Telescopic lining structure testing device for testing characteristic curve of tunnel surrounding rock

A characteristic curve and structural test technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of easy damage, waste of capital, man-hours, low efficiency, etc., achieve high accuracy and reliability, and save materials and test cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

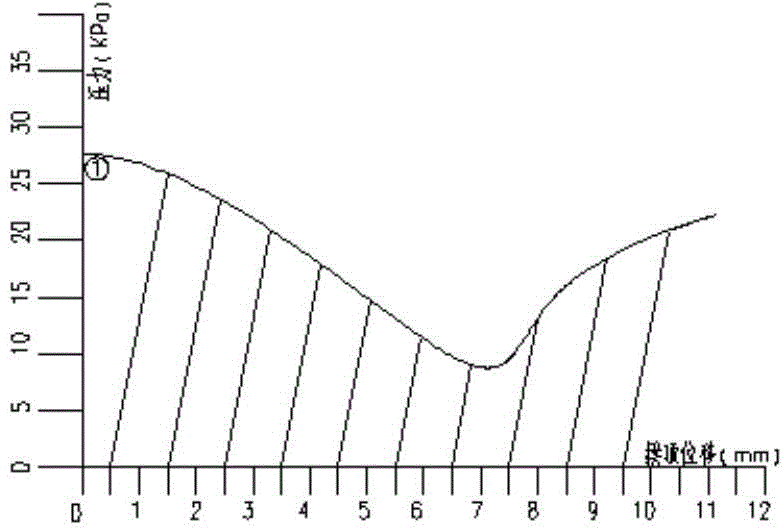

[0017] Such as figure 1 Shown is the resistance-displacement characteristic curve of the surrounding rock support measured by the test.

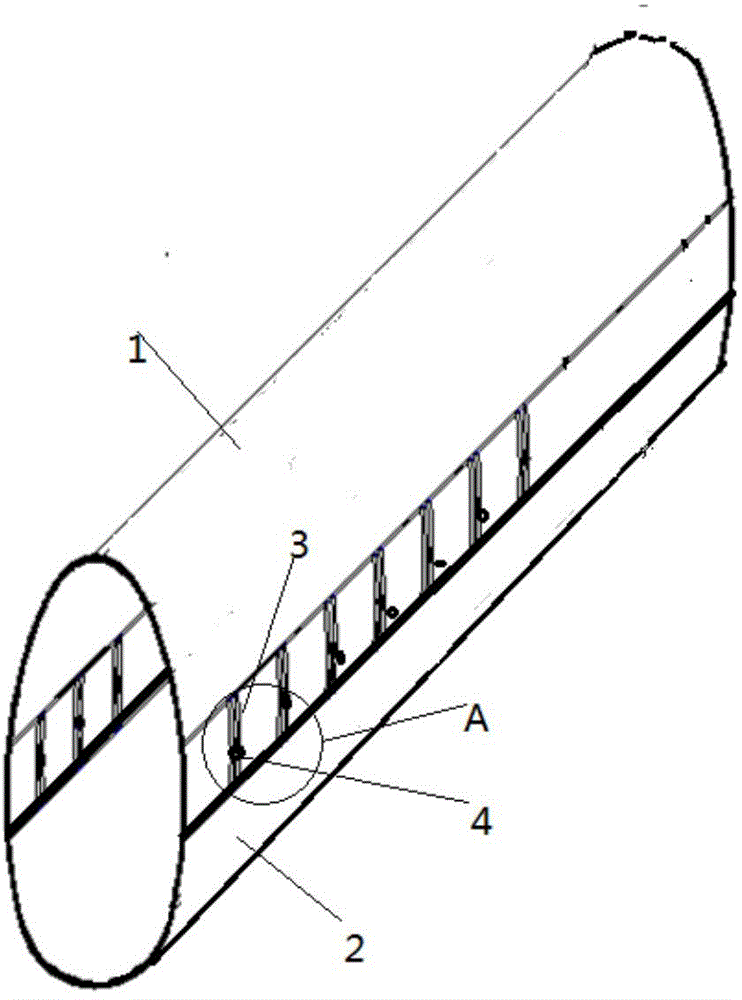

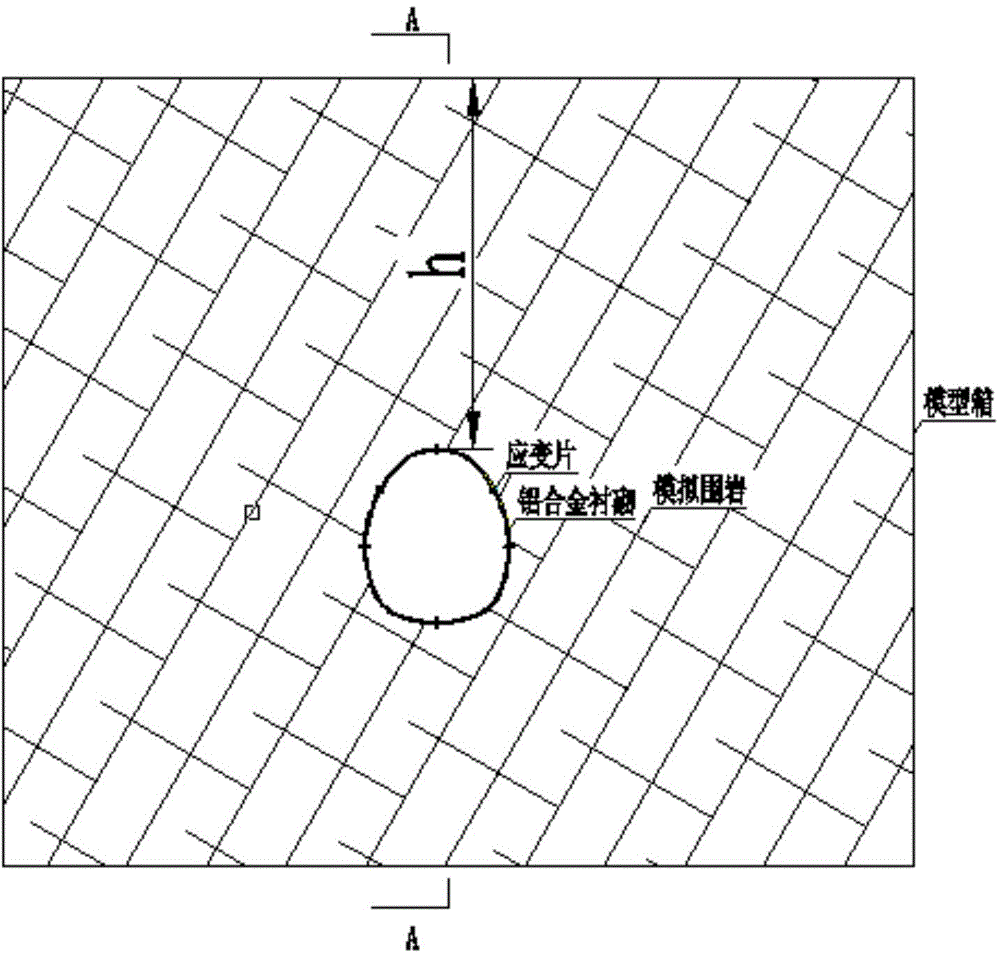

[0018] The appearance of this device (aluminum alloy tunnel lining) is as follows: figure 2 , combined with Figure 5 It can be seen that the test cylinder is composed of the upper arc 1 and the lower arc 2 made of aluminum alloy materials; the edges of the upper arc 1 and the lower arc 2 are provided with U-shaped grooves 3, and the two arcs pass through the U-shaped The slots are movably connected by bolts at equal intervals; the upper arc 1 and the lower arc 2 have the simulated transverse edge curves of the actual tunnel.

[0019] The shrinkable aluminum alloy tunnel lining model test technology indirectly simulates the variable stiffness of the tunnel through the scalability of the lining, and can realize the measurement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com