Multi-functional vibration device

A vibrating device and multi-functional technology, which is applied in the field of multi-functional vibrating devices, can solve the problems of time-consuming, multiple devices, and increased costs, and achieve the effects of improving service life, facilitating angle switching, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

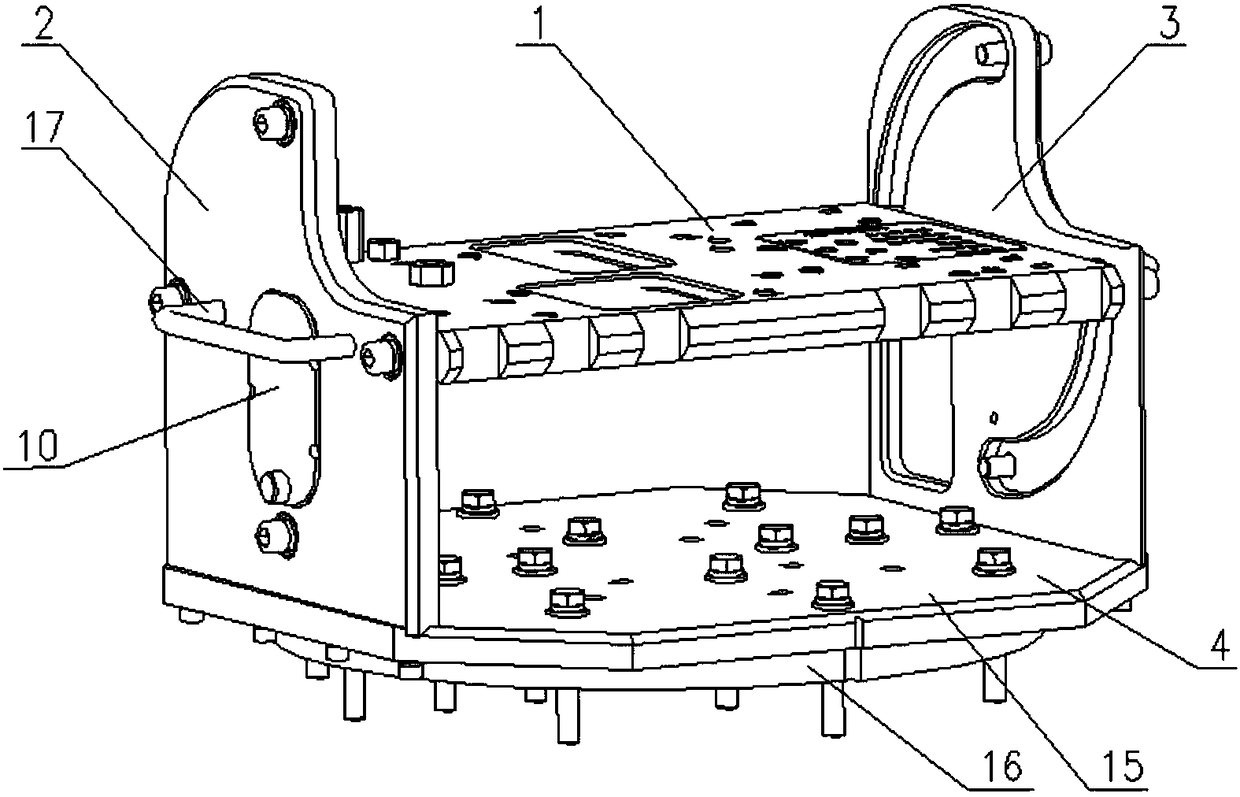

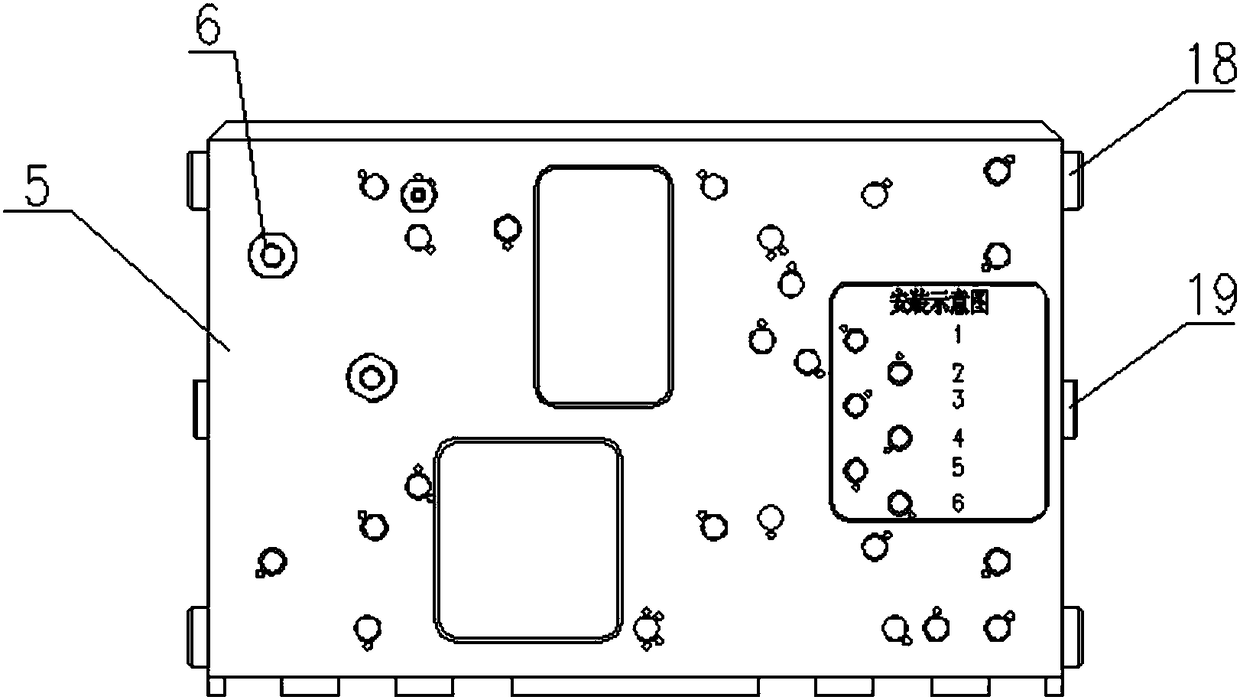

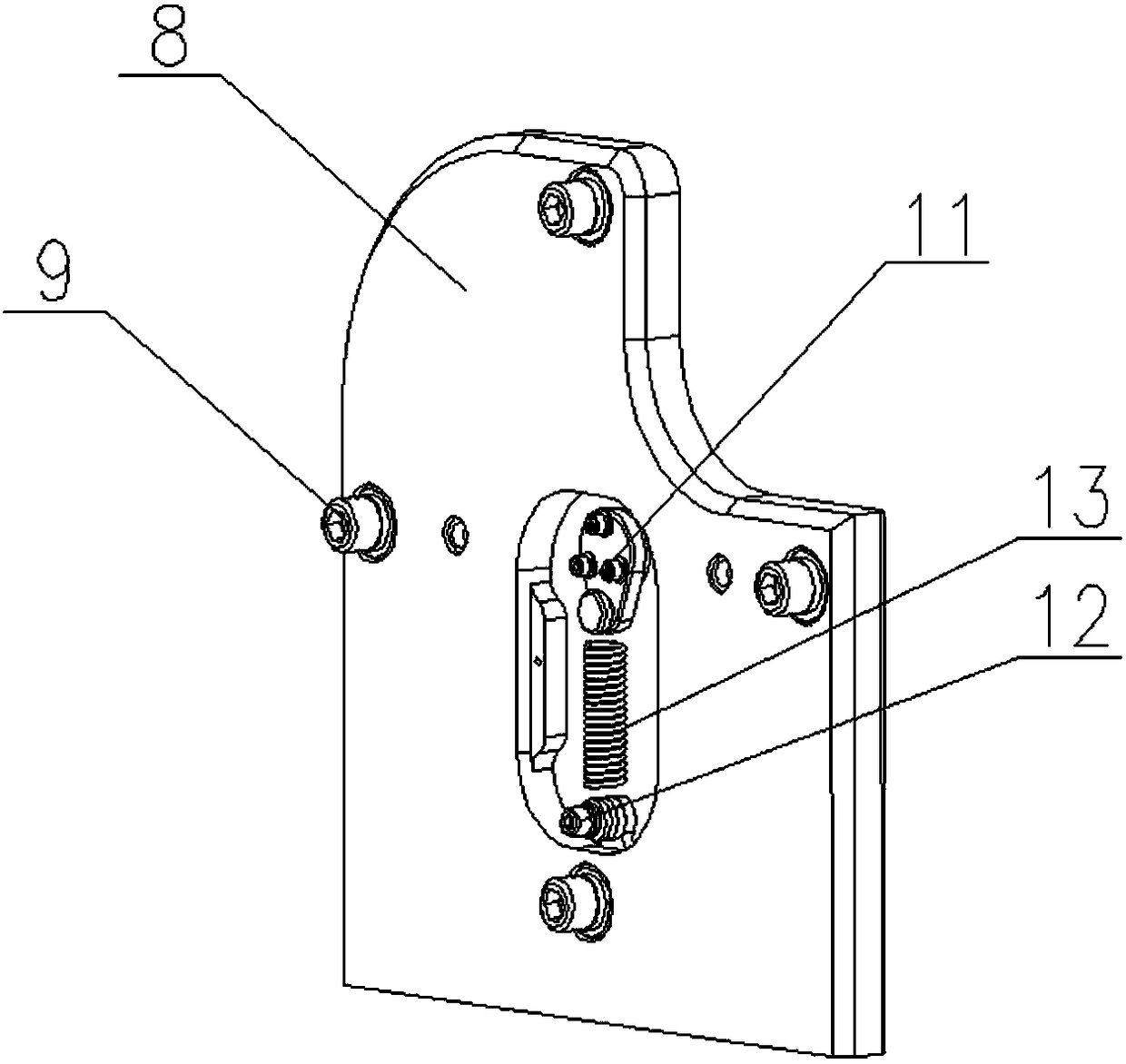

[0025] Such as Figure 1 to Figure 4 As shown, the multifunctional vibrating device provided by the present invention includes: left and right vertically arranged rotating frame assemblies 2, a mounting plate assembly 1 arranged horizontally between the rotating frame assemblies 2 and a 2 The test bench interface assembly 4 at the bottom, the middle of the two ends of the mounting plate assembly 1 connected to the rotating frame assembly 2 are respectively provided with a rotating shaft 19 and the ends are respectively provided with a limit boss 18, and the limit boss 18 and The rotating shaft 19 is made of the following materials by mass percentage: C: 0.7%; Si: 0.3%; Mn: 1.2%; Cr: 1.5%; B: 0.3%; P: 0.02%; S: 0.02% ; Ti: 0.04%; the balance is Fe; the rotating frame assembly 2 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com