LED constant-current driver with boosting function

A constant current driver and function technology, applied in the output power conversion device, the conversion of DC power input to DC power output, instruments, etc., can solve the problems of no boost, energy waste, and inability to use constant voltage power supply for power supply, etc. The effect of avoiding drive current, preventing battery life from shortening, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

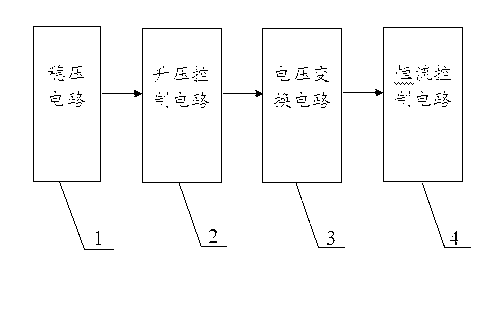

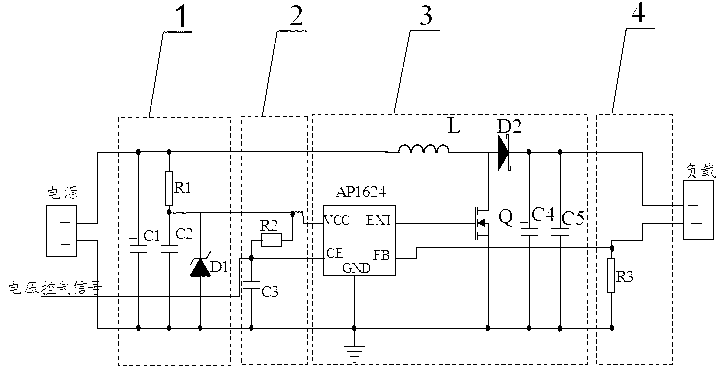

[0017] Such as figure 1 , 2 As shown, the LED constant current driver with boost function of the present invention includes a voltage stabilizing circuit 1 connected between the power supply and the load, a boost control circuit 2, a voltage conversion circuit 3 and a constant current control circuit 4, the voltage stabilizing The output end of the circuit is electrically connected to the input end of the boost control circuit, the output end of the boost control circuit is electrically connected to the input end of the voltage conversion circuit, and the output end of the voltage conversion circuit is electrically connected to the constant current control circuit.

[0018] Such as figure 2 As shown, the output terminal of the chip AP1624 is the EXT terminal, the input terminal is the VCC terminal, the control terminal is the CE terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com