Frame and electric vehicle thereof

An electric vehicle and frame technology, applied in the field of electric vehicles, can solve the problems of poor structural stability, lack of shock absorption, and short service life, and achieve the effects of low cost, easy direct assembly, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

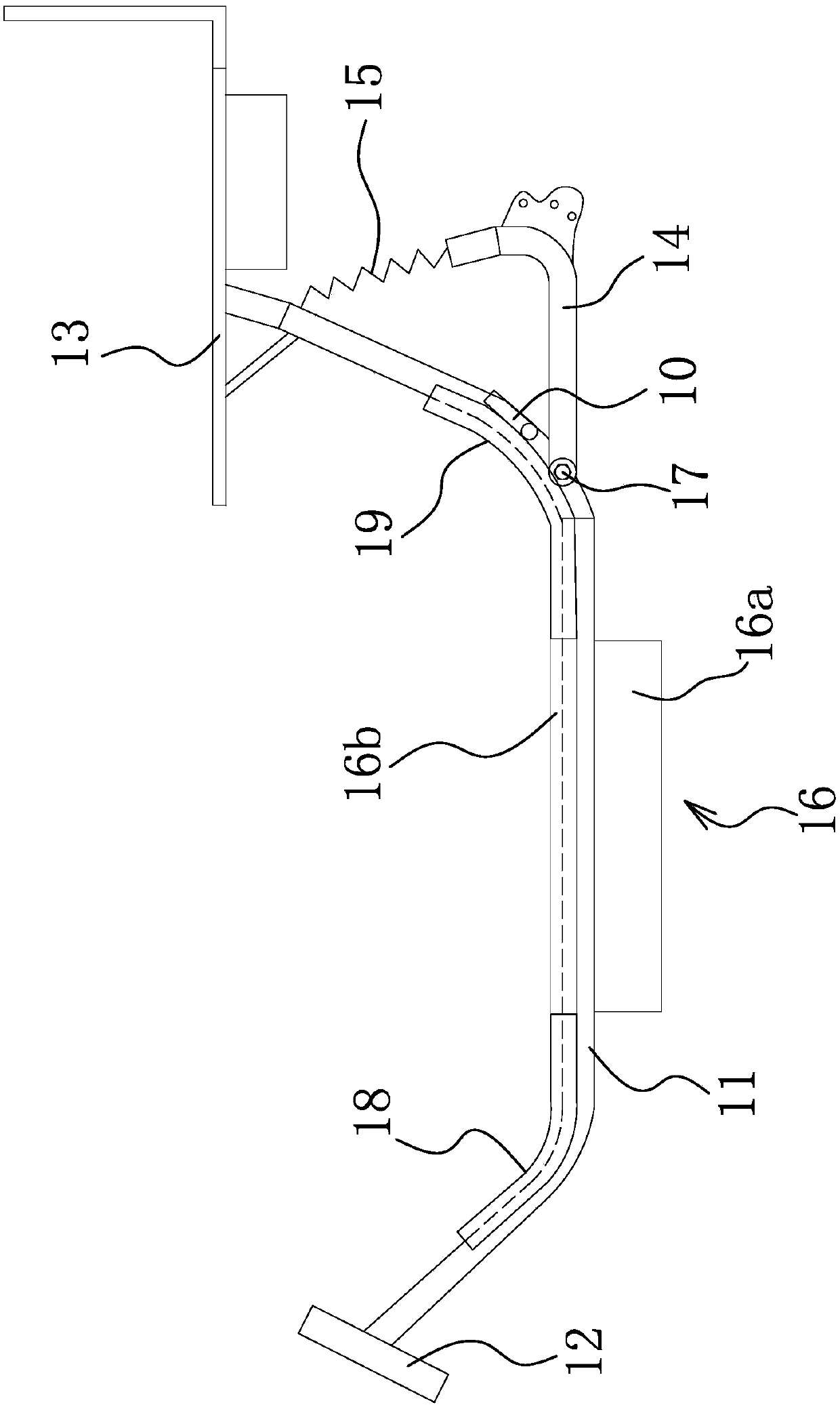

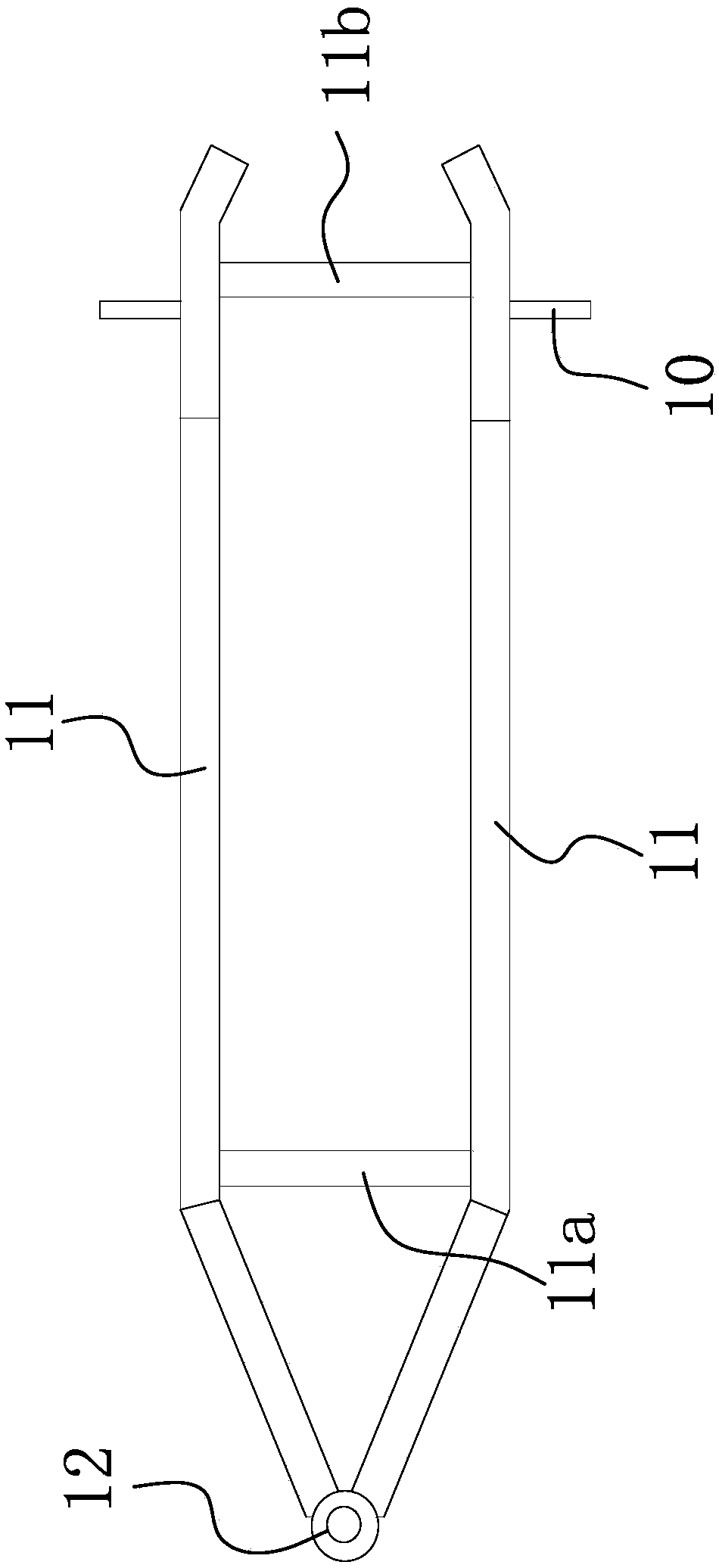

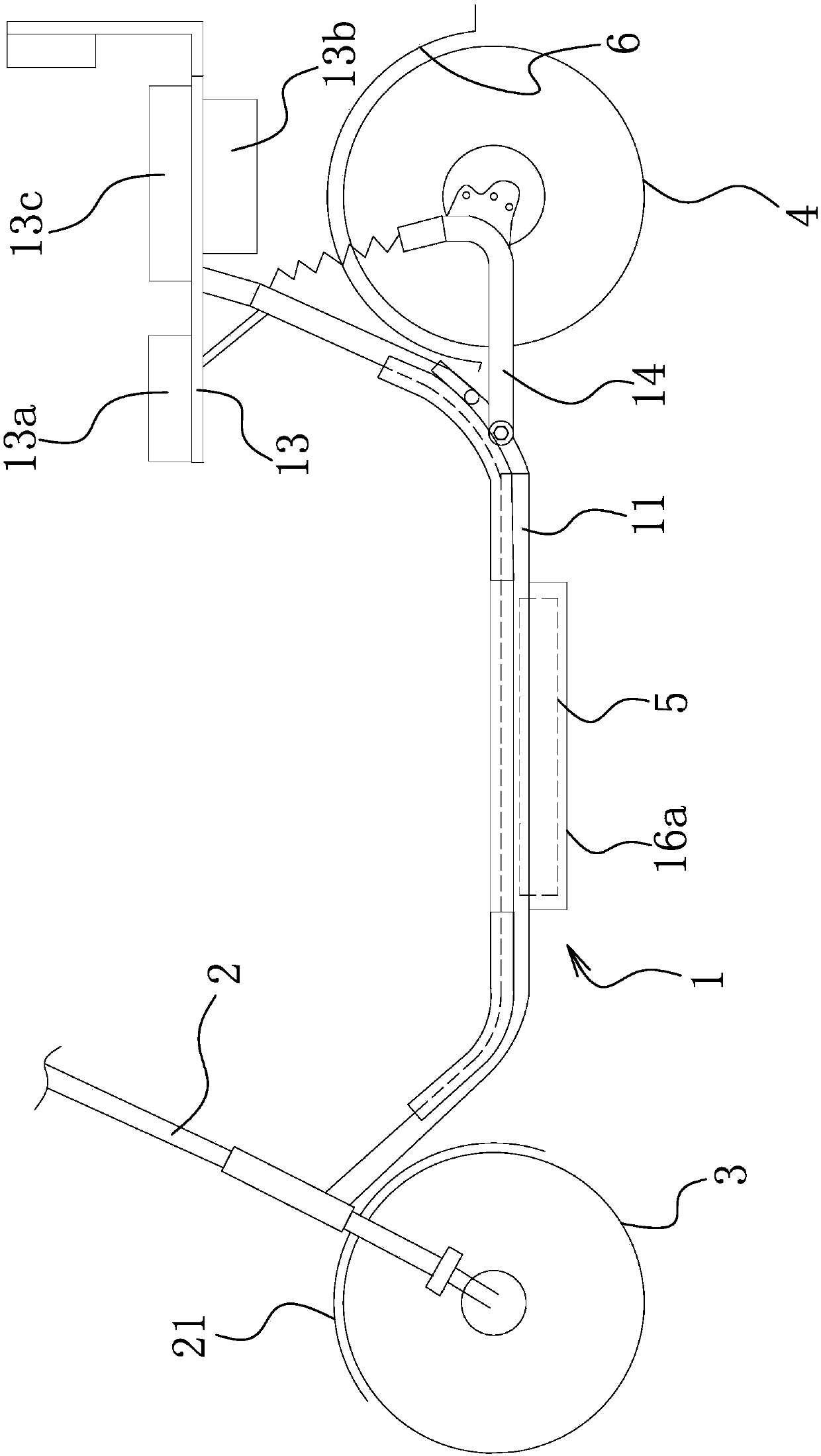

[0035] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0036] Such as Figure 1-3 As shown, the vehicle frame includes two symmetrically arranged vehicle frame main girders 11, and the vehicle frame main girders 11 are directly cut and made from pipe materials.

[0037] Its outer diameter of two vehicle frame girders 11 is equal to pipe wall wall thickness.

[0038] By directly cutting the pipe, it not only improves the production efficiency, but also reduces the manufacturing cost.

[0039] In addition, the pipe material is a metal pipe material, which is convenient for subsequent welding processing.

[0040] The front ends of the two frame girders 11 are bent upwards and converged to be connected to the front insertion pipe 12 . That is, the front ends of the two frame main beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com