Apparatus and process of producing electronics level high purity hydrochloric acid

A technology of electronic chemicals and semi-finished products, applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems of high energy consumption, low output rate, and difficulty in large-scale rectification, and achieve low energy consumption and high output The effect of high efficiency and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

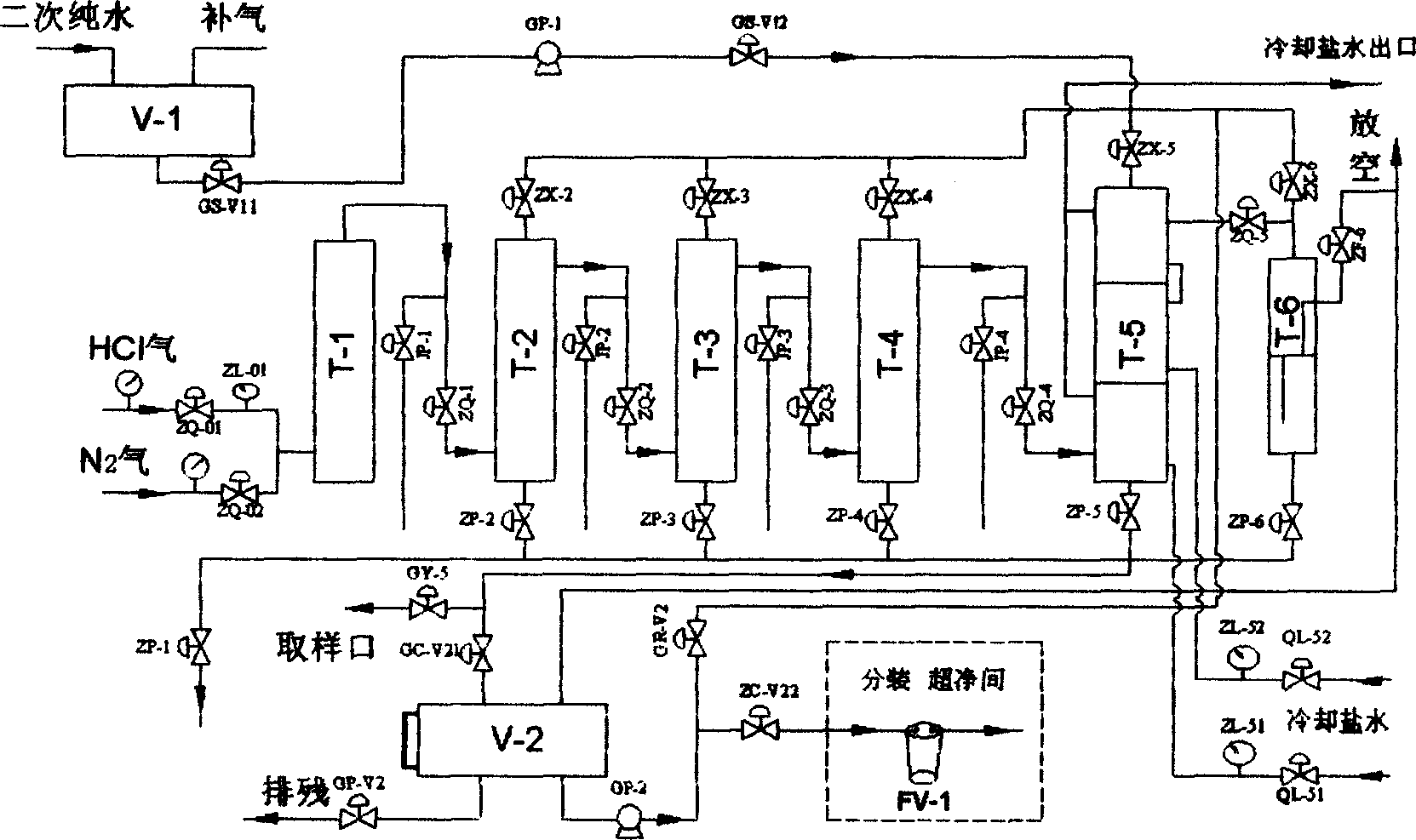

[0049] The specific embodiment of process of the present invention is as follows

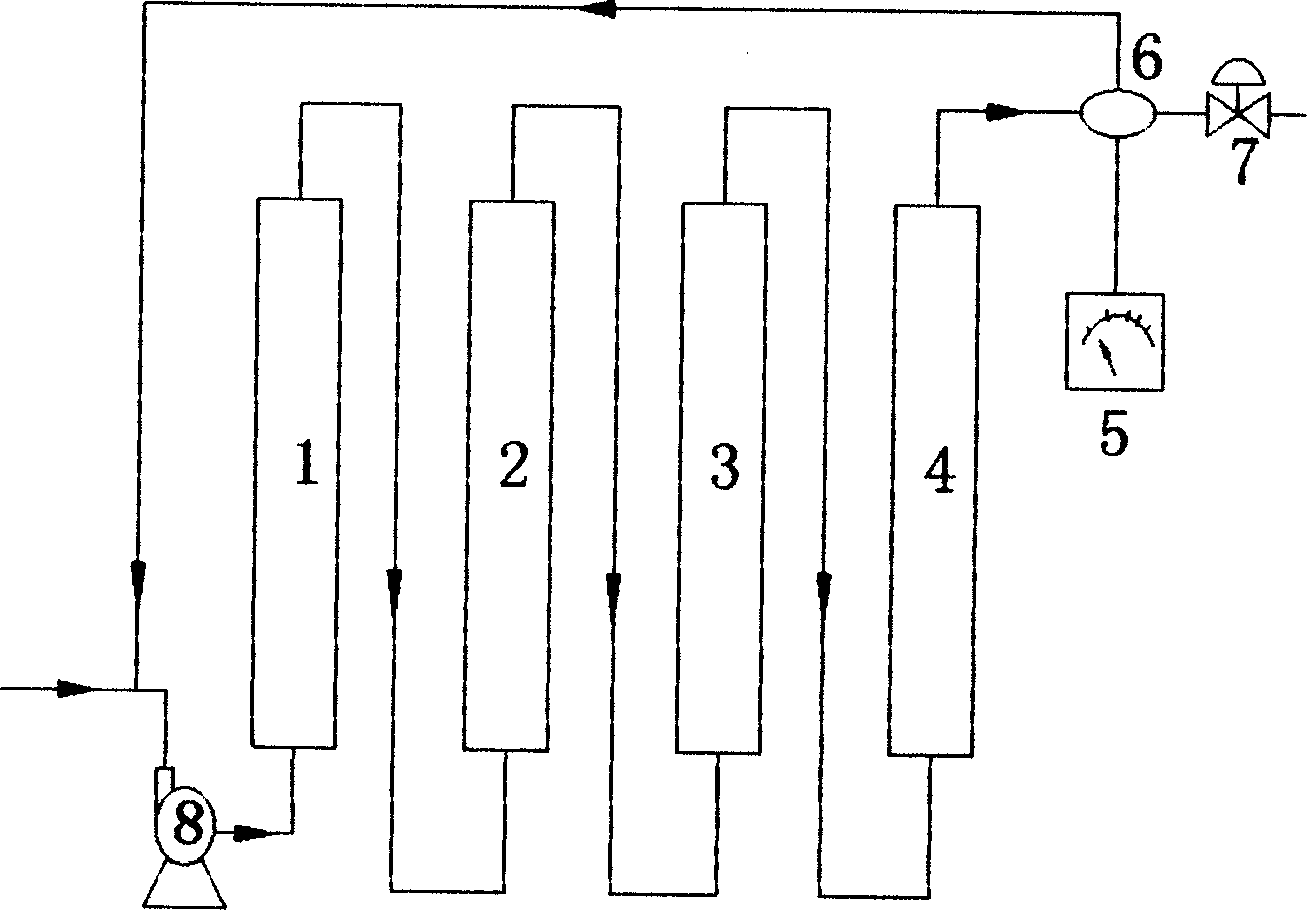

[0050] The pressure of hydrogen chloride gas is 0.15MPa, measured by a mass flow meter ZL-01, and connected with a tee through a regulating valve. The pressure of nitrogen is 0.15MPa and it is connected with the tee. Hydrogen chloride gas and nitrogen gas are mixed in the tee and enter the purification tower T-1. T-1 is filled with coconut shell modified activated carbon. The activated carbon can remove oil and low-carbon organic compounds and iron and copper in the raw material gas. For metal impurities, the working temperature of the tower should be lower than 35°C, otherwise the impurities adsorbed by the activated carbon will be decomposed and enter the next stage, and even the absorption tower will seriously affect the product quality.

[0051] Connections from T-1 to T-6 are made of glass, quartz, and PTFE material. Due to the strict requirements for high-purity reagents, it is strictly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com