Unfolding method for complex flange of frame rib sheet metal part

A sheet metal part and frame rib technology, which is applied in the field of complex flanging and unfolding of frame rib sheet metal parts, can solve the problems of high bending complexity, long cycle and large allowance of frame rib sheet metal parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

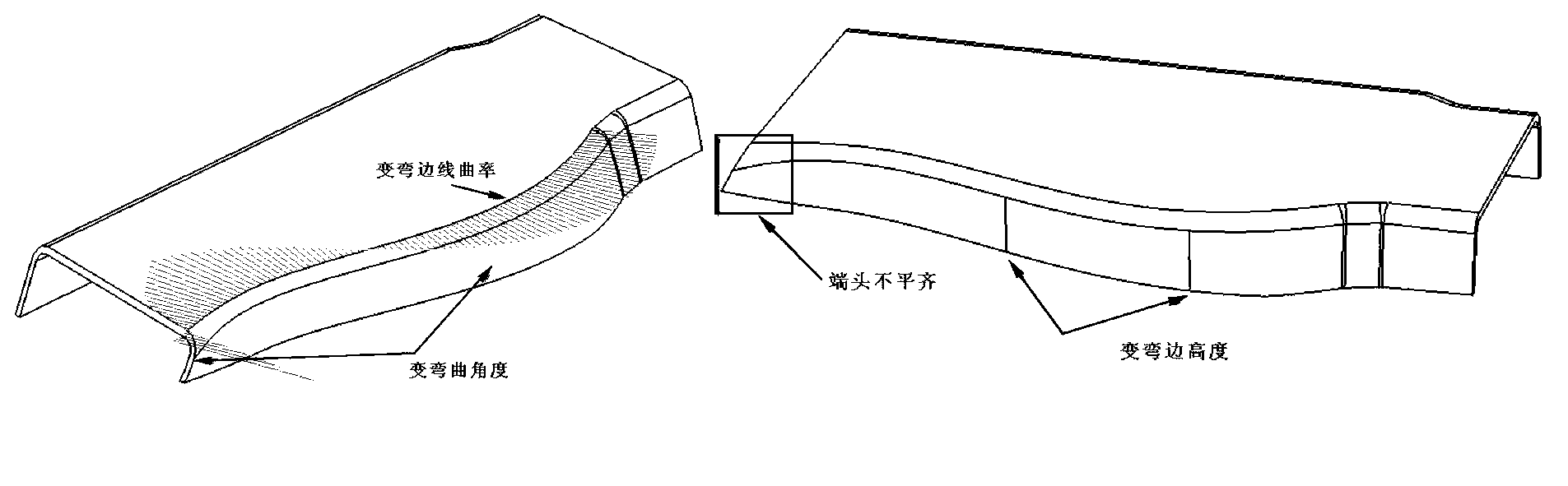

[0031] by figure 1 Take the complex bending of the aircraft frame rib sheet metal parts shown as an example. The bending has the characteristics of variable bending line curvature, variable bending angle, variable bending height, and uneven boundaries. Combined with the accompanying drawings, the specific implementation process of the complex flange expansion method for aircraft frame rib sheet metal parts is described as follows.

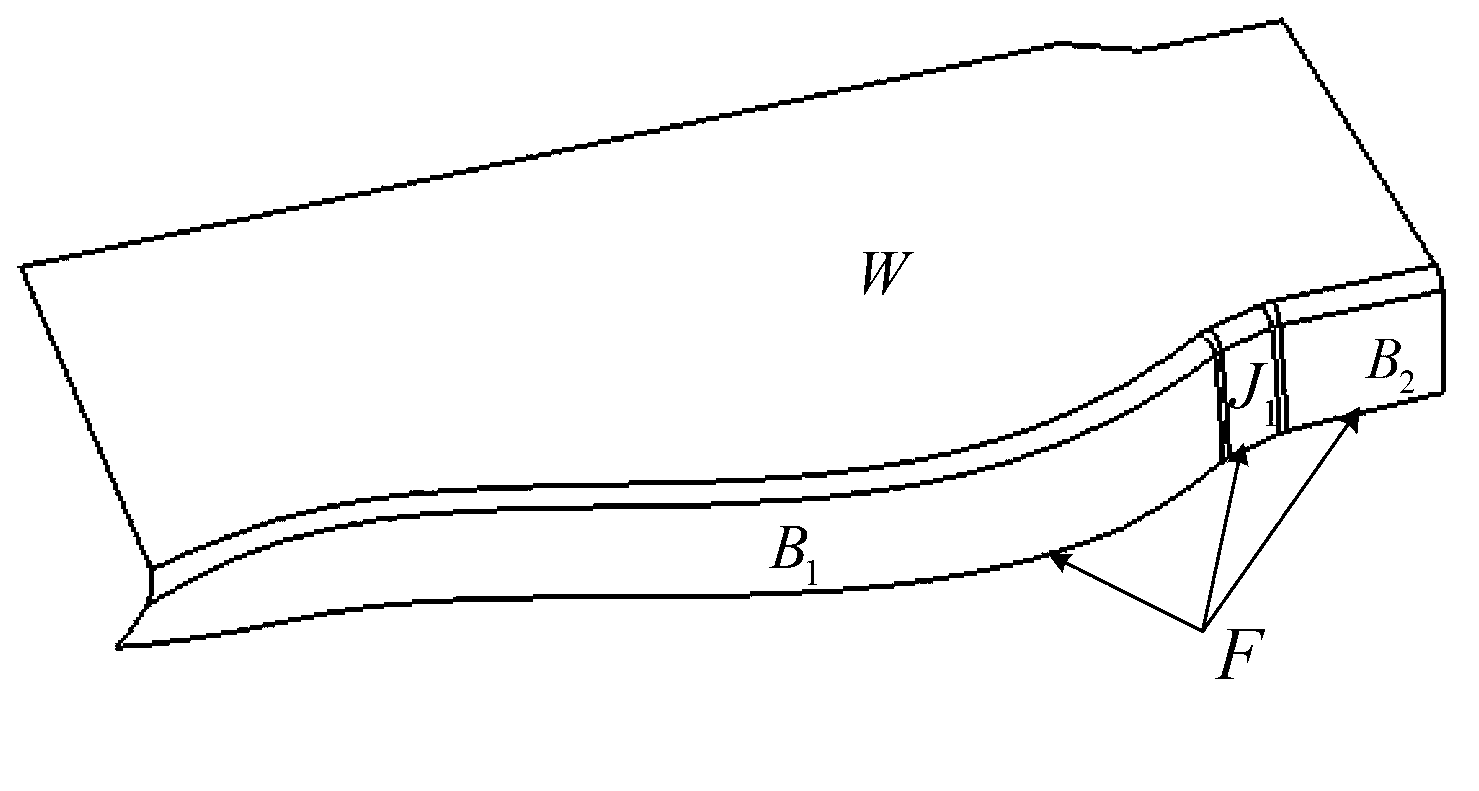

[0032] 1. The material thickness of this frame rib part is δ=2mm, extract the inner surface F of the flange adjacent to the inner surface W of the web, and F consists of two bending areas B 1 , B 2 with 1 subsidence zone J 1 composition (such as figure 2 shown).

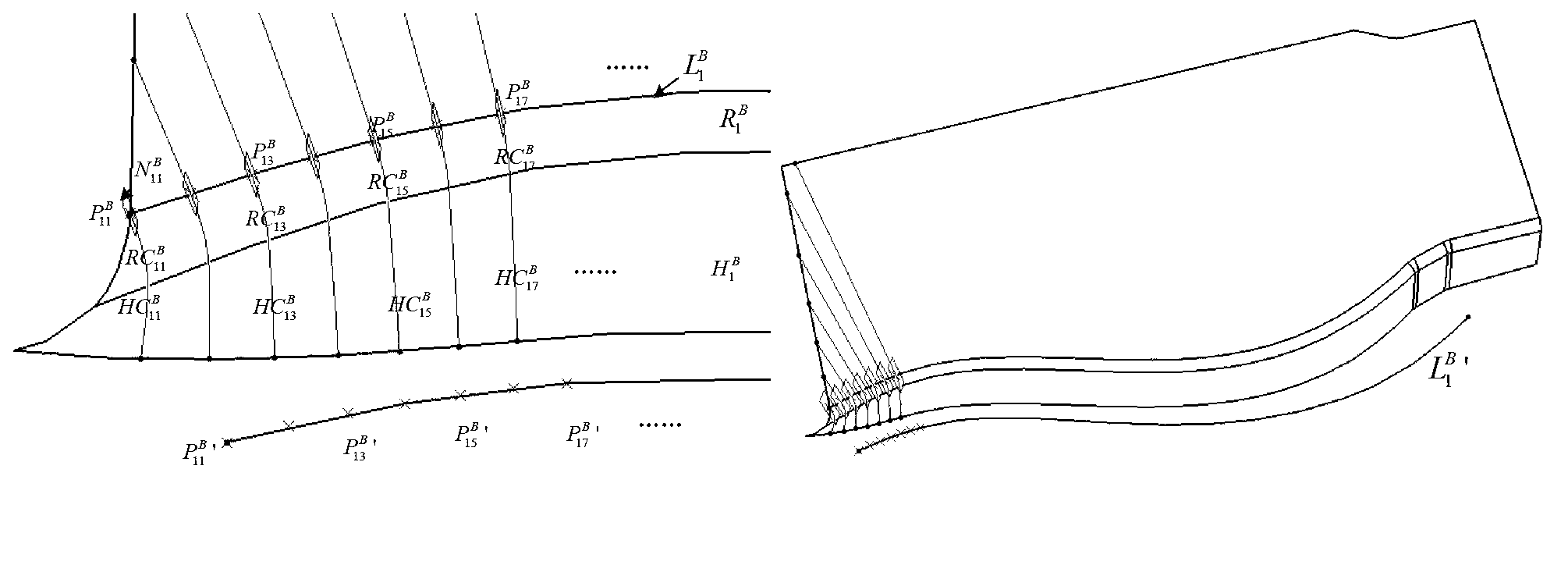

[0033] 2. Bending area B 1 The transition line with the web surface W is length Will B 1 Divide into fillets and flange face Carry out discrete segmentation, expansion value calculation, and expansion point fitting respectively (such as image 3 shown), and end treatment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com