Method and device for measuring interfacial shearing strength under the connection of disc and flat plate

A technology of interface shear strength and elastic contact, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of measurement error and low measurement accuracy, and achieve high measurement accuracy, simple device structure, manufacturing cost and use cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

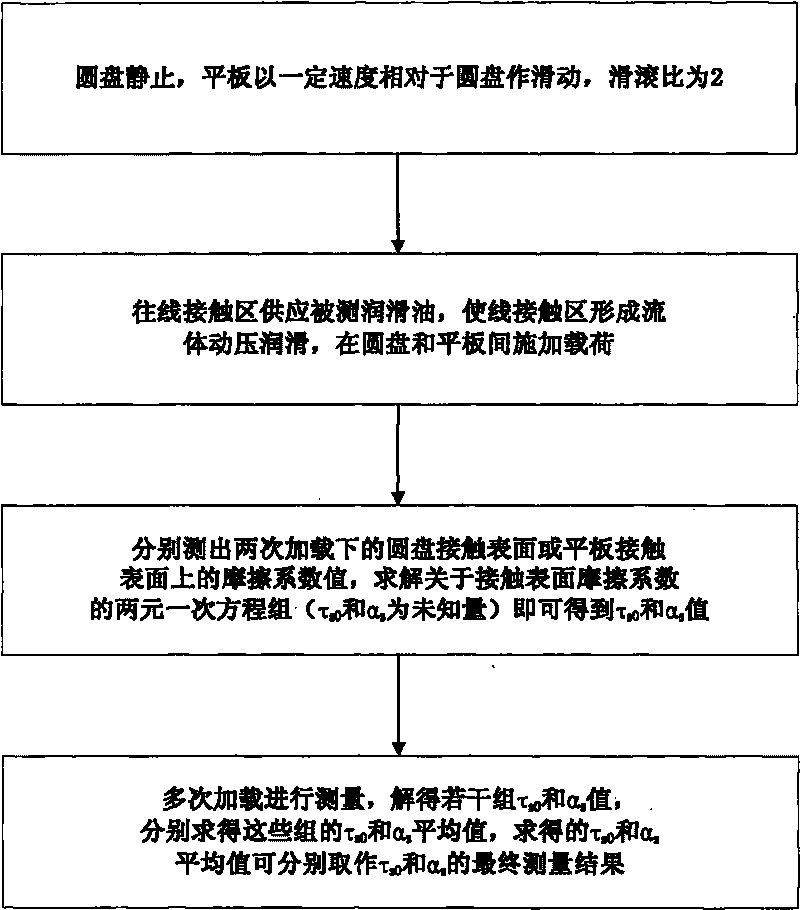

Method used

Image

Examples

Embodiment

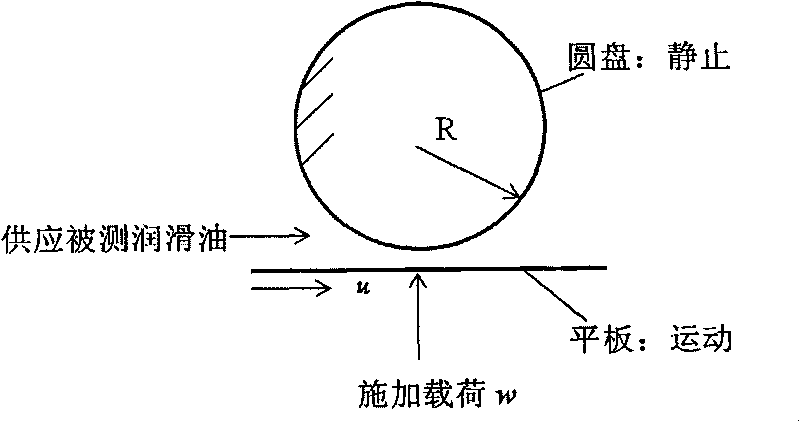

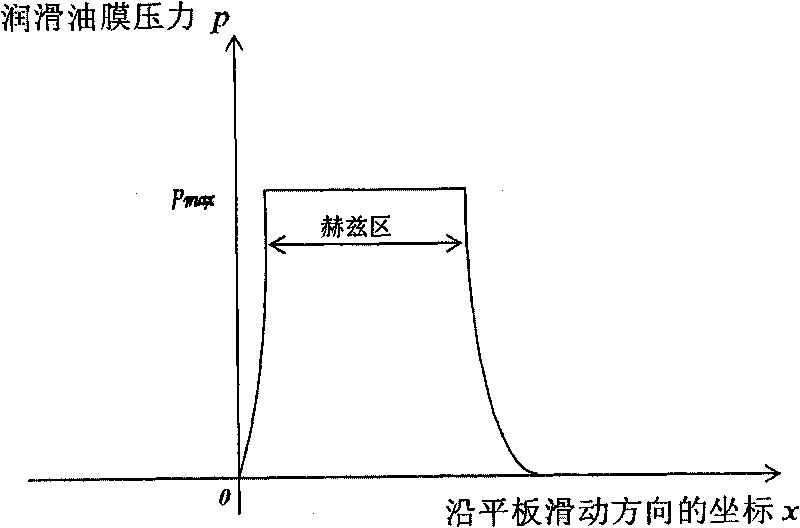

[0080] Both the disk and the plate are made of No. 45 steel, and the contact surfaces are all quenched, and the surface hardness reaches HRC50-53, HRD≈2.0GPa. The contact surfaces of the disk and the plate are finely ground, and the surface roughness is R a The values are all 0.1 μm. The integrated Young's modulus of elasticity of the contact surface of the disc and the flat plate is E'=209GPa. The lubricating oil used is paraffin oil LVI260 (international brand), the radius of the disc is 20mm, the thickness of the disc (axial) h=15mm, the width of the flat plate along the axial direction of the disc is 25mm, and the flat and disc along the axial direction of the disc The contact wire length is 15mm. The sliding speed of the plate relative to the disc is u=4.0m / s, and the dimensionless rolling speed is uη a / (2E'R)=1.91E-11.

[0081] 1. When the load applied between the disk and the plate is w 1 =3.0E+05N / m, that is, the dimensionless load applied between the disk and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com