Method for recovering and using aluminum-plastic composite film

A technology of aluminum-plastic composite film and reactor, which is applied in the preparation of liquid hydrocarbon mixtures, the improvement of process efficiency, and the petroleum industry. It can solve the problems of high recycling costs, environmental pollution, and single types of solvents, and achieve broad economic significance and Social significance, solving environmental pollution problems, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

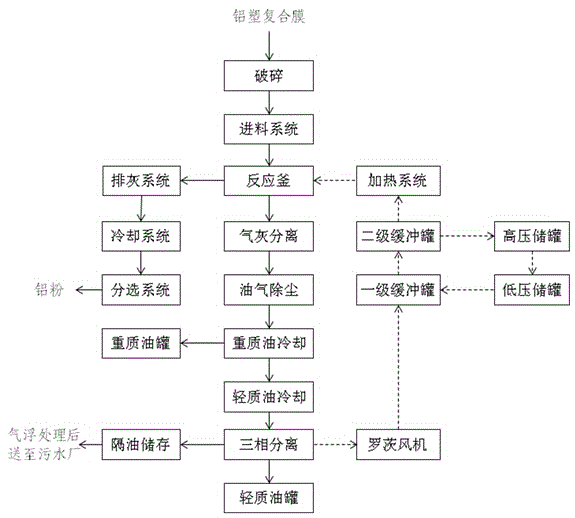

[0020] Such as figure 1 Shown, a kind of method for recycling aluminum-plastic composite film comprises the following steps:

[0021] (1) Break the waste aluminum-plastic composite film, and then enter the silo through the conveying system;

[0022] The moisture content of the waste aluminum-plastic composite film is basically below 10% after being packed, so it does not need to be dried or dried in the sun. The plastic composite film is transported to the intermediate silo by the belt conveyor. When the feeding system feeds the material, the belt conveyor automatically transports it to the silo. The material in the silo falls into the hopper by its own gravity and is compacted by the flap.

[0023] (2) The crushed waste aluminum-plastic composite film enters the reactor through the feed system for high-temperature pyrolysis, and the reaction temperature is 350~500°C;

[0024] The material compacted by the flap is fed through the hydraulic jacking cylinder, and the feeding a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com