Rock mass drilling and shearing elastic modulus instrument

A technology of elastic modulus and rock mass, which is applied in the direction of testing material strength by applying stable shear force and testing material strength by applying stable tension/pressure, which can solve the problem of single function and achieve good economic benefits and save energy. Effects of experimental funding, macroeconomics, and socioeconomic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

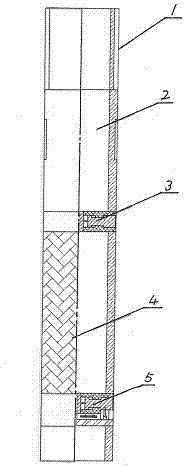

[0026] Depend on Figure 1 to Figure 5 As shown, a rock mass drilling shear elastic modulus instrument is mainly composed of a plug rod port 1, a sleeve rod 2, an upper disc cutter 3, a rubber bag 4 and a lower disc cutter 5, wherein: the overall structure is a long cylinder; A rubber bag 4 for applying normal stress is arranged between the upper disc cutter 3 and the lower disc cutter 5 .

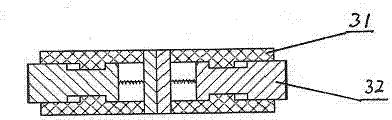

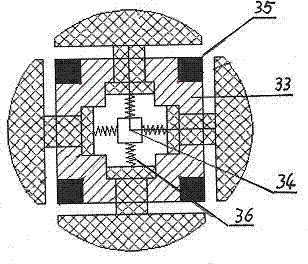

[0027] The upper disc cutter 3 is composed of an upper disc cutter cover plate 31, a piston disc cutter 32, a hydraulic housing 33, a central column 34, a matching square column 35 and a powerful spring 36, and four matching square columns 35 are used to fix the upper disc cutter 3 on the rock. The position on the body drilling shear elastometer, the upper disc cutter cover plate 31 is fixed on the hydraulic housing 33 to ensure that the four piston disc cutters 32 can protrude freely without being blocked by cuttings, and in addition, it is fixed on the center column The vigorous spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com