Smelting equipment for ingots

A smelting equipment and ingot casting technology, applied in the field of ingot smelting equipment, can solve the problems of scrap ingot material, many defects, sputtering target defects, etc., and achieve the effects of reducing residual gas, reducing solubility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It can be seen from the background art that the ingots obtained by existing equipment often have the problem of many defects. Now combined with a kind of ingot smelting equipment to analyze the reasons for its defects:

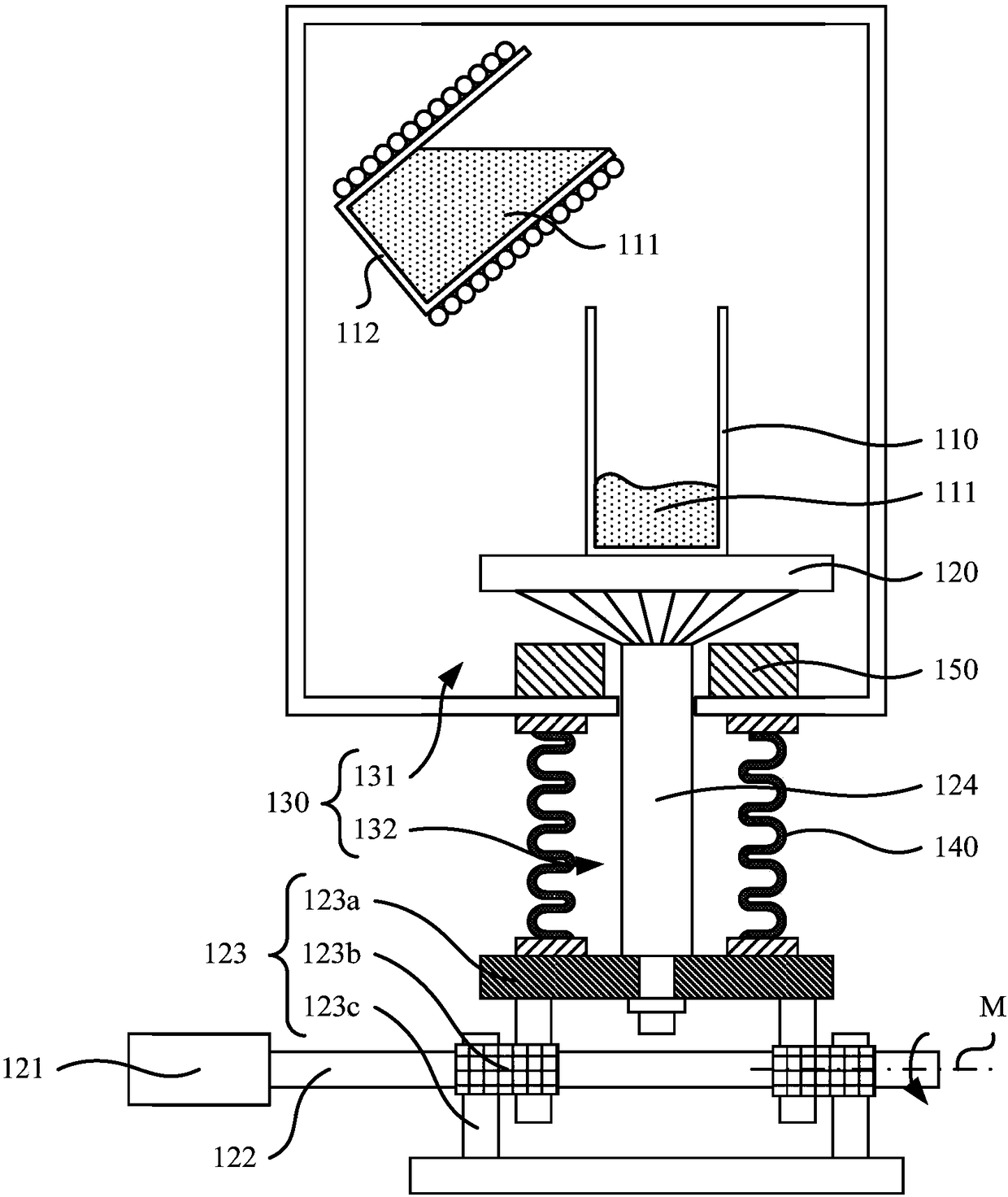

[0038] Vacuum induction melting furnace (Vacuum Induction Melter) is a vacuum smelting complete set of equipment that uses the principle of medium frequency induction heating to melt metal under vacuum conditions. This equipment can be used to extract high-purity metals and alloys.

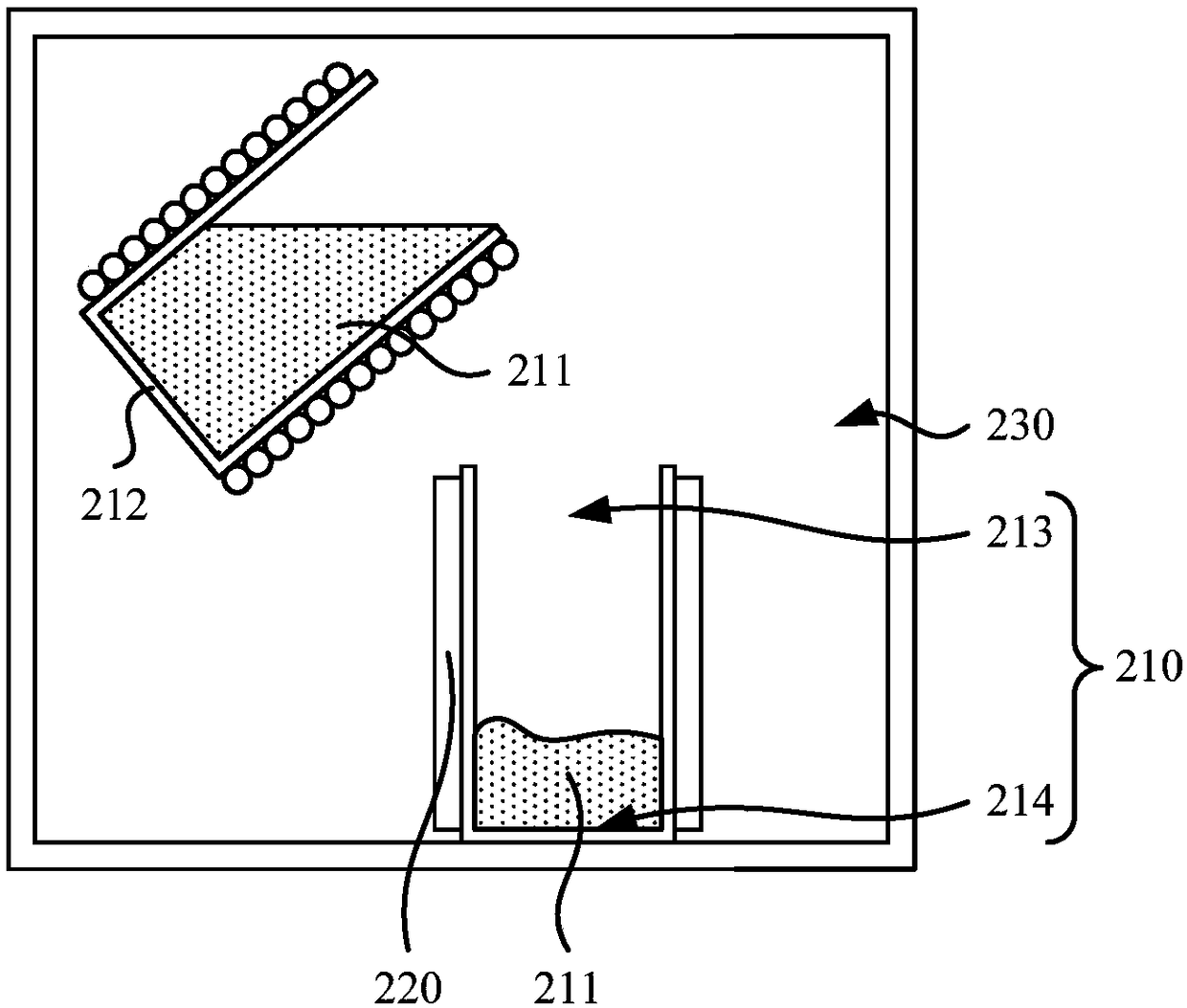

[0039] The existing vacuum induction melting furnace generally includes an induction coil, a graphite crucible and a graphite mold. The graphite mold is set on the base in the vacuum induction furnace. The copper raw material is heated and melted in the graphite crucible to form molten metal; the molten metal is poured into the graphite mold to be cooled to form an ingot.

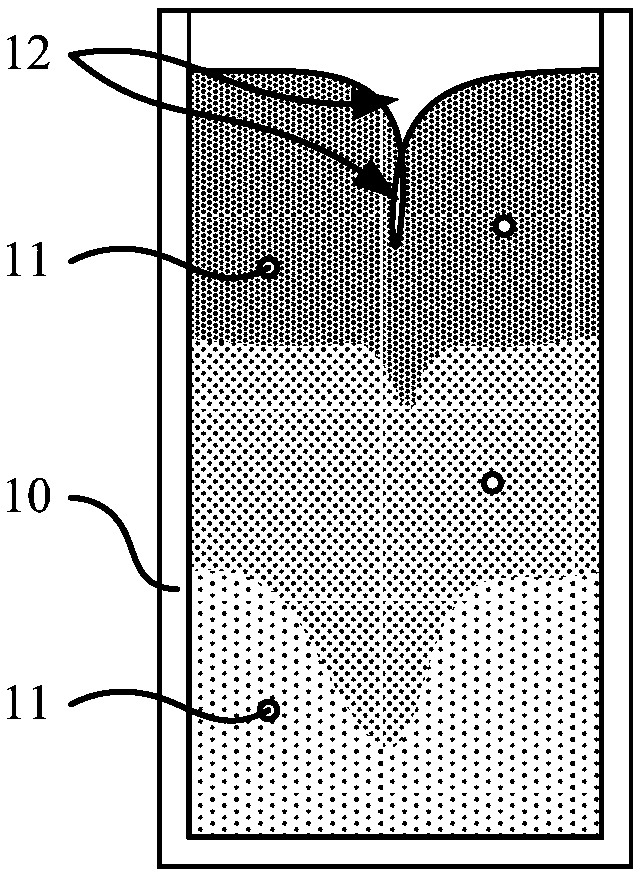

[0040] refer to figure 1 , shows a schematic cross-sectional structure of an ingot obtained by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com