Device and method for continuously and rapidly preparing graphene thin film on copper foil

A technology of graphene film and copper foil, which is applied in graphene, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of continuous rapid preparation and continuous large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

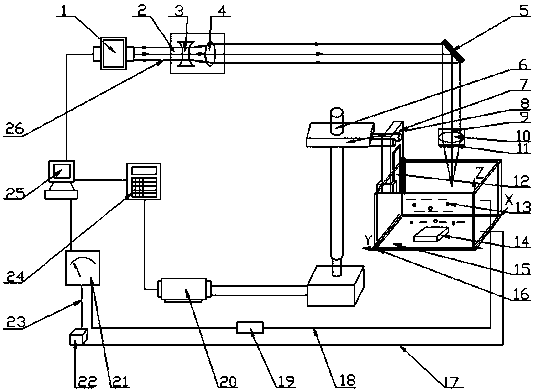

[0018] The technical solution of the present invention will be described in more detail below in conjunction with the drawings, but it is not used to limit the present invention.

[0019] Such as figure 1 As shown, a device for continuous and rapid preparation of graphene films on copper foil includes a laser generating system and a reaction vessel 15 located below the laser generating system. The left end of the reaction vessel 15 is provided with a screw nut device 6, and the wire An acrylic plate 7 is installed at the output end of the screw nut device 6, and a copper foil 12 is installed on the acrylic plate 7. The acrylic plate 7 and the copper foil 12 are both located in the reflecting container 15. The screw nut device 6 Driven by the motor 20, the acrylic plate 7 can be moved vertically in the reflection container 15; the reaction container 15 contains a graphite 13 suspension and a magnetic stirrer 14. The reaction container 15 contains deionized water; a laser processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com