Manufacturing and test method of rock compression shearing test specimen containing intermittent joints at high temperature

A test method and rock technology, applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve problems such as difficult to carry out, shear damage, and inability to perform shear tests of intermittent joints, etc. To achieve the effect of enriching functions and improving cost performance

Pending Publication Date: 2018-04-06

CHENGDU UNIVERSITY OF TECHNOLOGY

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, due to the limitation of test instruments, it is difficult to carry out experiments to explore the influence of temperature on the properties of intermittent joints.

In the direct shear test and triaxial shear test of conventional rocks, the disadvantages lie in 1) the conventional direct shear test cannot conduct CT scanning and acoustic emission (AE) research on the shearing process due to the limitation of supporting equipment due to the cube shape of the sample , and the cubic sample cannot be placed in the temperature and pressure chamber for direct shear test under high temperature and high pressure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

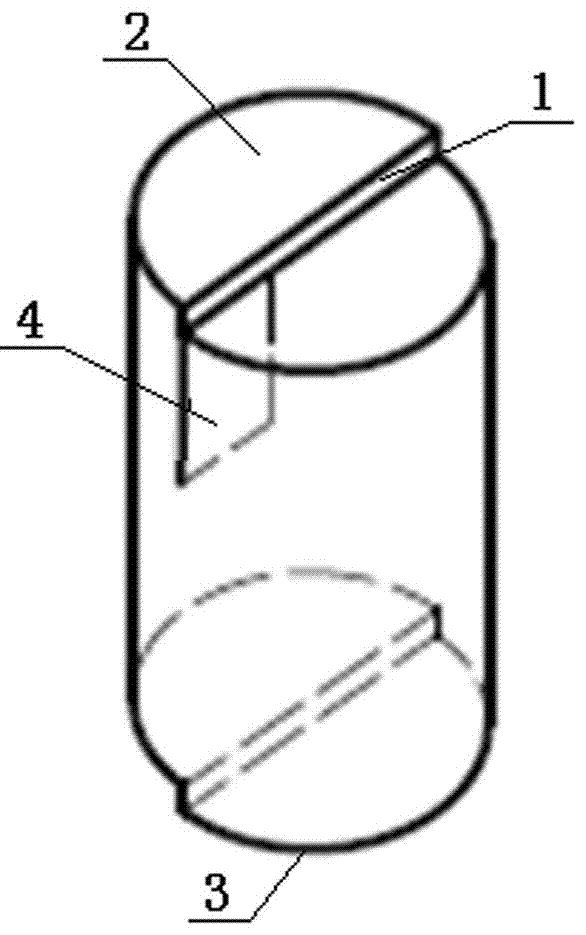

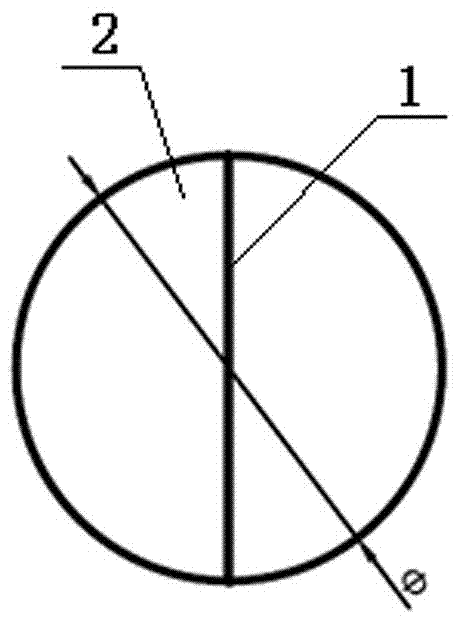

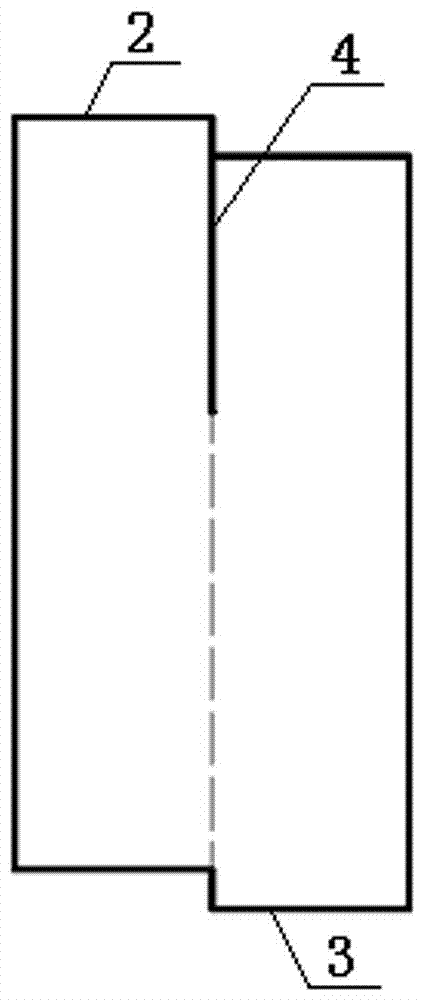

The method for making and testing rock compressive shear samples with discontinuous joints at high temperature in the present invention includes: 1) making rock compressive shear samples with discontinuous joints; 2) using rock compressive shearing samples with discontinuous joints The sample is tested for shear strength: a) Use the rock high-temperature triaxial compression test equipment to directly load the sample, carry out the rock compression test with discontinuous joints, and measure the shear strength with discontinuous joints; b) Use the rock high temperature The triaxial compression test equipment conducts the joint shear test under high temperature and high pressure conditions in the temperature and pressure chamber and the acoustic emission AE and CT scanning research during the test process: C) The shear plane of the rock compression shear sample with continuous joints is 10℃~ Testing of shear strength indicators (cohesion and internal friction angle) at 200°C. The invention can carry out acoustic emission (AE) test during sample compression and CT scanning test in compression process, has the advantages of exploring the effect of temperature and pressure conditions on joint properties, and makes up for the deficiencies of traditional rock samples.

Description

technical field [0001] The invention relates to a model making method capable of carrying out compression tests and shear tests containing intermittent joints under high temperature and high pressure conditions, and a test method based on the sample. The rock sample can be subjected to compression tests under various temperature and pressure conditions provided by the temperature and pressure chamber, as well as the shear strength test of the fixed shear surface of the rock sample; intermittent joints can be made at the position of the shear surface for use in Investigate the influence of temperature and pressure conditions on joint properties. Background technique [0002] With the rapid development of national infrastructure and the deepening of the western development, some new rock mass engineering problems have emerged in engineering construction. The thermodynamic properties of rock mass in deep tunnels is one of the outstanding problems. This is the classical rock...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/24

CPCG01N3/24G01N2203/0256

Inventor 吉锋何双李任杰

Owner CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com