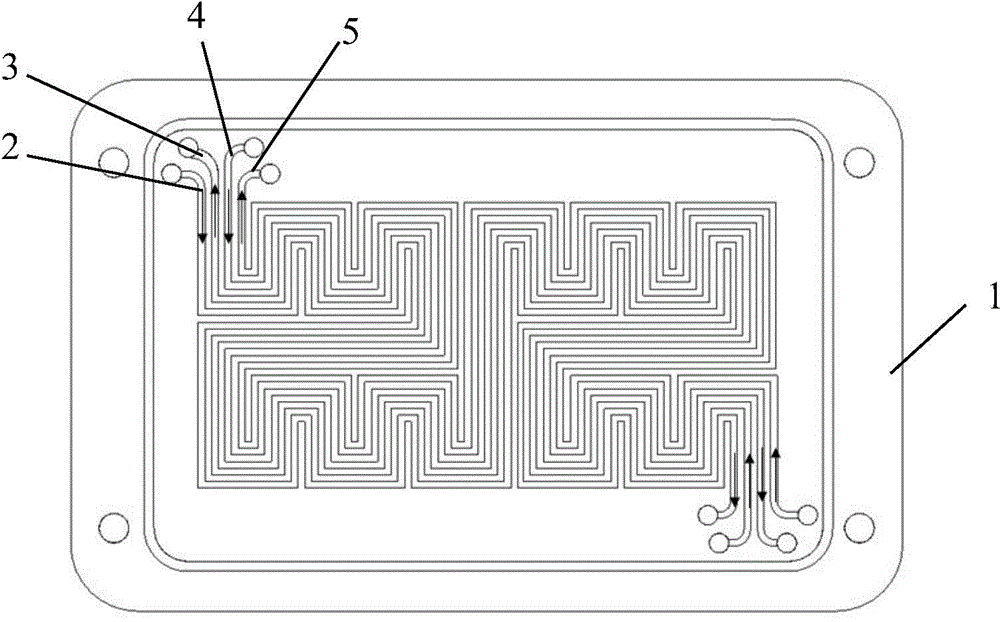

[0027] figure 1 It is one of the core components of the present invention. The cooling plate 1 adopts a four-channel structure, and the existing cooling channels mostly adopt structures such as straight channels and serpentine channels. figure 1 There are multiple continuous bending structures in the cooling channel, which can promote the coolant to generate secondary flow, vortex and other hydrodynamic phenomena in the flow channel. This flow phenomenon will help break the thermal boundary layer in the cooling channel and improve Strengthen the heat transfer factor and increase the heat transfer efficiency. In the adjacent cooling channels in the cooling plate, the cooling liquid flows in the opposite direction, figure 1 It has been marked that this arrangement helps to prevent hot and cold areas in the battery board and ensure the normal operation of the fuel cell.

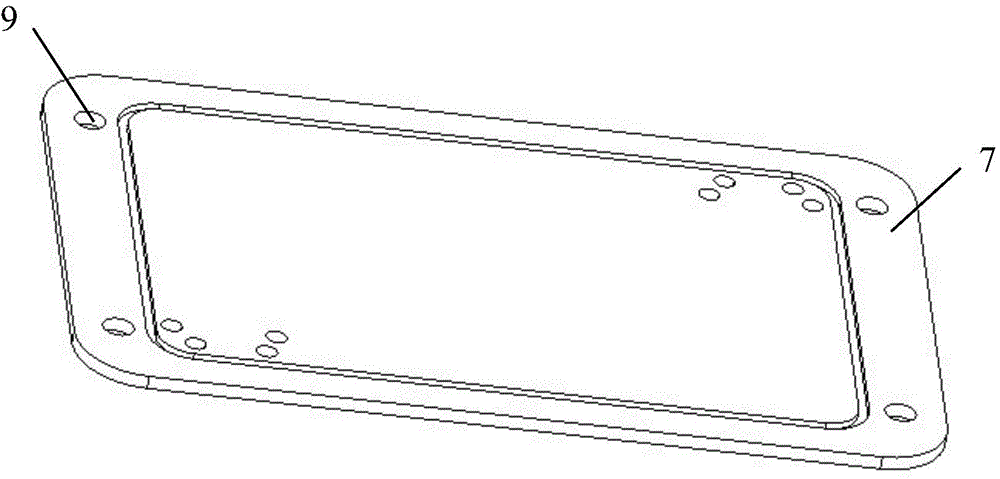

[0028] figure 1 1 slot in the middle cooling plate, figure 2 Medium rubber sealing ring 6, image 3 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com