Preparation system and preparation method of TiN, TiC and TiCN powder

A technology of powder and inert gas, which is applied in the preparation process of TiCN powder, TiC and TiN, can solve the problems of difficult fluidization, low efficiency and high temperature of powder, and achieve economical raw materials, simple process flow and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

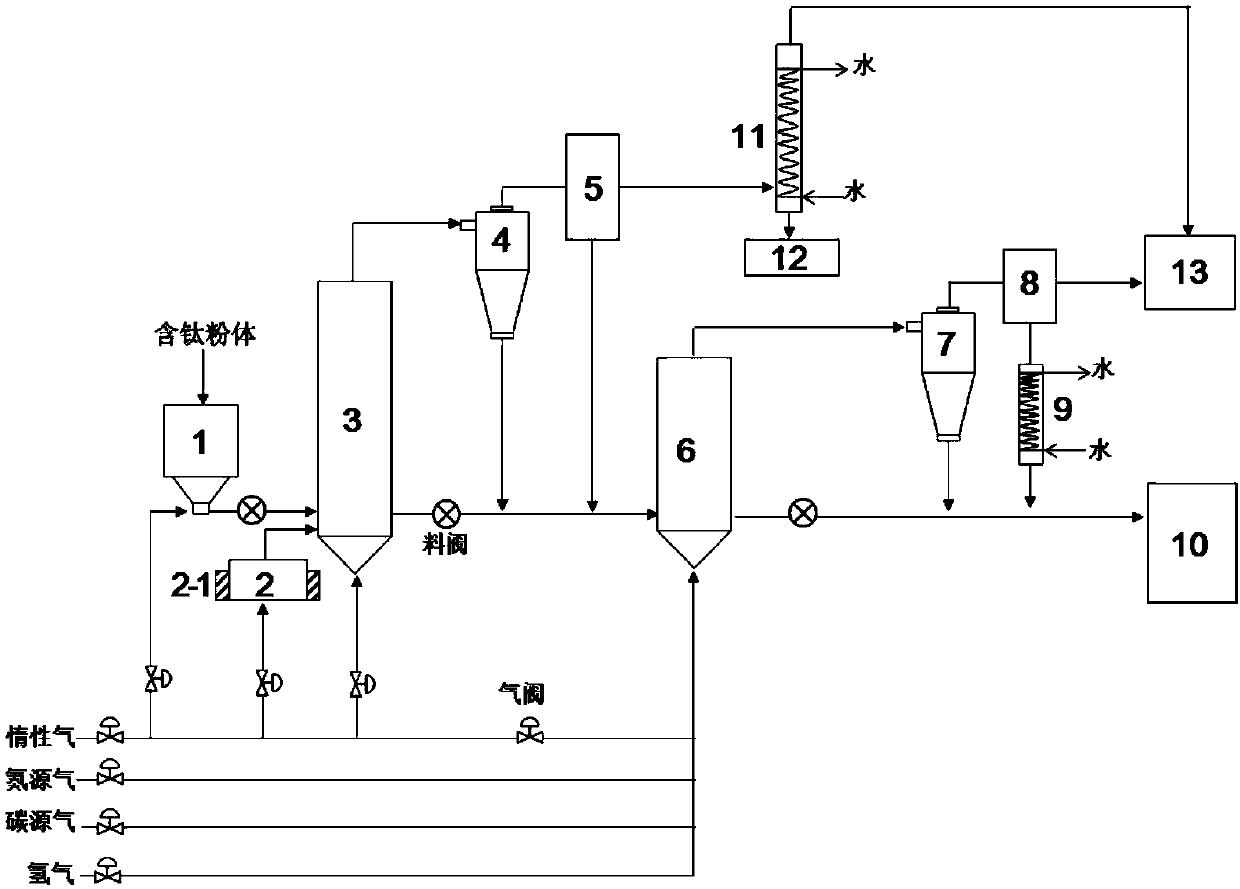

[0047] Combine figure 1 , The preparation system of TiN, TiC, TiCN powder in this embodiment includes a powder feeding device 1, TiCl 4 Evaporation device 2, heating device 2-1, pre-reaction fluidized bed 3, first cyclone separation device 4, first high temperature dust removal device 5, powder synthesis fluidized bed device 6, second cyclone separation device 7, second high temperature Dust removal device 8, first water cooling device 9, powder collection device 10, second water cooling device 11, TiCl 4 Recovery device 12, tail gas treatment device 13;

[0048] The air inlet at the bottom of the powder feeding device 1 is connected with an inert gas pipeline through a gas valve and a pipeline; the outlet at the bottom of the powder feeding device 1 and the inlet at the bottom of the pre-reaction fluidized bed 3 pass through The valve is connected to the pipeline;

[0049] The TiCl 4 The evaporation device 2 is equipped with the heating device 2-1; the TiCl 4 The air inlet of the ...

Embodiment 2

[0057] In this embodiment, the method for preparing TiN, TiC, and TiCN powders using the system in the above embodiment 1 specifically includes the following steps:

[0058] After the titanium-containing powder is cleaned by inert gas in the powder feeding device 1, it is transported to the pre-reaction fluidized bed 3 through a feed valve; the inert gas passes through the TiCl 4 Evaporator 2 puts gaseous TiCl 4 Loaded into the pre-reaction fluidized bed 3; the inert gas entering the bottom of the pre-reaction fluidized bed 3 maintains the titanium-containing powder in a fluidized state, and pre-reacts to obtain the pre-reaction product powder; the pre-reaction product powder The body enters the powder synthesis fluidized bed device through the discharge port of the pre-reaction fluidized bed 3, the discharge port of the first cyclone separation device 4, and the discharge port of the first high-temperature dust removal device 5 6; In the powder synthesis fluidized bed device 6, t...

Embodiment 3

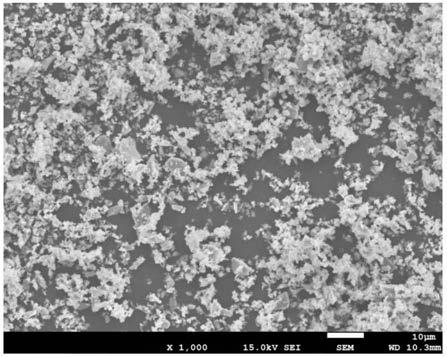

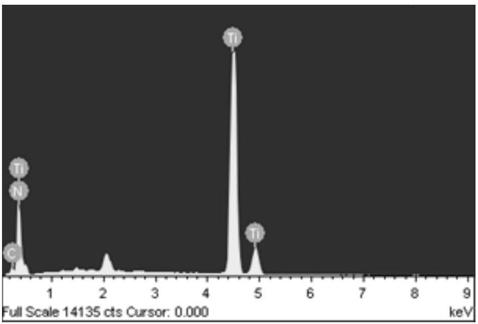

[0061] In this embodiment, on the basis of the above embodiment 2, the titanium-containing powder in the powder feeding device 1 is TiH 2 Powder with a purity of 99% and a particle size of 5μm; the inert gas is Ar; the nitrogen source gas is N 2 , H 2 The molar ratio of N to the nitrogen source is 1; the TiCl 4 The temperature of the evaporation device 2 is 30°C; the temperature in the pre-reaction fluidized bed 3 is 530°C, in which TiCl 4 With TiH 2 The molar ratio of the powder is 0.5, and the average residence time of the powder is 30 min; the temperature of the powder synthesis fluidized bed device 6 is 700°C, and the average residence time of the powder is 30 min; the nitrogen in the powder synthesis fluidized bed device 6 The molar content of N in the source gas and the TiCl in the pre-reaction fluidized bed 3 4 And the total molar ratio of Ti in the titanium-containing powder is 1. figure 2 To prepare the SEM scan picture of TiN powder, the average particle size of TiN pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com