A high-efficiency cage-shaped needle nozzle electrospinning device and its application in the preparation of inorganic material nanofibers

A cage needle, electrospinning technology, used in nanotechnology, nanotechnology, fiber processing, etc. for materials and surface science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

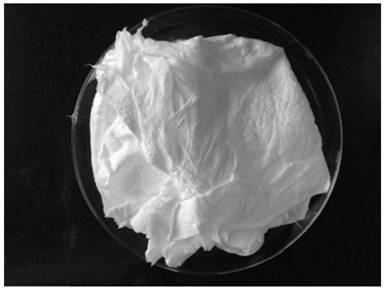

Embodiment 1

[0094] (1) Add 3.0790g of aluminum sec-butoxide to a mixed solvent containing 3.12mL of n-propanol, 2.08mL of isobutanol, and 1.57mL of acetylacetone, stir and seal for 1 hour to form a light yellow solution; Add absolute ethanol and 0.7g deionized water, then slowly add 1.63mL concentrated nitric acid dropwise, stir for 5-6h to obtain a transparent aluminum sol; add poloxamer surfactant F127 to the aluminum sol, and then add 3- 10 g of a 15 wt % polyvinyl alcohol aqueous solution is stirred at room temperature for 1-2 h until a transparent and uniform spinnable solution is formed. Among them, Al 3+ : EtOH: The molar ratio of poloxamer surfactant F127 is 1:30-50:0008-0.018, and the viscosity of the spinnable solution is controlled at 100-200mPa·S.

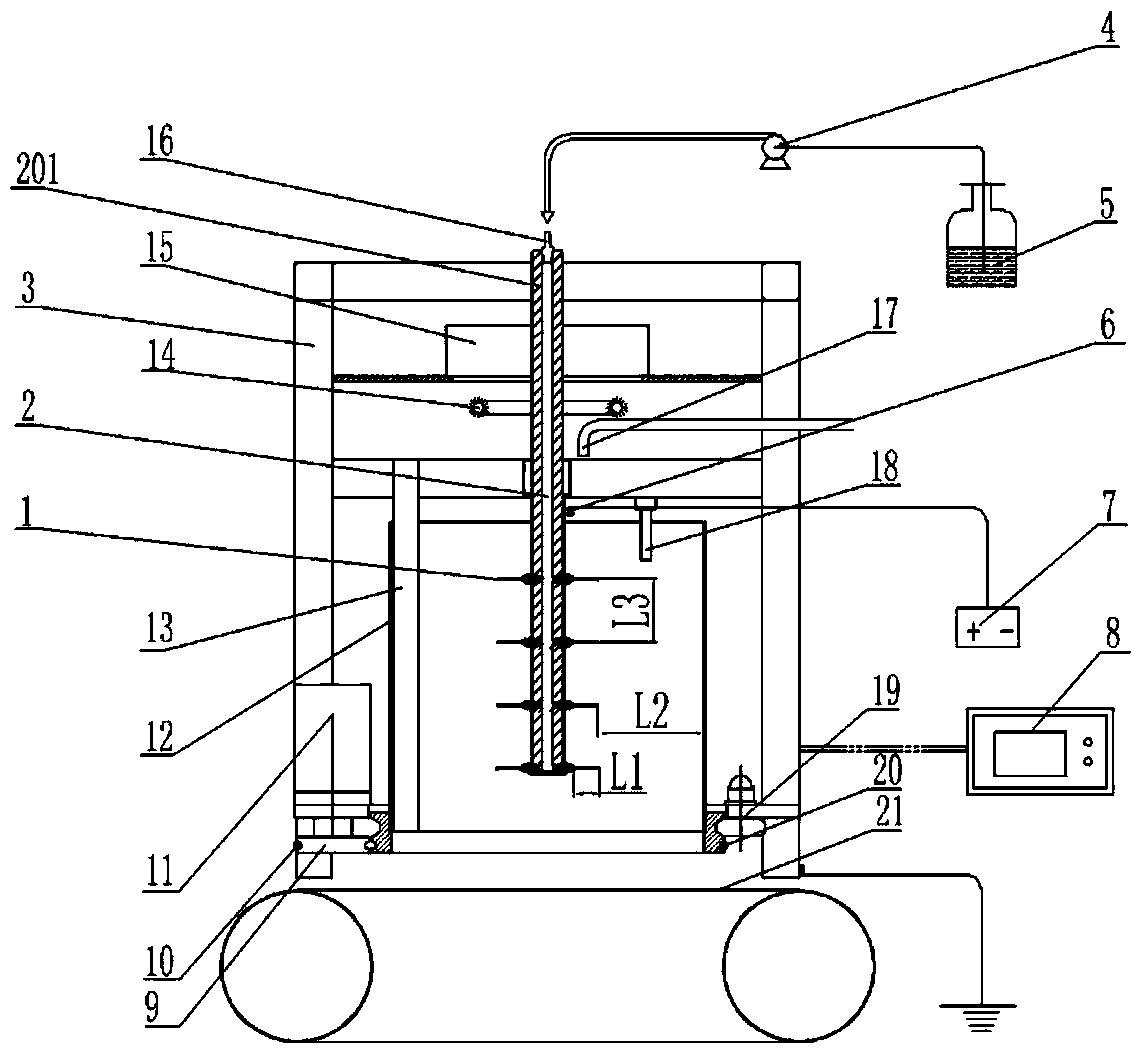

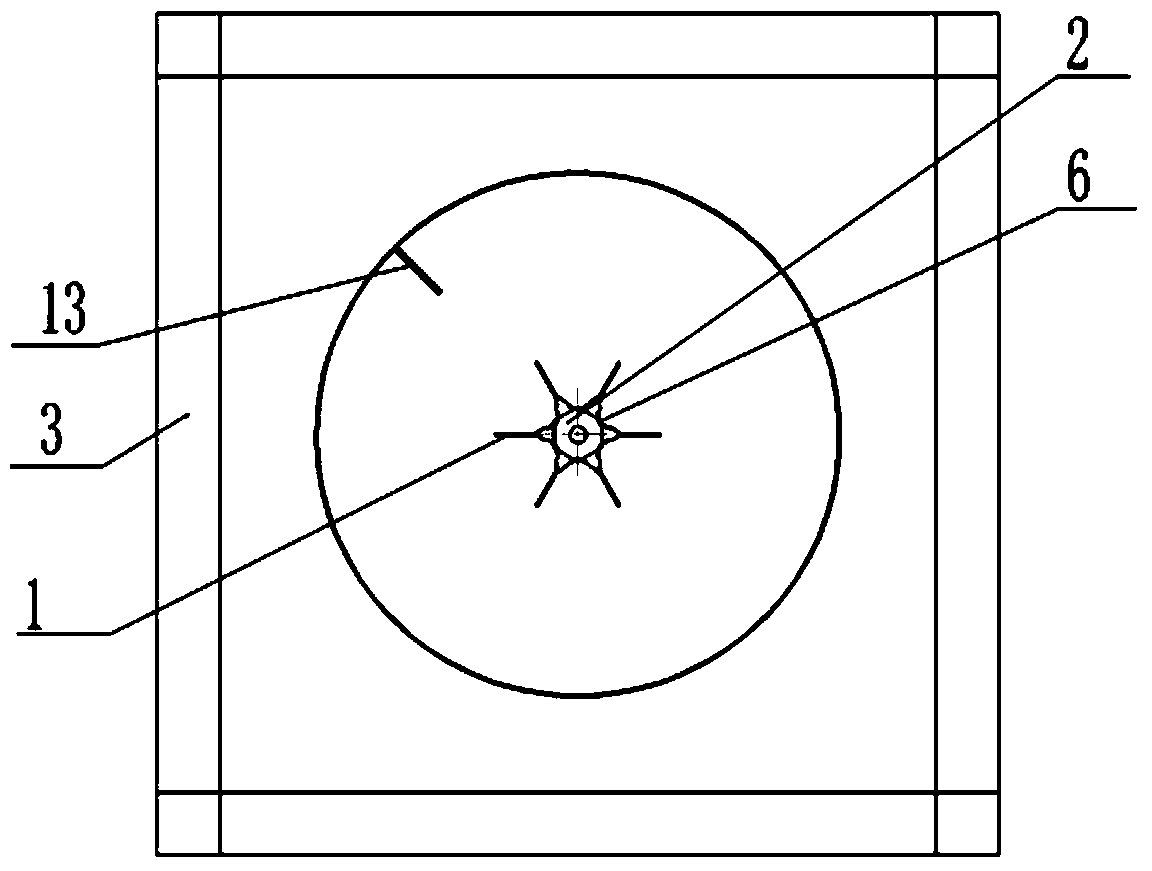

[0095] (2) Spinning process: the spinnable solution obtained in (1) is assembled into the device of the present invention for spinning. The number of installed nozzle groups is 4, the distance L1 from the nozzle end to the outer ...

Embodiment 2

[0100] (1) Quickly transfer 3.079g of aluminum sec-butoxide to 32g of absolute ethanol, stir, and then add Ce(NO 3 ) 3 ·6H 2 O 0.1085g, stir to dissolve, then add 0.63mL deionized water and 1.63mL HNO 3 , hydrolyzed for 6-8h; then, add 3g of poloxamer surfactant F127, add 10g of PVA aqueous solution with a mass fraction of 3-15wt%, stir and dissolve to form a transparent spinnable solution; control the viscosity of the spinnable solution at 100 -200mPa·S;

[0101] (2) Assemble the spinnable solution obtained in (1) into the device of the present invention for spinning. The number of installed nozzle groups is 1, the distance L1 from the end of the nozzle to the outer wall of the support body = 25mm (i.e. about the length of the nozzle), the distance from the end of the nozzle to the inner wall of the receiving part 12 = 200mm (i.e. the receiving distance), the nozzles of each nozzle group The number is 6, the longitudinal distance L3=225mm between adjacent nozzle groups, s...

Embodiment 3

[0105] The difference with Example 2 is: in step (1), add 0.2171g Ce (NO 3 ) 3 ·6H 2 O; adopt the same device assembly parameters as in Example 2 to carry out spinning, and step (2) and step (3) are the same as in Example 2.

[0106] The resulting CeO 2 / Al 2 o 3 The diameter of the composite fiber is between 100-500nm, the alumina content is 88wt%, CeO 2 The content is 12wt%; the surface of the nanofiber is composed of several nanometers of alumina particles, and several nanometers of cerium oxide particles are uniformly dispersed in the mesoporous structure of alumina, with an average pore diameter of 6nm and a specific surface area of 120m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com