Patents

Literature

32results about How to "Improve lithium ion mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

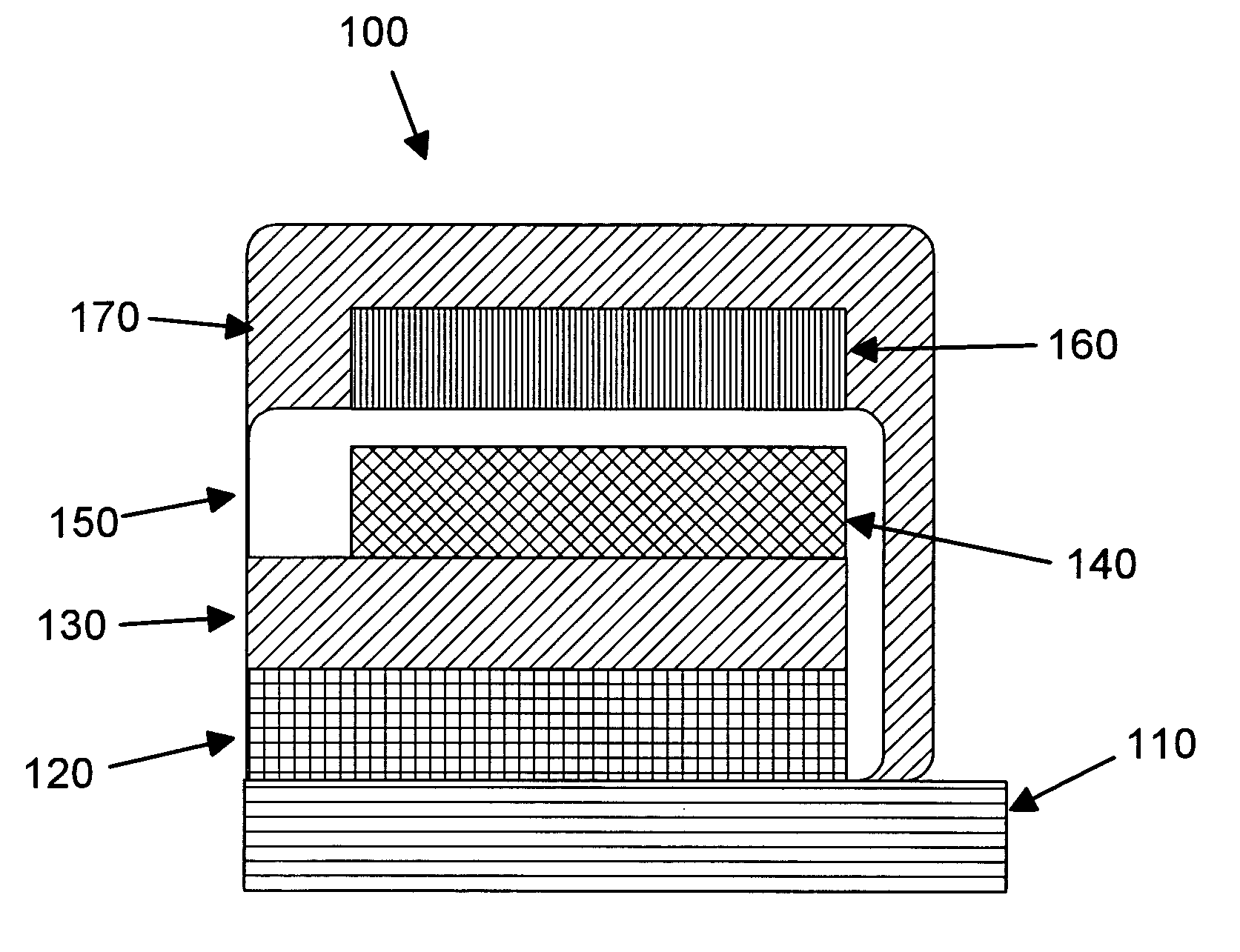

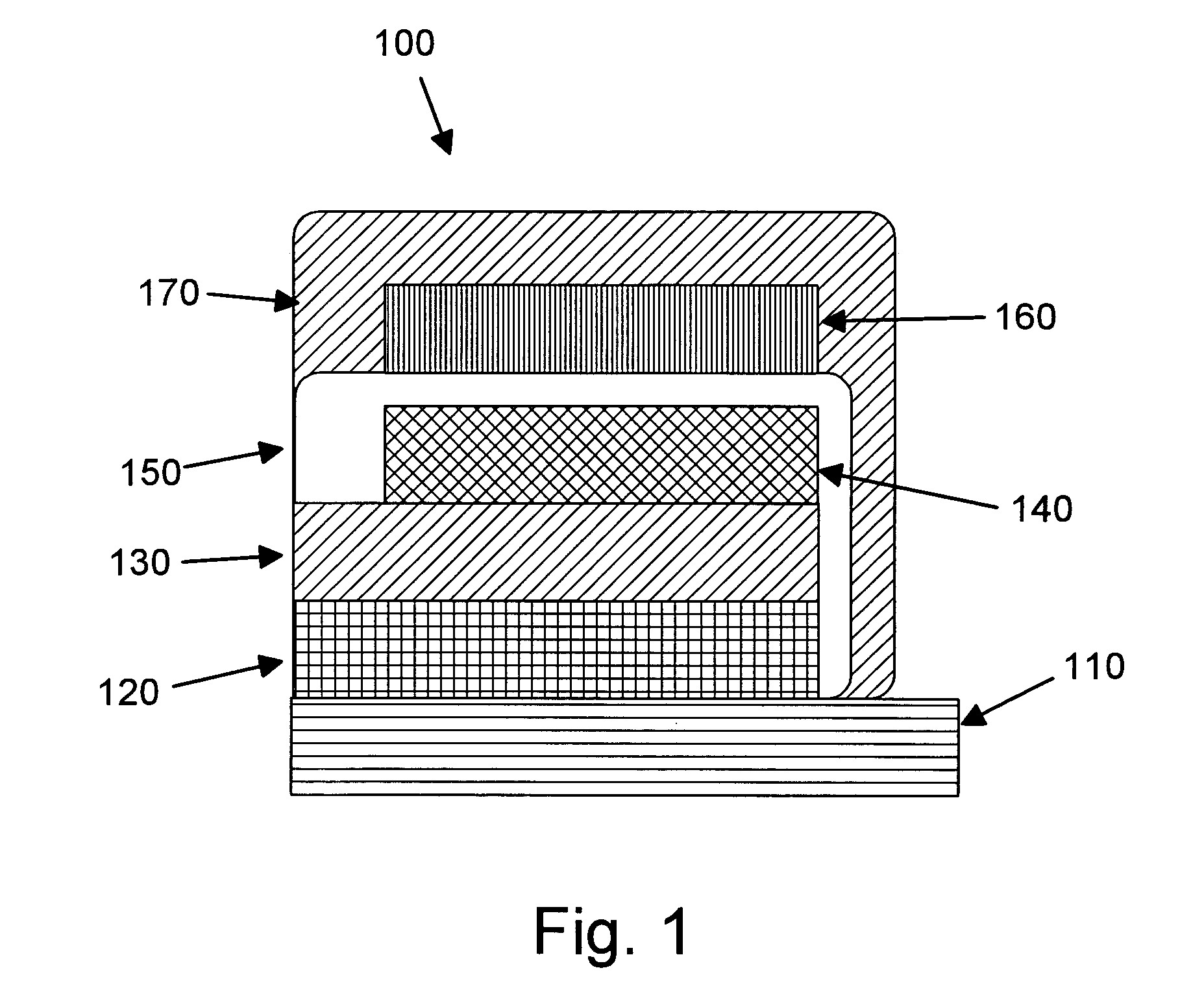

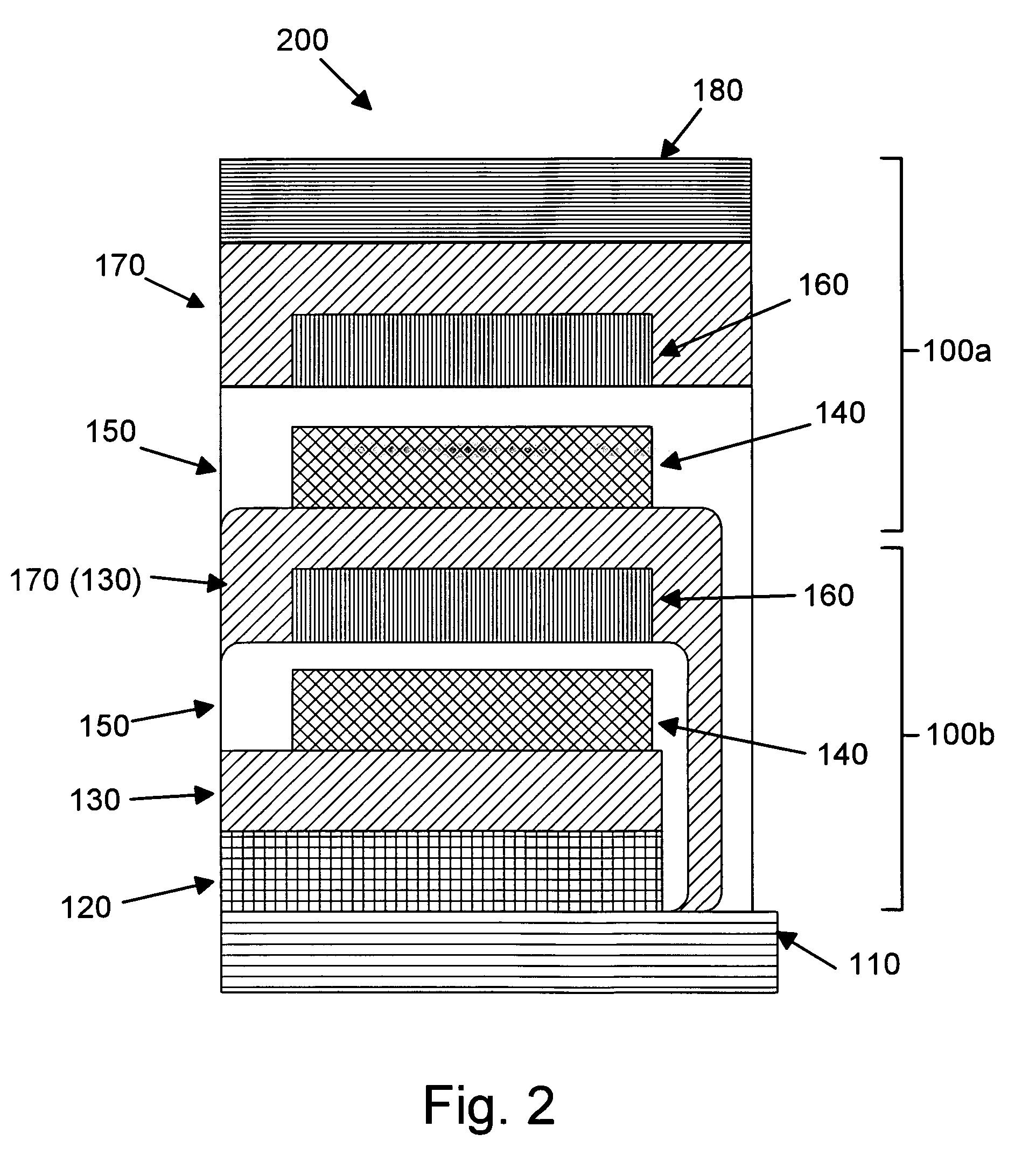

Rechargeable thin film battery and method for making the same

InactiveUS6982132B1Improve lithium ion mobilityHigh voltageElectrode thermal treatmentFinal product manufactureElectrical batteryHigh energy

A rechargeable, stackable, thin film, solid-state lithium electrochemical cell, thin film lithium battery and method for making the same is disclosed. The cell and battery provide for a variety configurations, voltage and current capacities. An innovative low temperature ion beam assisted deposition method for fabricating thin film, solid-state anodes, cathodes and electrolytes is disclosed wherein a source of energetic ions and evaporants combine to form thin film cell components having preferred crystallinity, structure and orientation. The disclosed batteries are particularly useful as power sources for portable electronic devices and electric vehicle applications where high energy density, high reversible charge capacity, high discharge current and long battery lifetimes are required.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

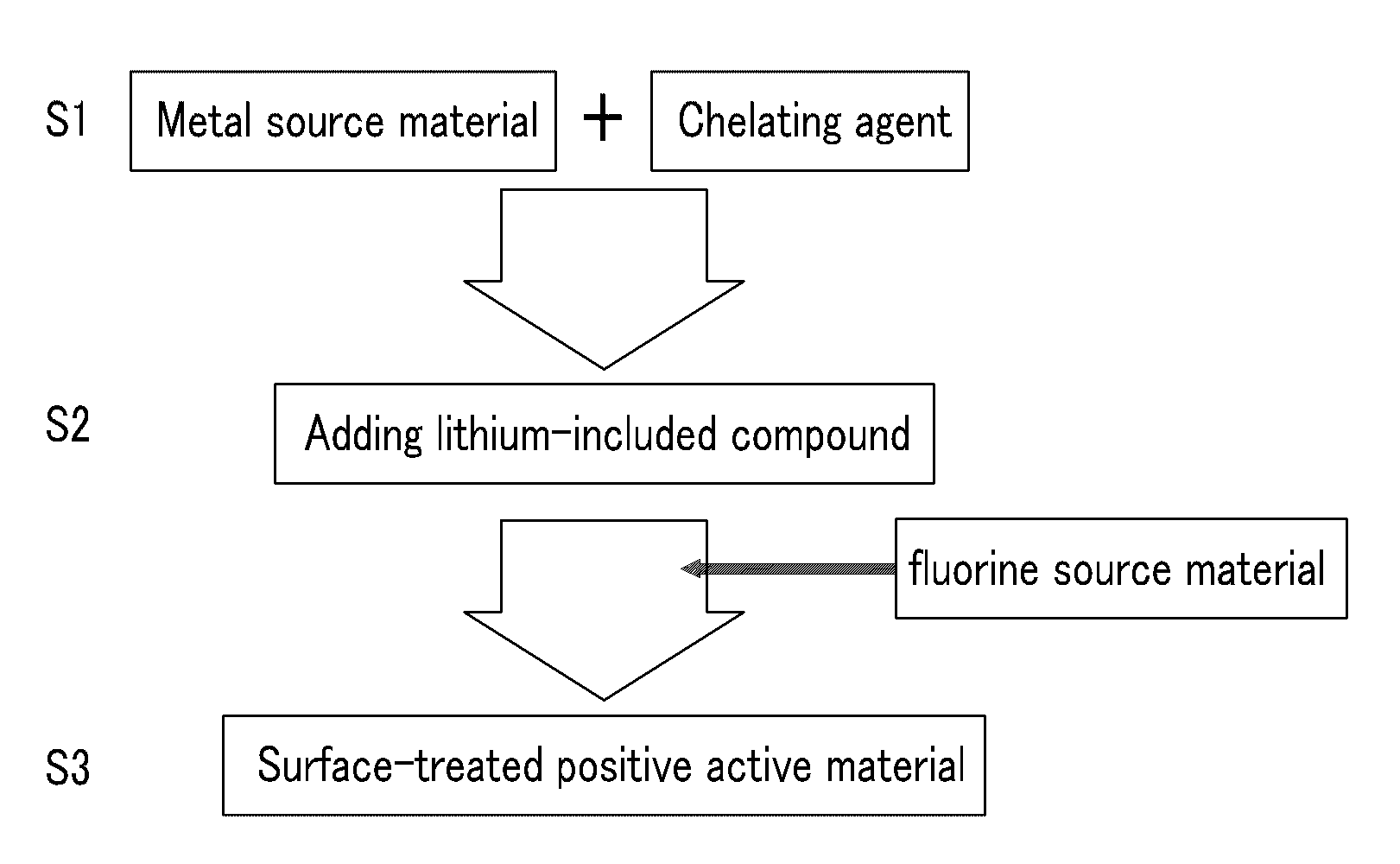

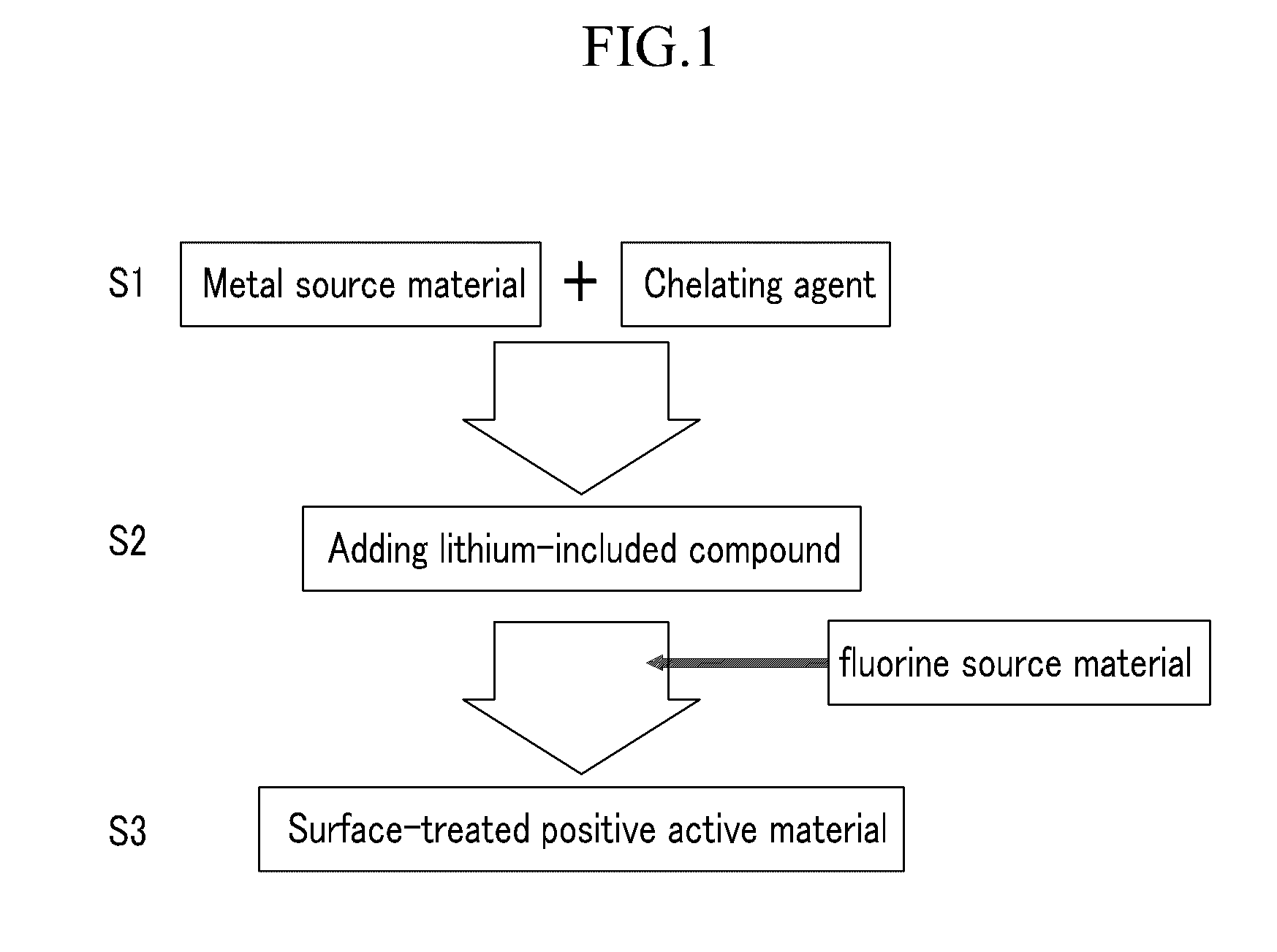

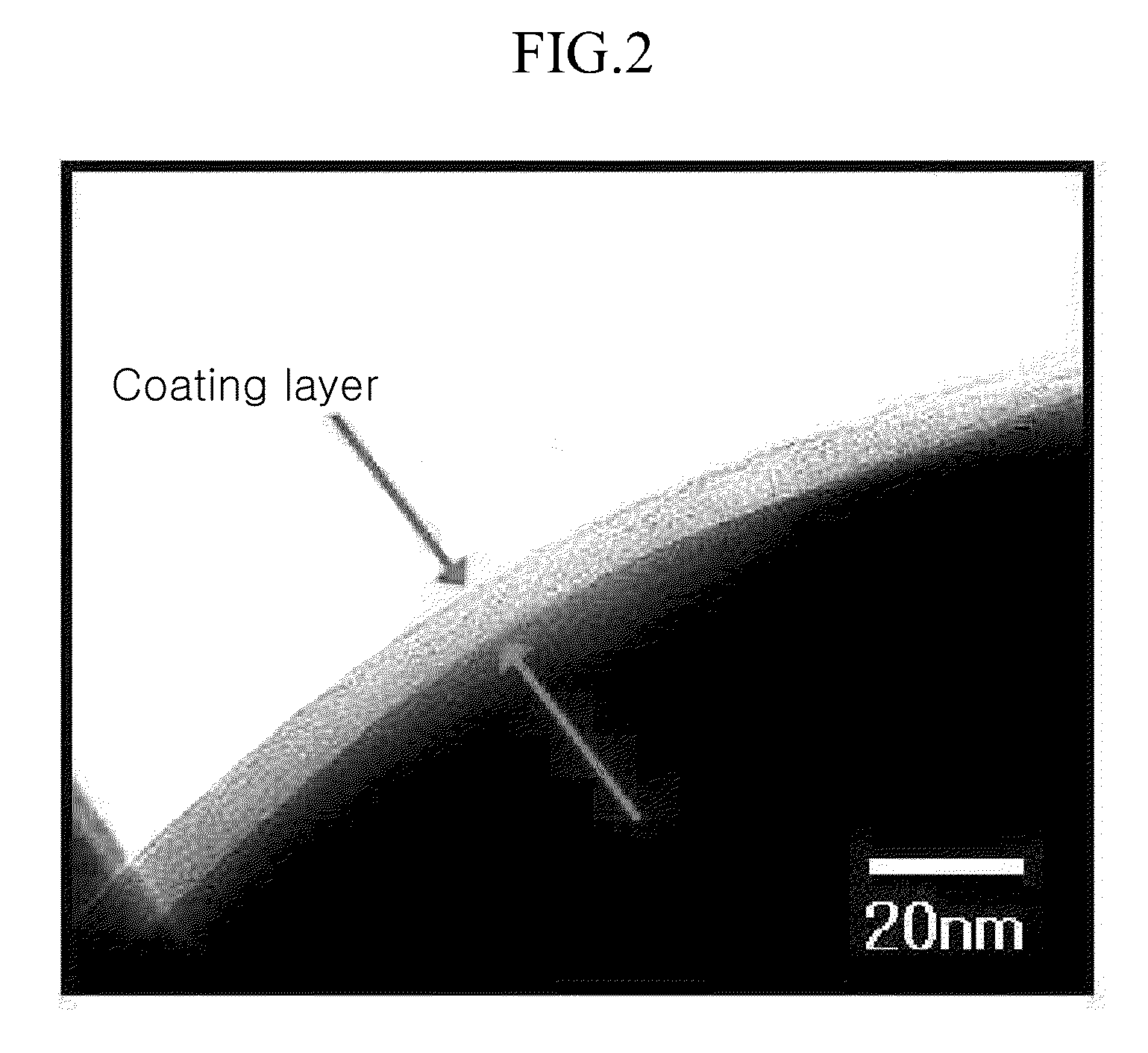

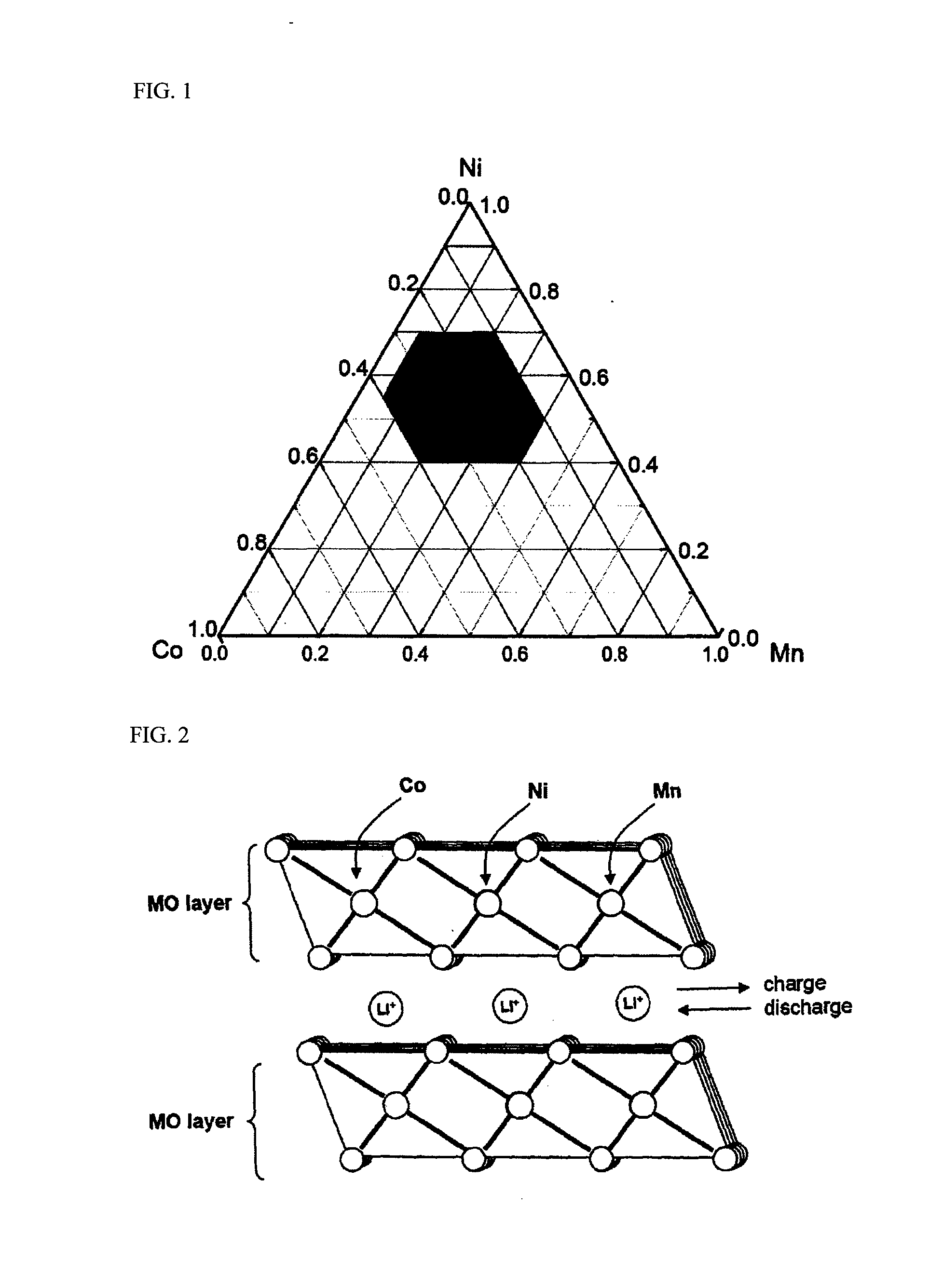

Method of preparing positive active material for rechargeable lithium battery, positive active material for rechargeable lithium battery prepared by same, and rechargeable lithium battery including positive active material

InactiveUS20090253042A1Improve mobilityHigh characteristicsNon-aqueous electrolyte accumulator electrodesLi-accumulatorsSource materialConductive materials

The present invention relates to a method of preparing a positive active material for a rechargeable lithium battery, a positive active material prepared according to the method, and a rechargeable lithium battery including the same. This manufacturing method includes preparing a complex salt solution by mixing a solution including a metal source material and a chelating agent, disposing the complex salt on the surface of a lithium-included compound by adding a lithium-included compound to the complex salt solution, adding a solution including a fluorine source material to the solution including a lithium-included compound with the complex salt on the surface, and heat-treating the mixture. The present invention provides a simple method of economically preparing a positive active material in which structural transition on the surface is prevented and securing a uniform coating layer. In addition, the positive active material can have improved charge and discharge characteristics, cycle life characteristic, and rate characteristic. It also has improved ion conductivity, and accordingly can improve mobility of lithium ions in an electrolyte and thereby improve discharge potential of a battery. Furthermore, the positive active material can decrease the amount of a conductive material and increase density of a substrate.

Owner:ENERCERAMIC

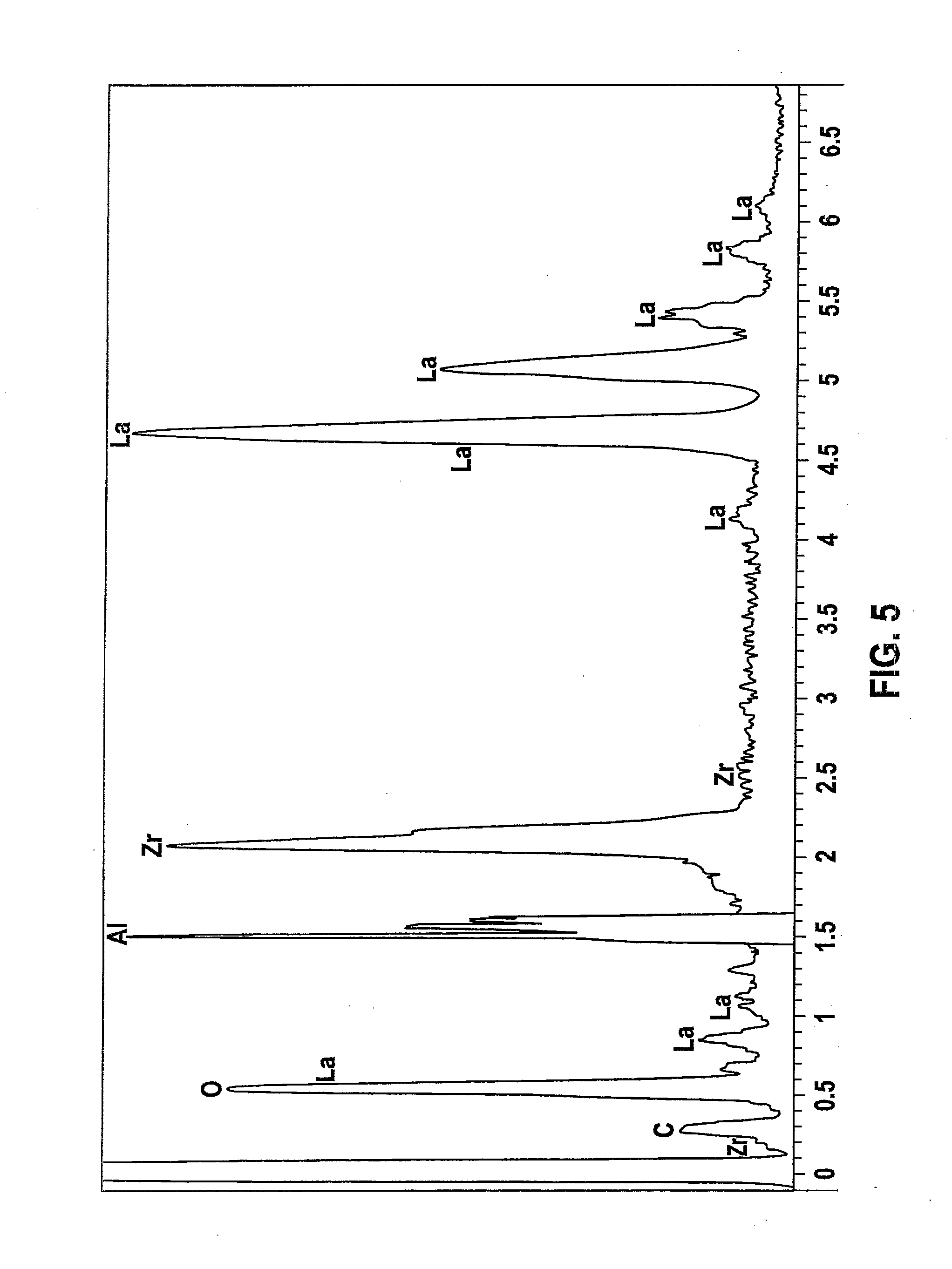

Lithium ion-conducting garnet-like compounds

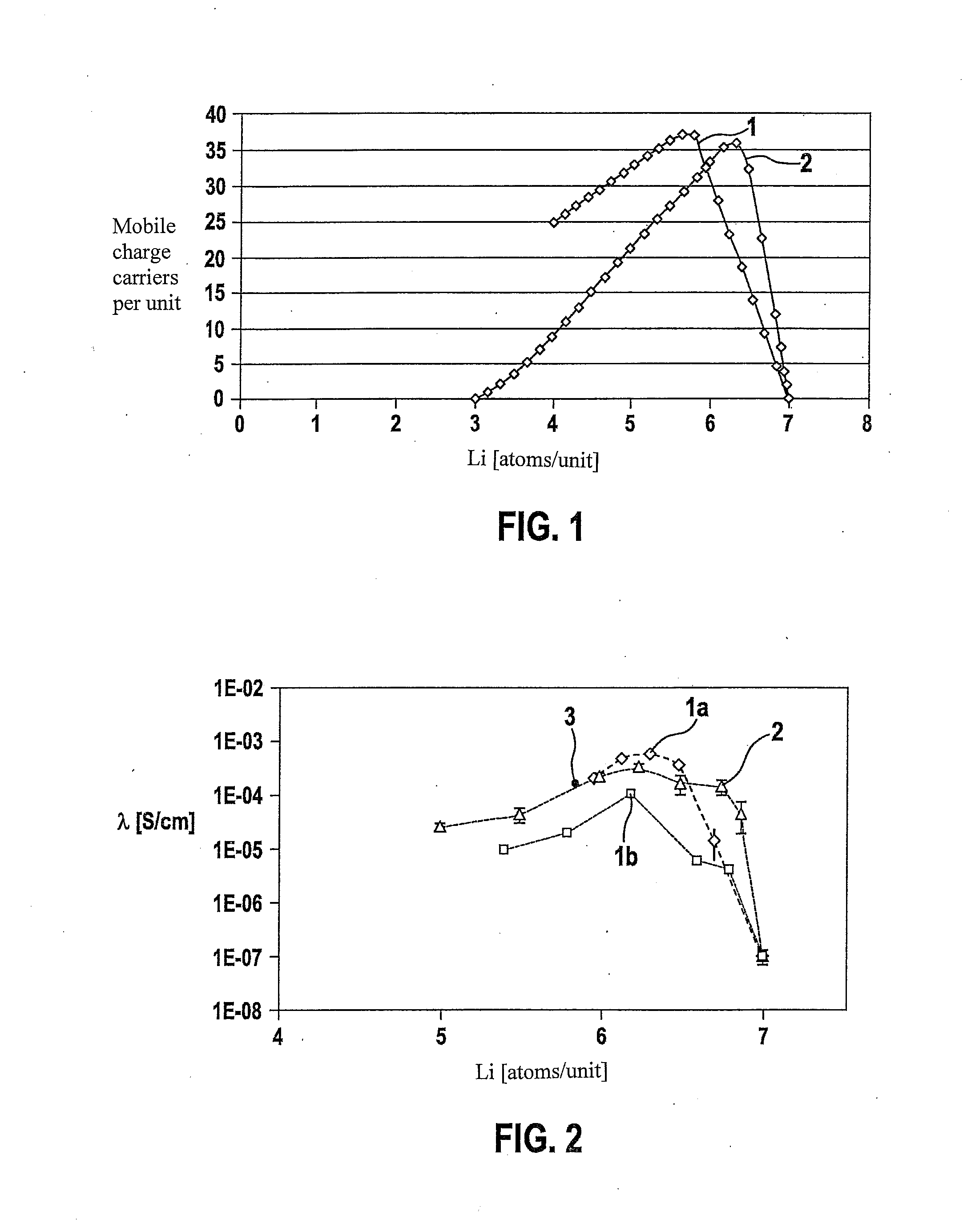

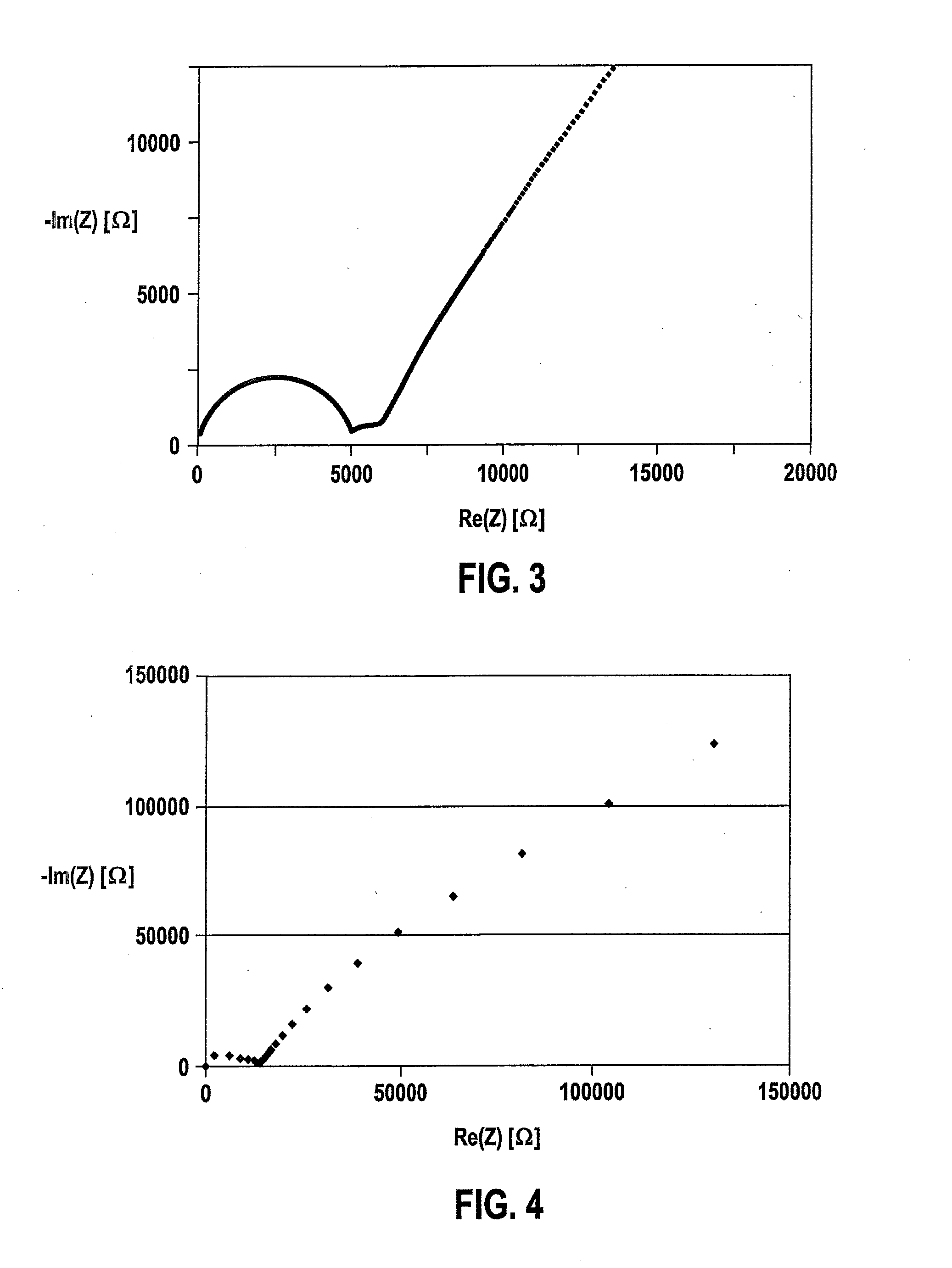

ActiveUS20140295287A1Loss can be compensatedImprove stabilityTantalum compoundsZirconium compoundsLithiumCompound a

A lithium ion-conducting compound, having a garnet-like crystal structure, and having the general formula: Lin[A(3-a′-a″)A′(a′)A″(a″)][B(2-b′-b″)B′(b′)B″(b″)][C′(c′)C″(c″)]O12, where A, A′, A″ stand for a dodecahedral position of the crystal structure, where A stands for La, Y, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm and / or Yb, A′ stands for Ca, Sr and / or Ba, A″ stands for Na and / or K, 0<a′<2 and 0<a″<1, where B, B′, B″ stand for an octahedral position of the crystal structure, where B stands for Zr, Hf and / or Sn, B′ stands for Ta, Nb, Sb and / or Bi, B″ stands for at least one element selected from the group including Te, W and Mo, 0<b′<2 and 0<b″<2, where C and C″ stand for a tetrahedral position of the crystal structure, where C stands for Al and Ga, C″ stands for Si and / or Ge, 0<c′<0.5 and 0<c″<0.4, and where n=7+a′+2·a″−b′−2·b″−3·c′−4·c″ and 5.5<n<6.875.

Owner:ROBERT BOSCH GMBH

Solid electrolyte and all-solid state lithium ion secondary battery

InactiveUS20150044575A1High electronegativityImprove lithium ion mobilityElectrolytic capacitorsFinal product manufactureAll solid statePhysical chemistry

In a Li ion conductivity oxide solid electrolyte containing lithium, lanthanum, and zirconium, a part of oxygen is substituted by an element M (M=N, Cl, S, Se, or Te) having smaller electronegativity than oxygen.

Owner:HITACHI LTD

Additive for electrolyte solution, non-aqueous electrolyte solution including the additive and lithium secondary battery including the electrolyte solution

ActiveUS20140011081A1Improve featuresReduce resistanceCell electrodesLi-accumulatorsPhysical chemistryLithium-ion battery

An additive for an electrolyte solution includes a lithium salt having an oxalato complex as an anion and a compound represented by following Chemical Formula 1.Wherein, a represents C or Si, b represents H or F, and n represents an integer of 1 to 5. A non-aqueous electrolyte solution including the additive and a lithium secondary battery including the electrolyte solution also are provided.

Owner:LG ENERGY SOLUTION LTD

Organic-inorganic silicon structure-containing block copolymer, electrolyte including the same, and lithium battery including the electrolyte

ActiveUS20160072148A1Improve ionic conductivityImprove mechanical propertiesSolid electrolytesIon-exchanger regenerationPolymer scienceSide chain

An organic-inorganic silicon structure-containing block copolymer including a first domain including an ion conductive polymer block; and a second domain including a polymer block including a non-conducting polymer and an organic-inorganic silicon structure, wherein the organic-inorganic silicon structure is connected to a side chain connected to a backbone of the non-conducting polymer.

Owner:SAMSUNG ELECTRONICS CO LTD

Silicon oxide-graphene coated high-nickel lithium battery anode material and preparation method

InactiveCN108390037AOptimize volumeImprove structural stabilityMaterial nanotechnologyCell electrodesOrganic solventNickel–lithium battery

The invention provides a silicon oxide-graphene coated high-nickel lithium battery anode material and a preparation method. A lithium source, a nickel source, a cobalt source, a manganese source and an accessory solvent are prepared into a high-nickel ternary precursor sizing agent by mixing and ball-grinding; a silk screen fixed with nano-sized mesoporous silicon oxide microballoons is dipped into the sizing agent; later, a high-nickel ternary powder material supported by silica dioxide is obtained by pre-sintering, sintering, ultrasonic smashing and grinding; and then, the high-nickel ternary powder is arranged in an organic solvent and configured into turbid liquid; a graphene slice layer is stripped off by a physical means, the turbid liquid is added, and stirring is carried out; low-temperature heat treatment is performed after filtering and drying; and the silicon oxide-graphene coated high-nickel ternary anode material is obtained. According to the anode material and the preparation method in the invention, the problems that the structure of the high-nickel ternary anode material collapses and volume deforms seriously during the lithium ion deintercalation process under thecondition of maintaining capacity and rate performance; the process is simple, and continuous production is facilitated.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Electrolyte additive, lithium secondary battery and non-aqueous electrolyte comprising additive

ActiveCN103597647ALower resistanceImproved cycle life characteristicsCell electrodesLi-accumulatorsPhosphatePhysical chemistry

Owner:LG ENERGY SOLUTION LTD

Phenyl organic acid compound modified graphite negative electrode material and preparation method thereof

ActiveCN111490238AExcellent lithium ion conductivityLower impedanceSecondary cellsNegative electrodesElectrical batteryCarboxylic acid

The invention belongs to the technical field of battery negative electrode materials, and provides a phenyl organic acid compound modified graphite negative electrode material, the negative electrodematerial comprises a phenyl organic acid compound and graphite, and the weight ratio of the phenyl organic acid compound to the graphite is 1-6: 100; according to the structural general formula of thephenyl organic acid compound, RA1 is a hydrocarbyl organic acid group containing a carbon-carbon single bond, a carbon-carbon double bond or a carbon-carbon triple bond, and the organic acid group isone or two of sulfonic acid, phosphonic acid, boric acid and carboxylic acid. The invention also provides a preparation method of the negative electrode material. According to the preparation method,the first coulombic efficiency of the graphite negative electrode is remarkably improved, the lithium consumption caused by rupture and reforming of a SEI membrane in the long-term cycle process of the battery is greatly reduced, and the long-term cycle stability and the high-temperature cycle stability of the battery are remarkably improved.

Owner:苏州华赢新能源材料科技有限公司

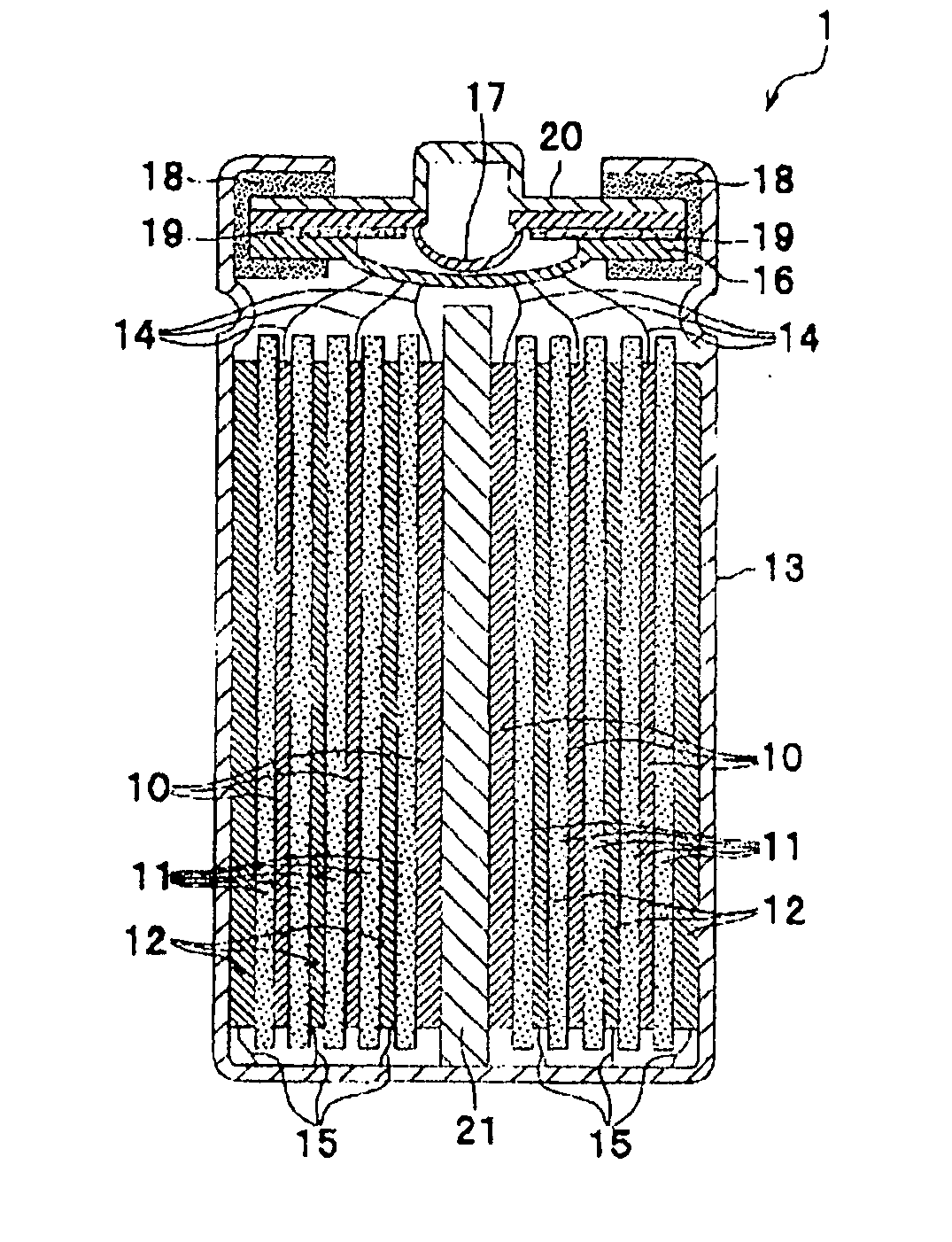

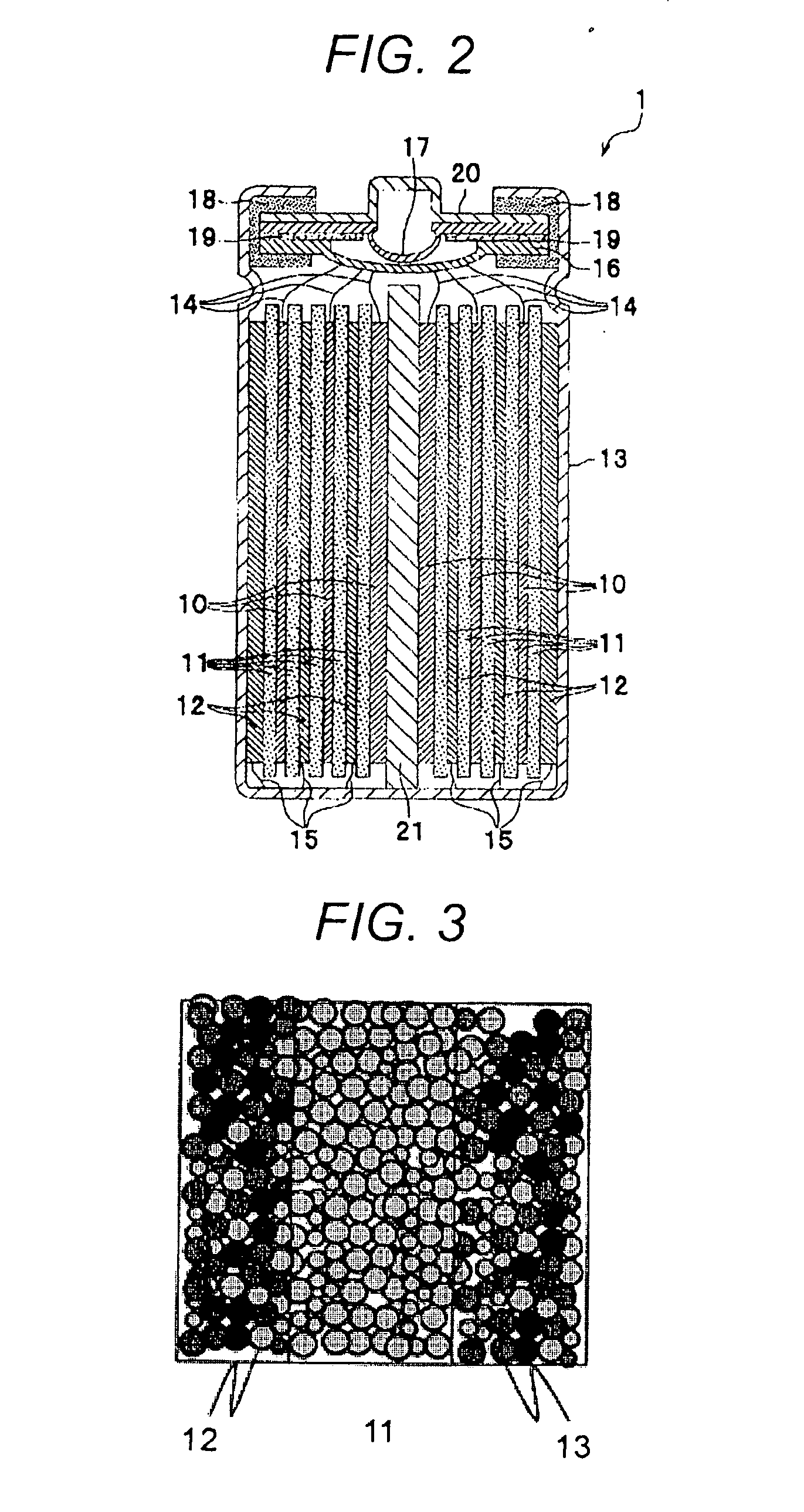

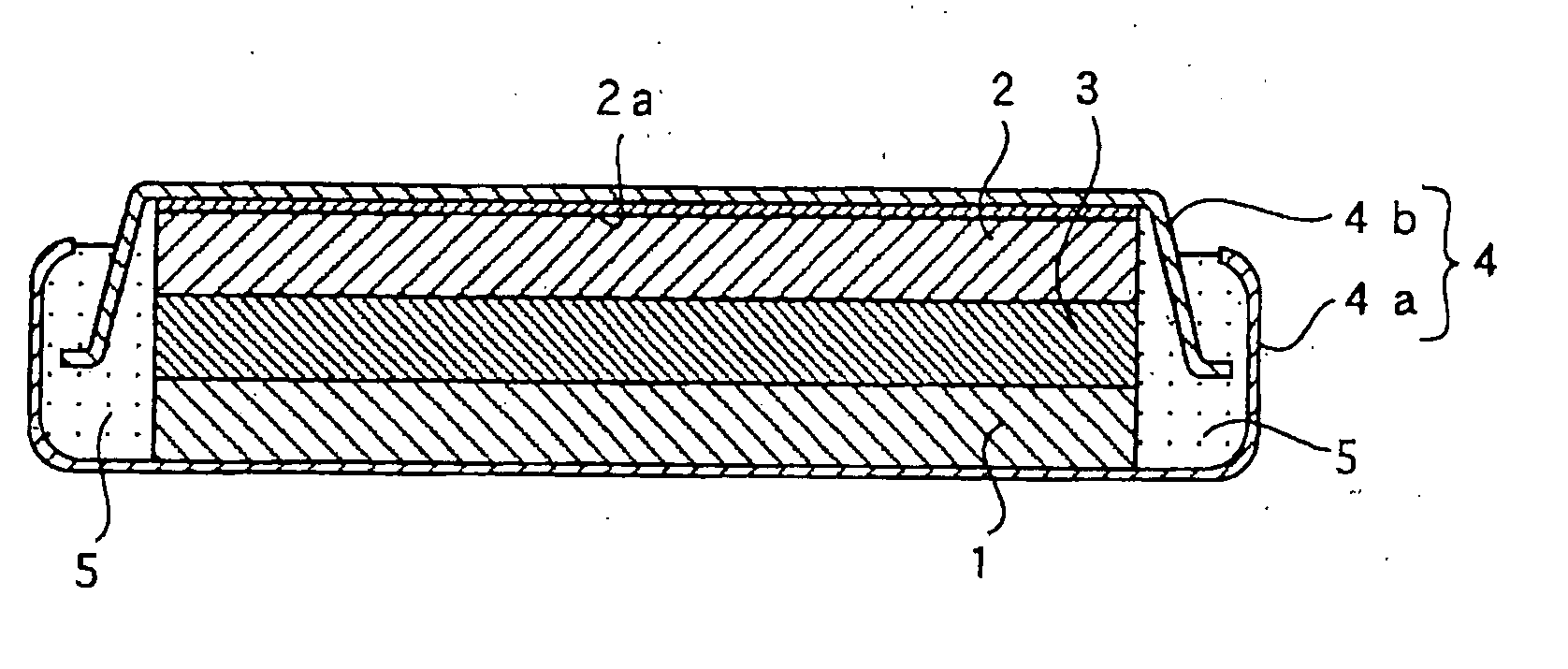

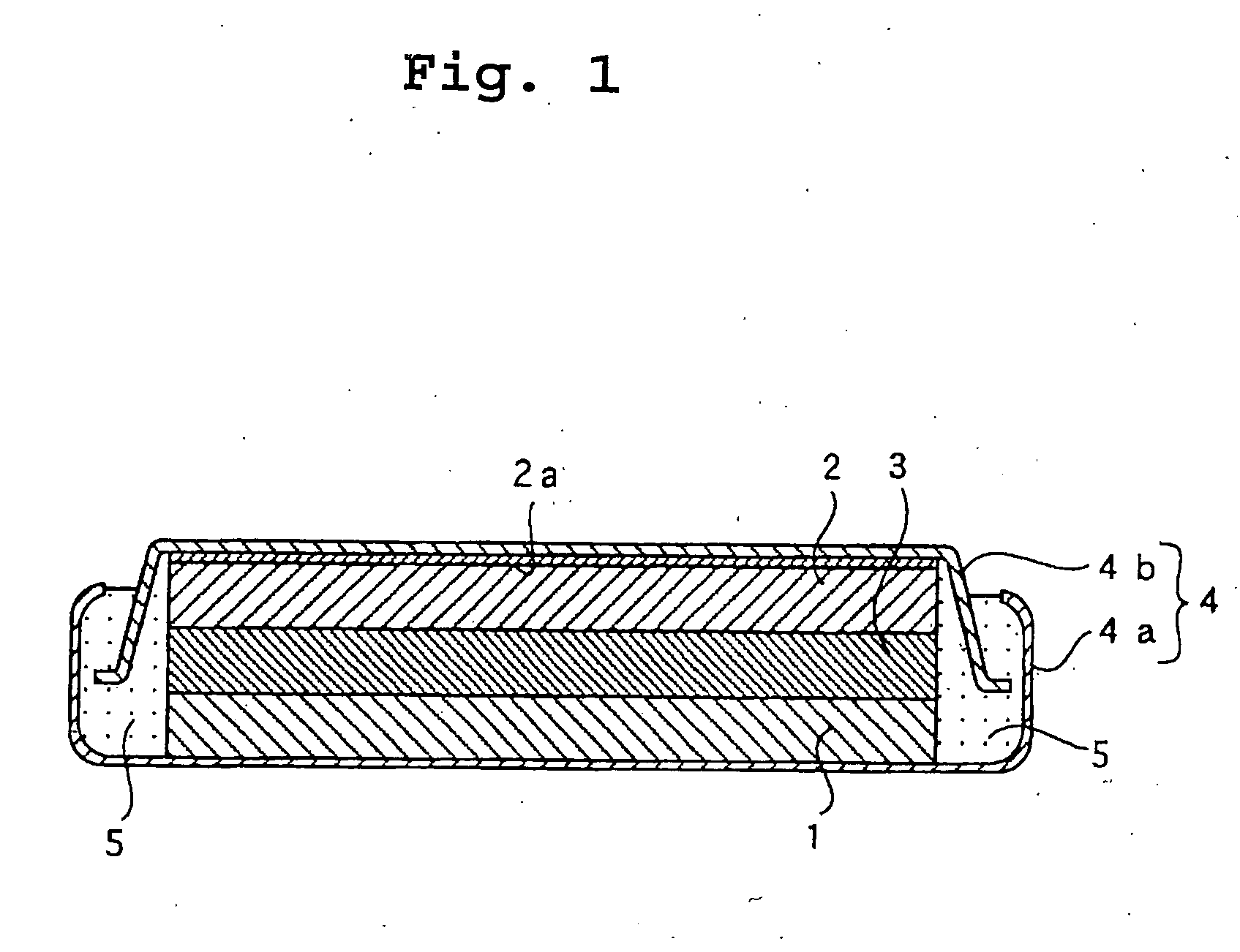

Lithium secondary battery

InactiveUS20040224235A1Improve lithium ion mobilityImprove thermal stabilityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsPhysical chemistrySolvent

A lithium secondary battery including a positive electrode, a negative electrode including a carbon material as an active material, and a nonaqueous electrolyte comprising a solute dissolved in a nonaqueous solvent in which gamma-butyrolactone is the main solvent, wherein the carbon material has a ratio (ID / IG) of a Raman spectrum intensity (a peak intensity ratio) (R) obtained by Raman spectroscopy of 0.2 or greater, and the nonaqueous electrolyte includes at least 0.1 part by weight of vinylene carbonate and at least 0.1 part by weight of vinyl ethylene carbonate in 100 parts by weight of the nonaqueous electrolyte.

Owner:SANYO ELECTRIC CO LTD

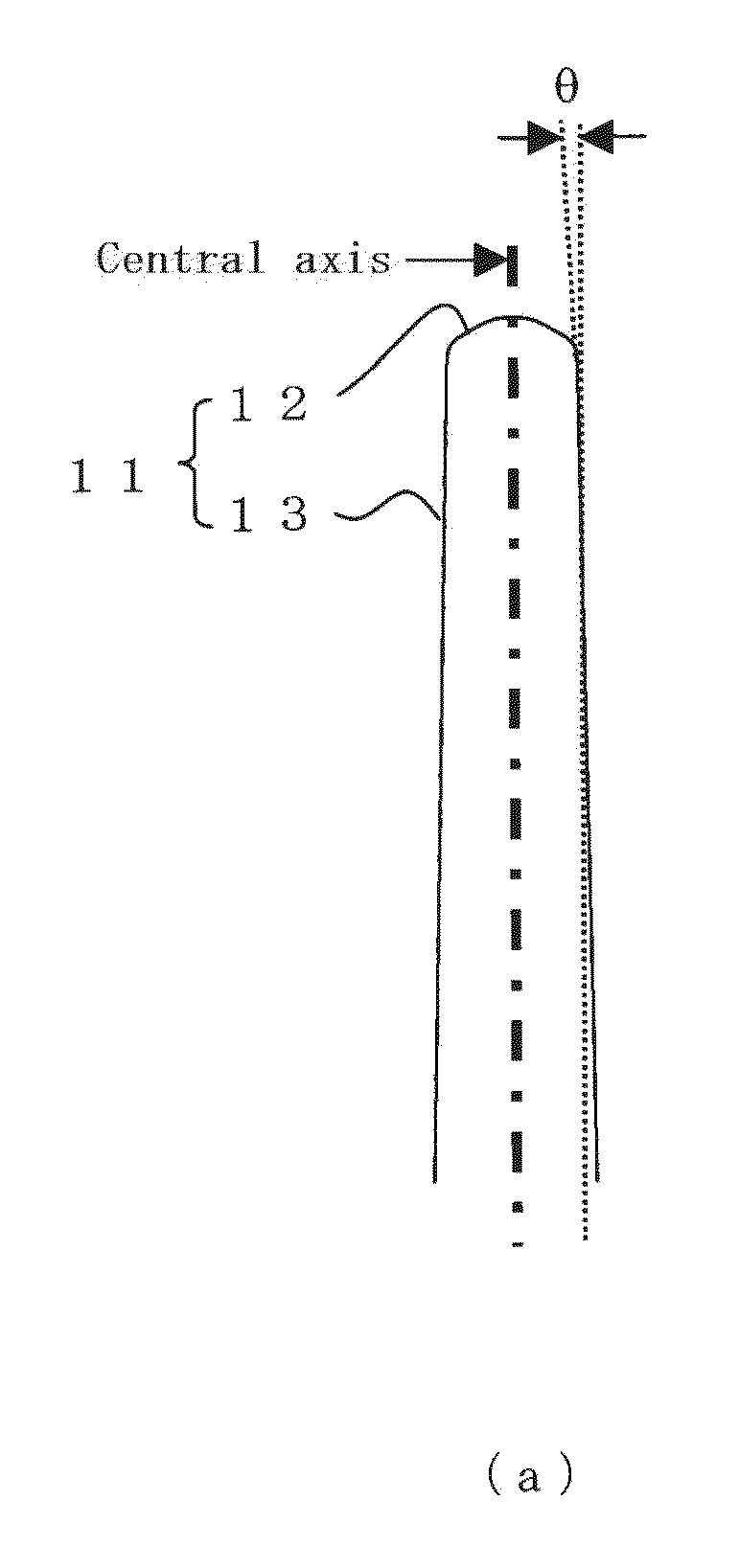

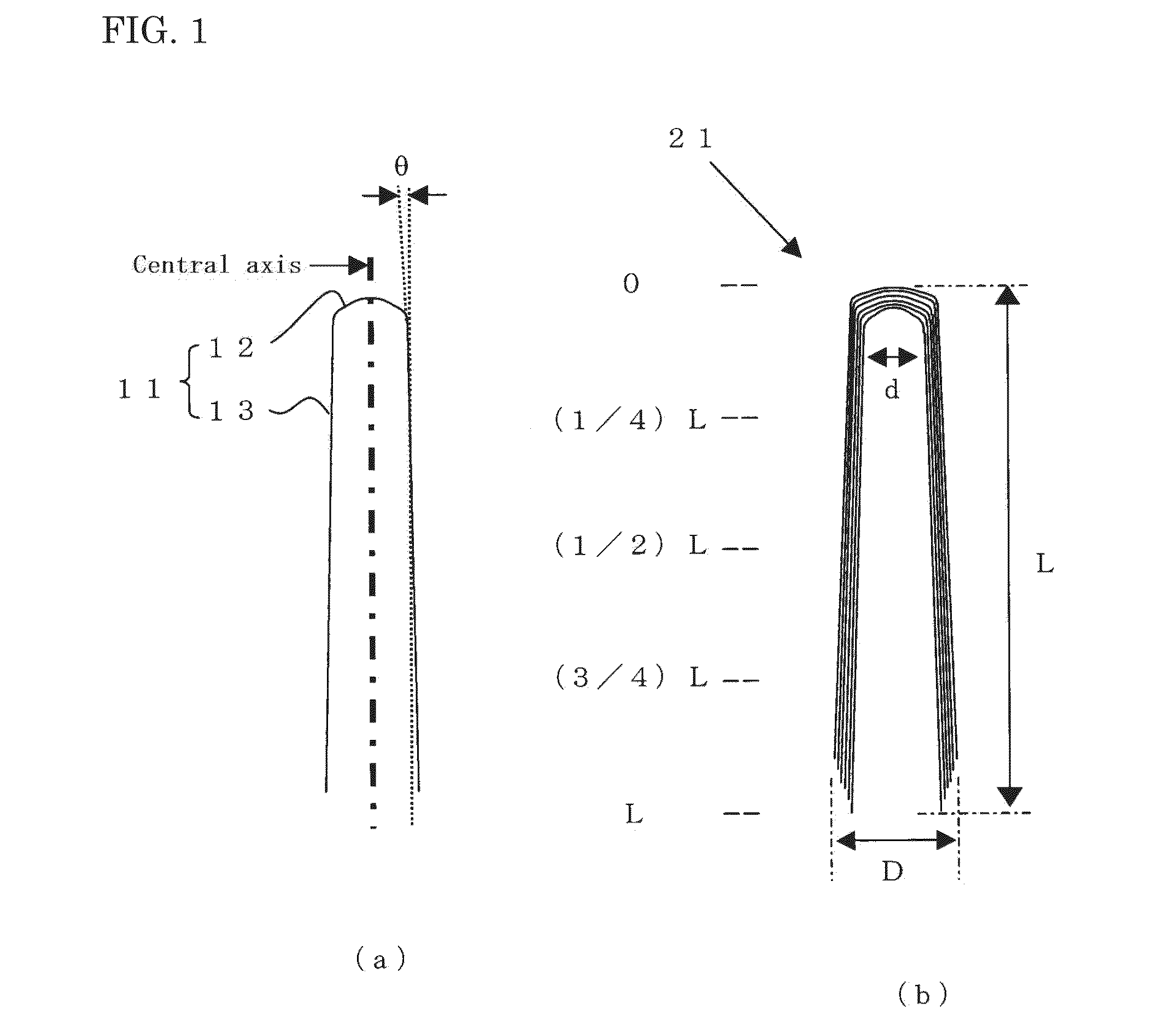

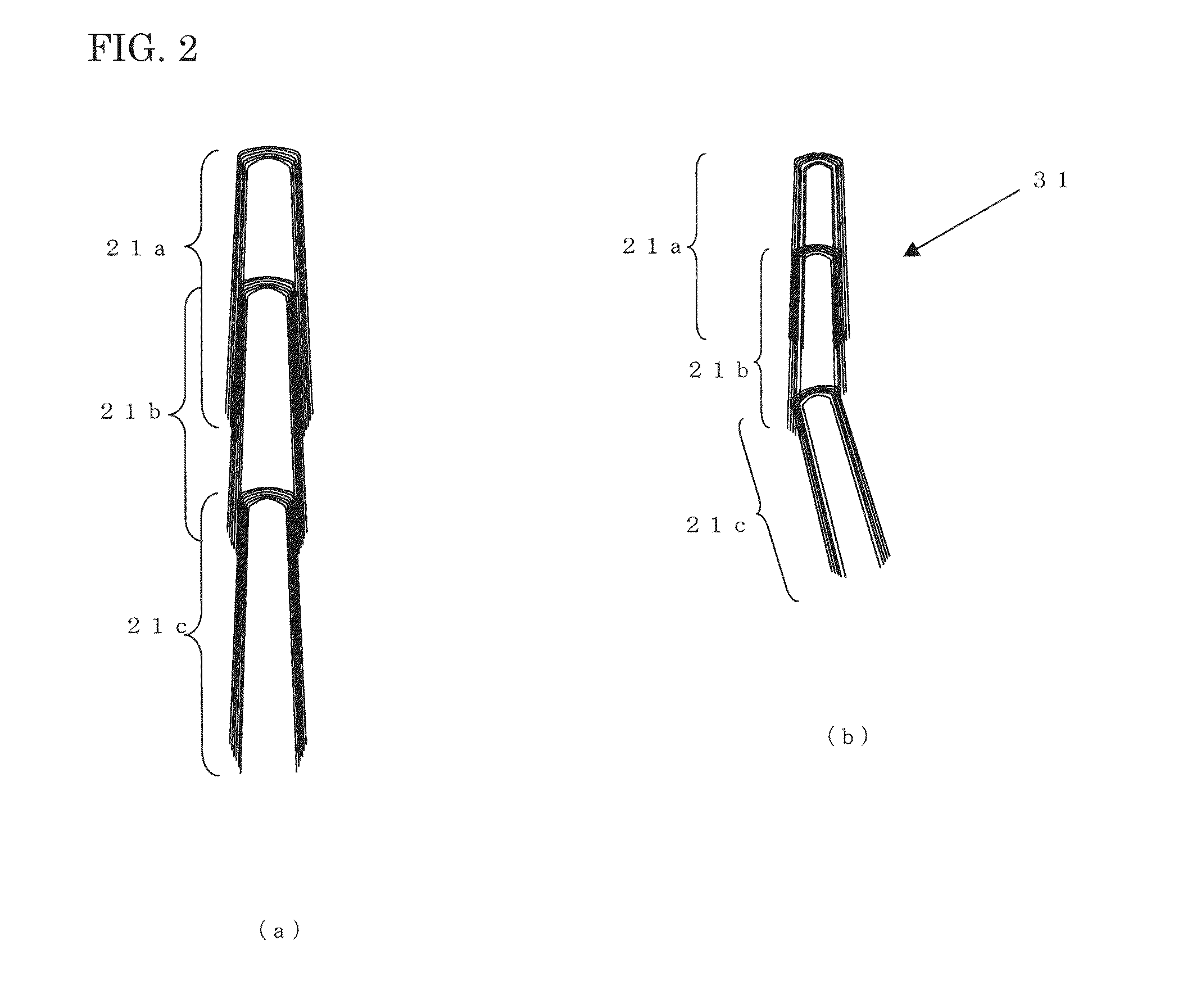

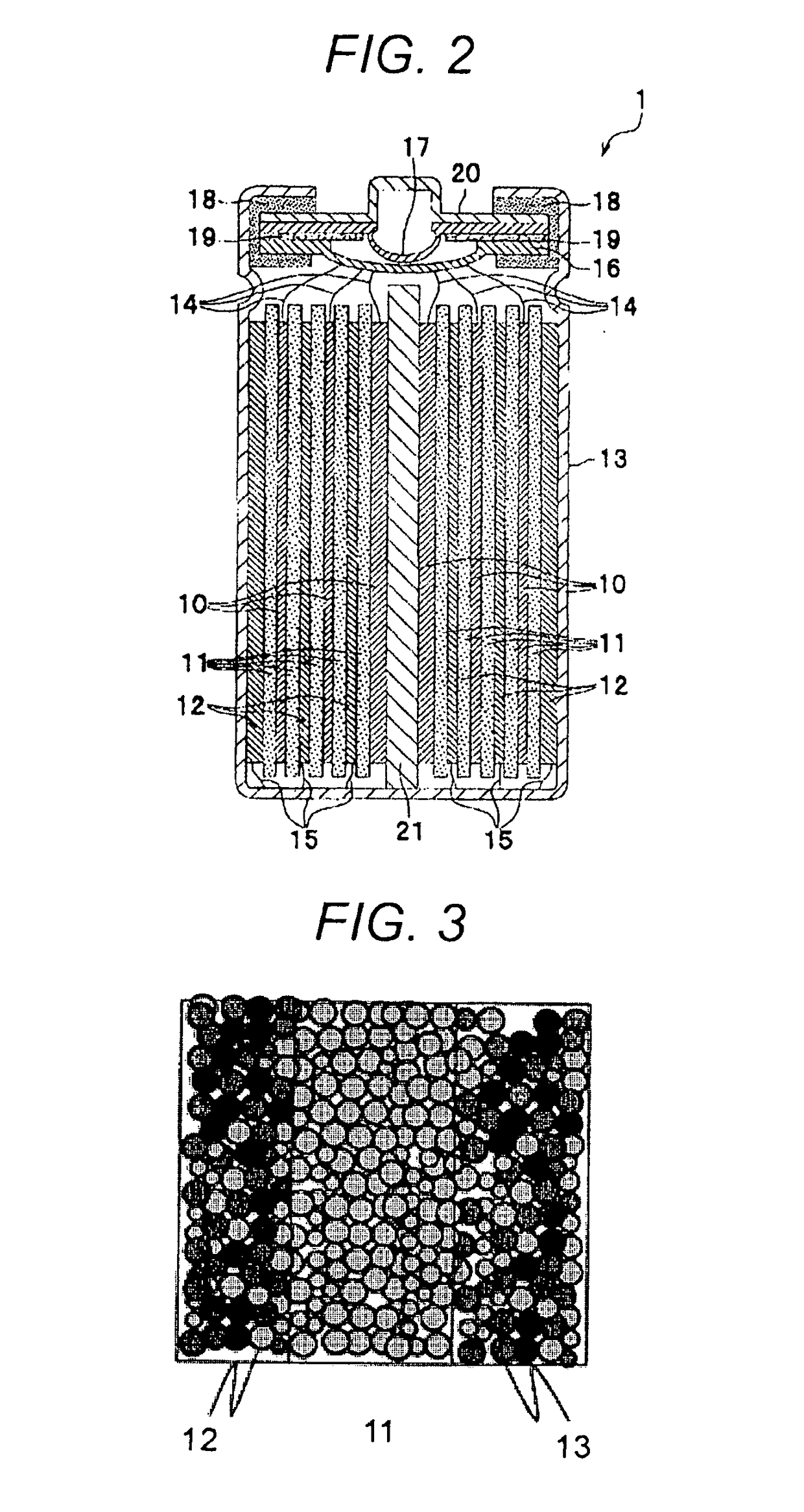

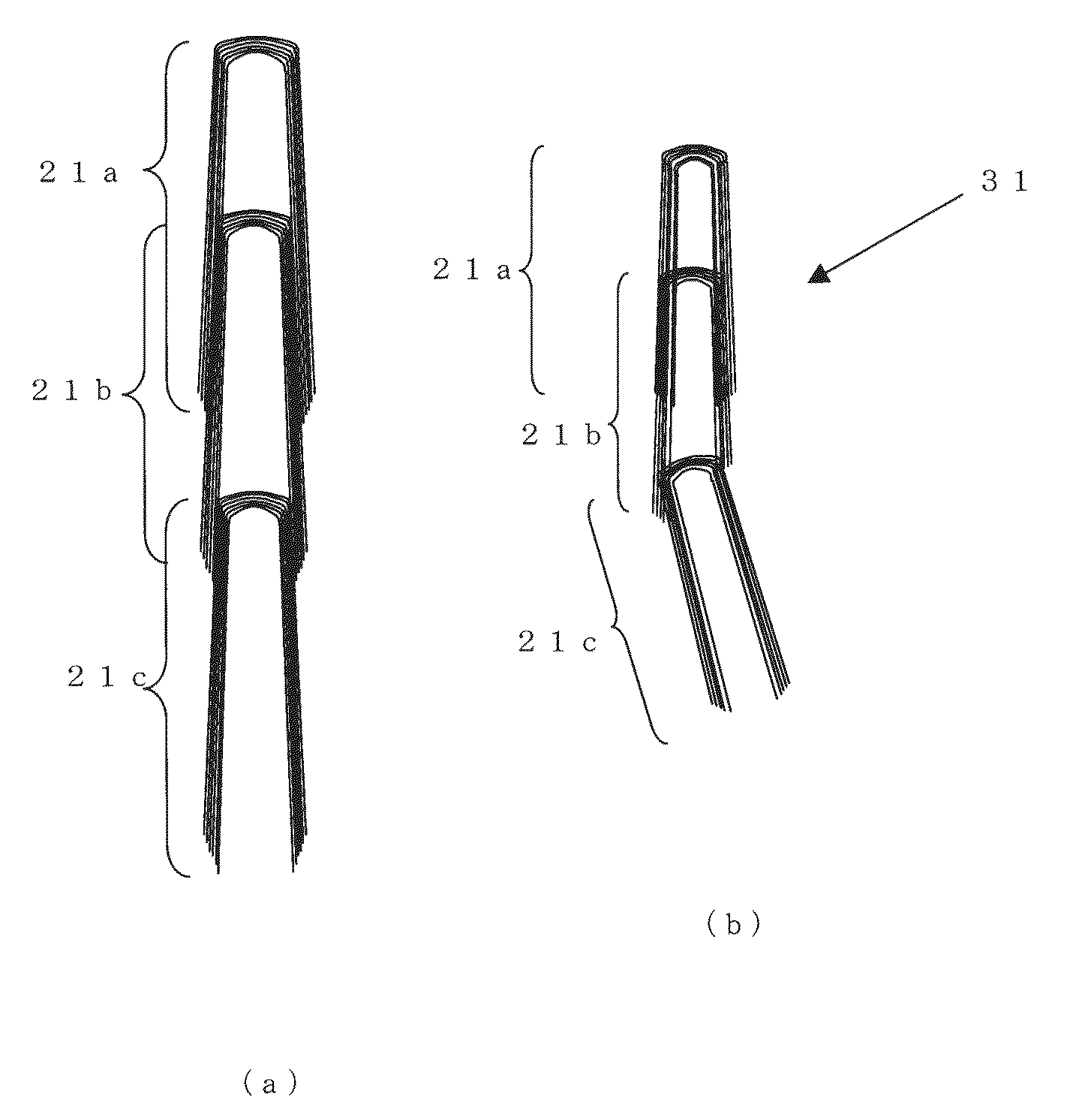

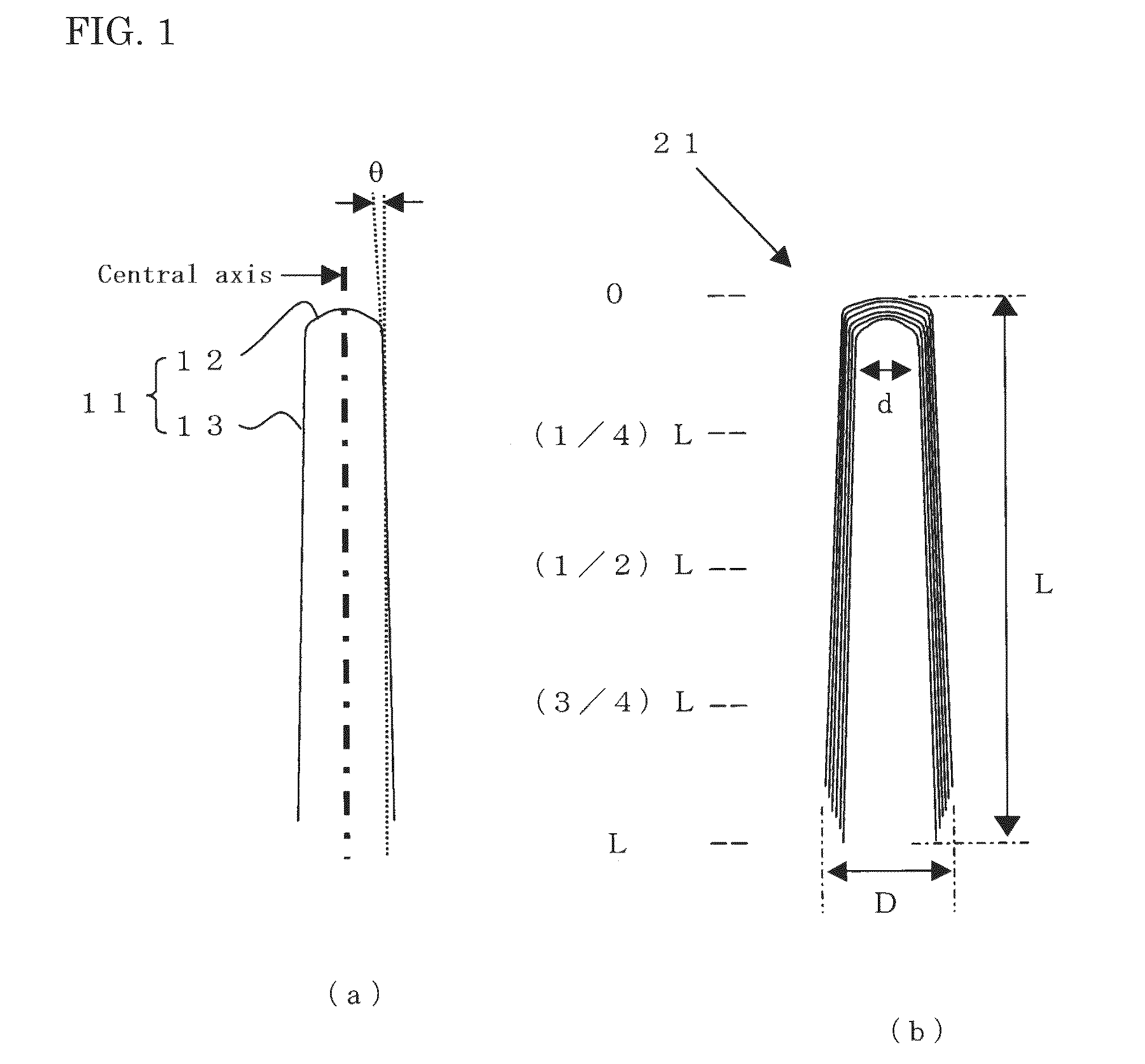

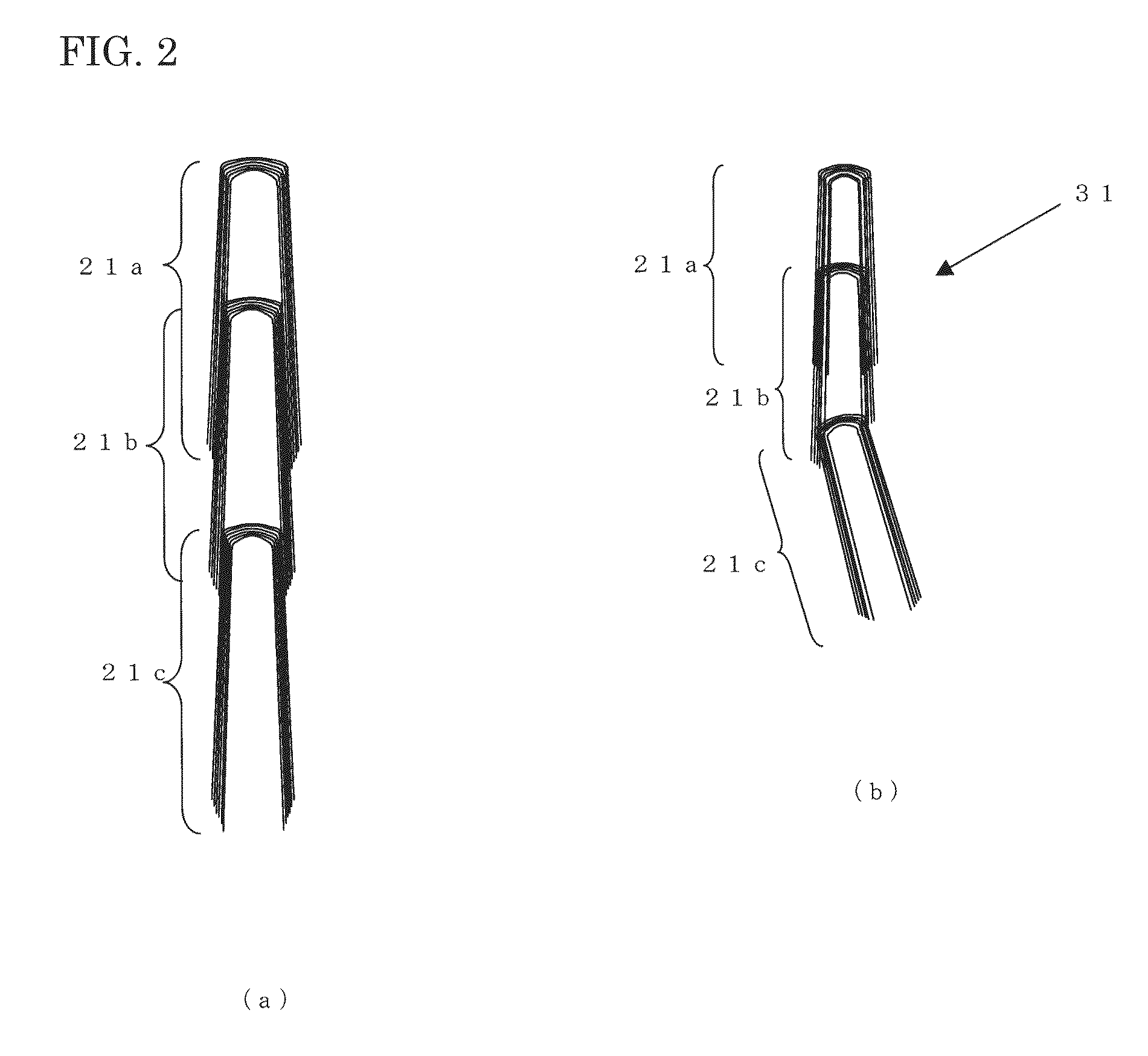

Lithium-titanium complex oxide electrode material conjugated with fine carbon fiber

InactiveUS20130149612A1Improve lithium ion mobilityDeterioration of cyclic propertyFinal product manufactureCeramic shaping apparatusFiberCarbon fibers

The present invention provides an electrode material for a secondary battery wherein the inside and the surface of a lithium-titanium complex oxide is composited with a fine carbon fiber as a network.

Owner:UBE IND LTD

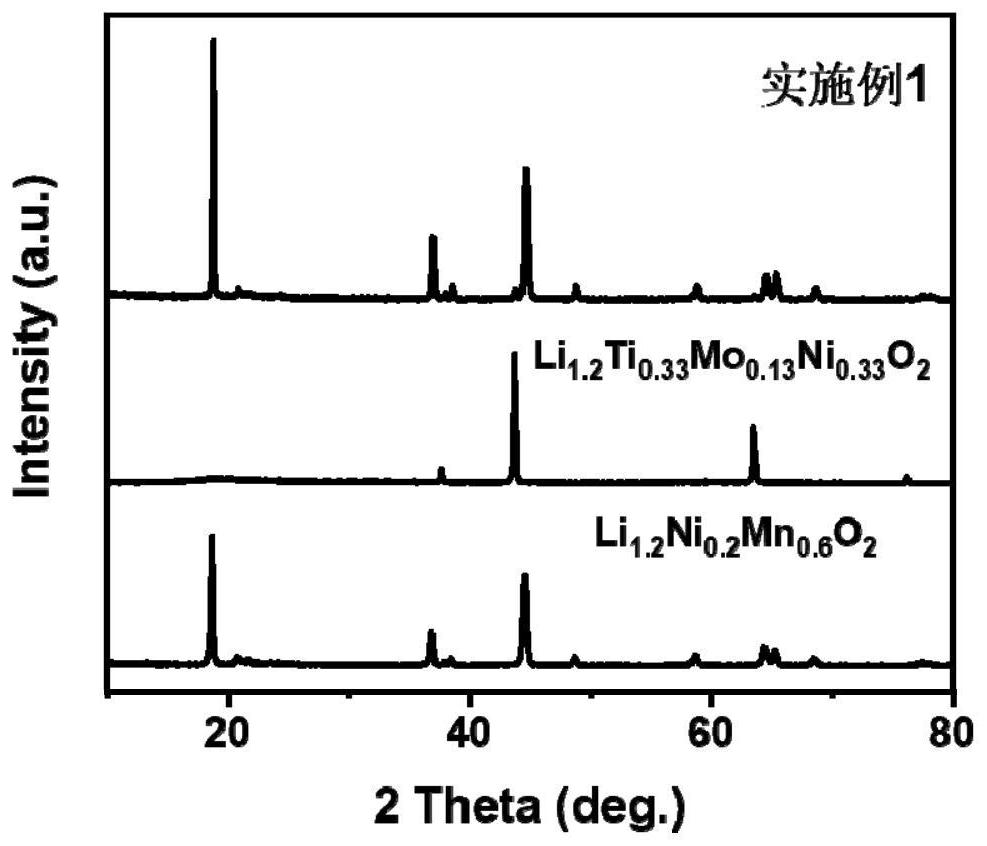

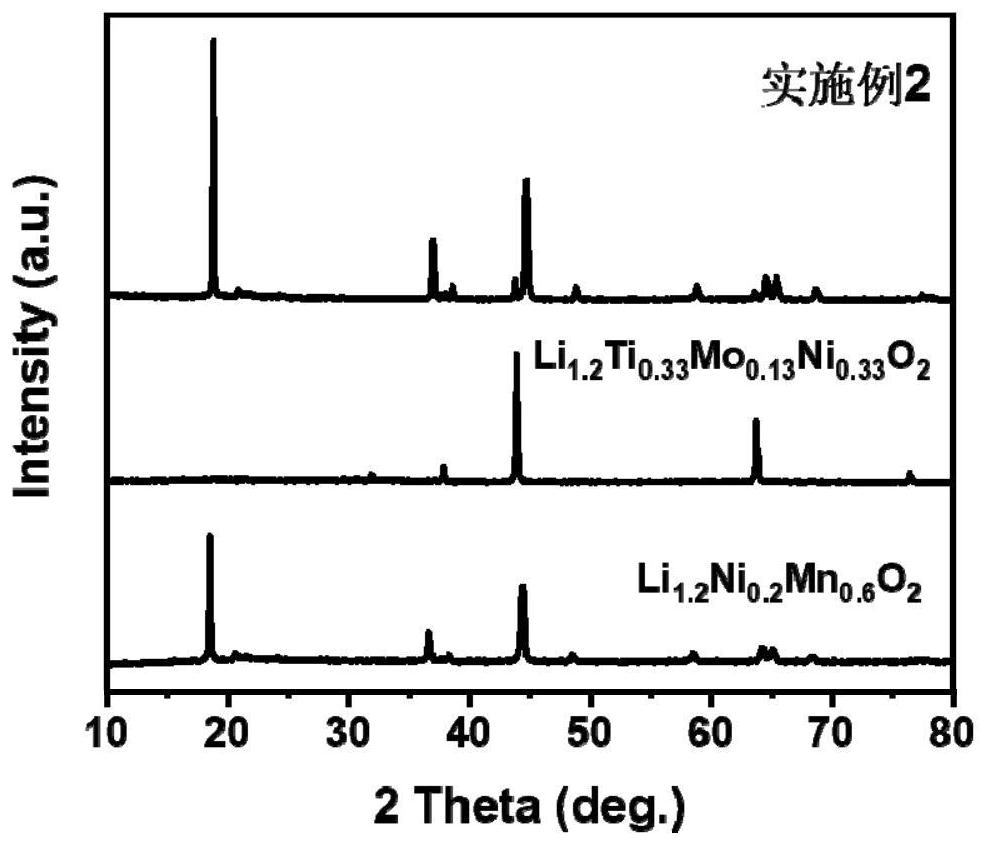

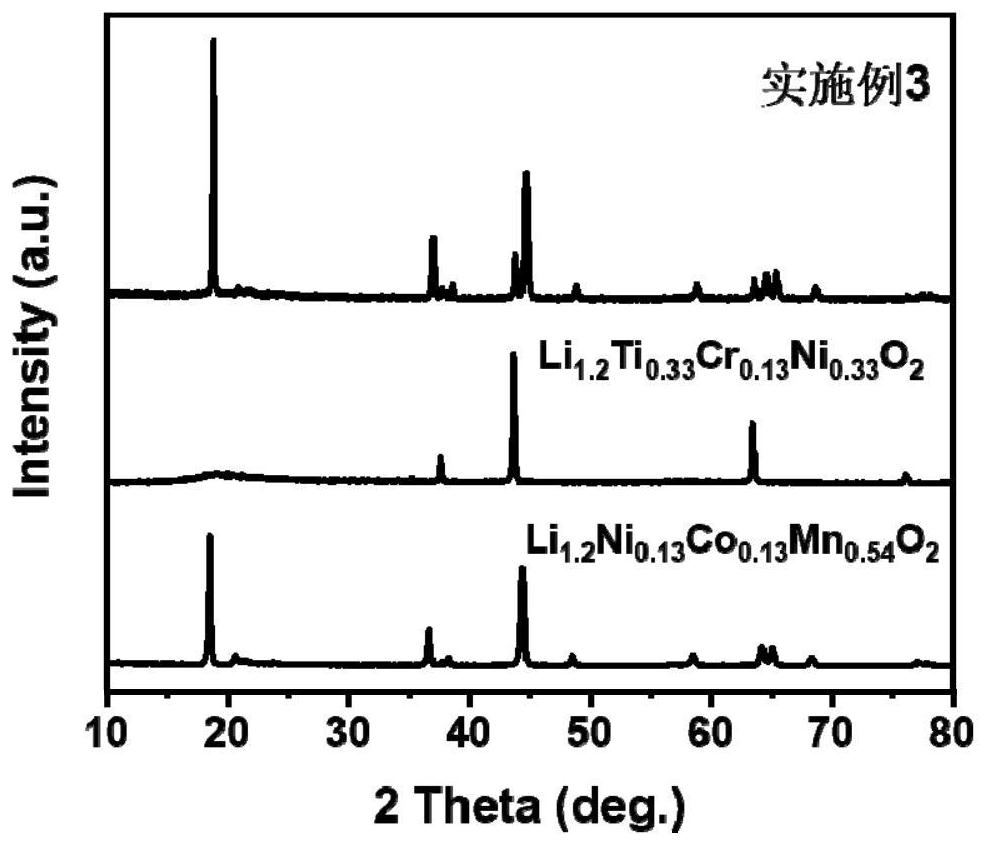

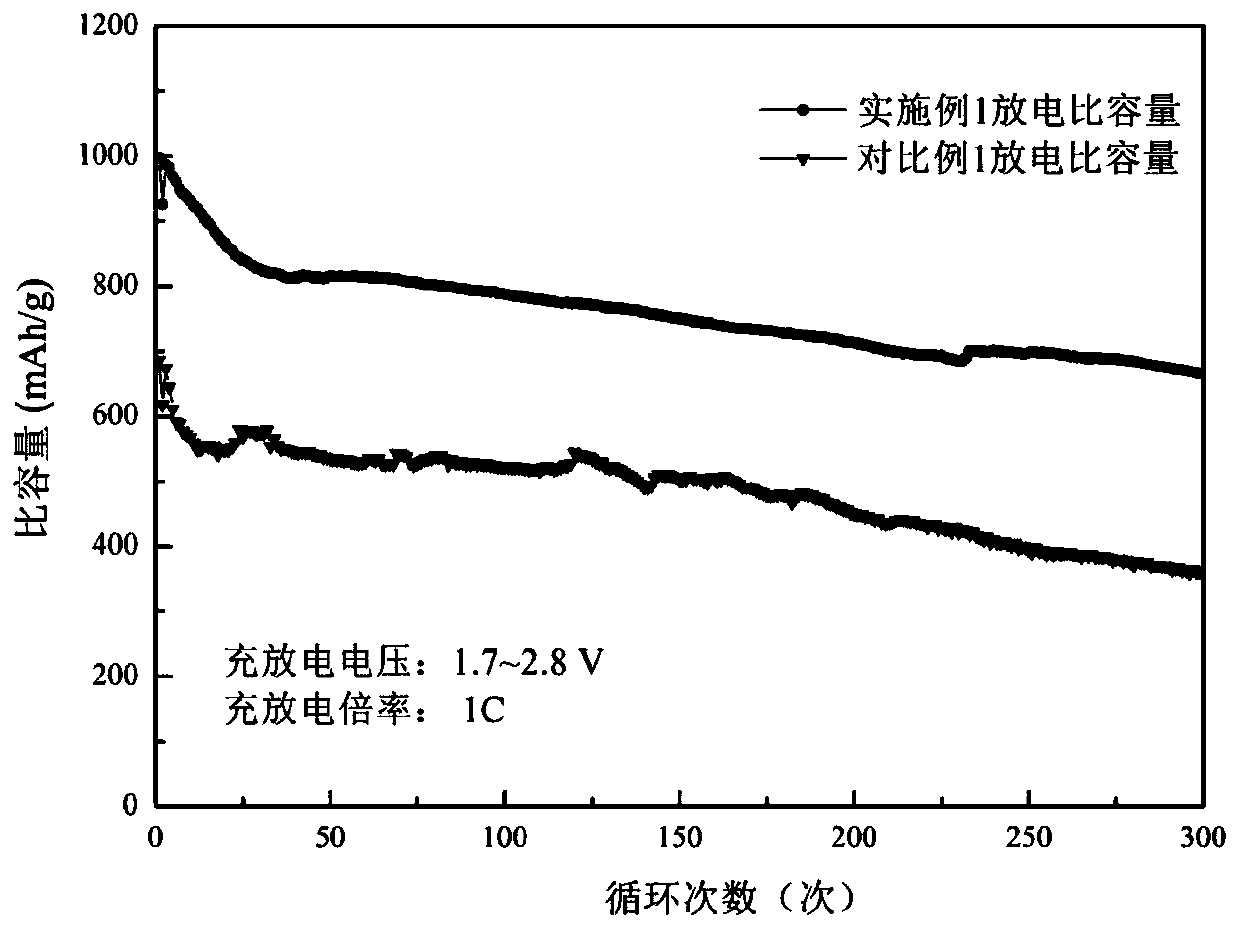

Mixed lithium-rich positive electrode material and preparation method and application thereof

ActiveCN113690414AImprove lithium ion mobilityGood material consistencySecondary cellsPositive electrodesCharge and dischargeLithium

The invention discloses a mixed lithium-rich positive electrode material and a preparation method and application thereof. The mixed lithium-rich positive electrode material is prepared by mixing a layered lithium-rich manganese-based positive electrode material and a lithium-rich disordered rock salt structure positive electrode material, wherein the chemical general formula of the layered lithium-rich manganese-based positive electrode material is xLi2MnO3.(1-x) LiMO2, and x is greater than 0 and less than 1; the chemical general formula of the lithium-rich disordered rock salt structure positive electrode material is Li1 + aTibMcNidO2, wherein 0.1<a<0.3, 0.1<b<0.4, 0.1<c<0.4, 0.2<d<0.4 and a+4b+6c+2d=3. The lithium-rich manganese-based positive electrode material component in the positive electrode material has a typical layered structure, transition metal redox and lattice oxygen redox exist in the charging / discharging process at the same time, and the lithium-rich disordered rock salt structure positive electrode material component has a three-dimensional disordered cation skeleton structure, which can stabilize the oxygen lattices and oxygen variable valence reaction in the lithium-rich oxide positive electrode material, and improve the lithium ion migration capability; the two positive electrode materials generate a specific synergistic effect, advantage complementation is realized, the material consistency is good, the performance is controllable, and the defects in the prior art are overcome.

Owner:北京理工大学重庆创新中心 +1

Surface-coating type lithium nickel manganese oxide material, lithium battery and preparation method thereof

InactiveCN106099084ASmall and uniform particle sizeImprove electrochemical performanceCell electrodesSecondary cellsDivalent metal ionsManganese oxide

The invention discloses a surface-coating type lithium nickel manganese oxide material, a lithium battery and a preparation method thereof. The surface-coating type lithium nickel manganese oxide material is characterized in that the surface of LiNi0.5Mn1.5O4 is coated with LiM0.5Mn1.5O4 with spinel structure, wherein M is positive bivalent metal ion. The surface-coating type lithium nickel manganese oxide material is characterized in that the particle size is small and uniform, and the electro-chemical property of LiNi0.5Mn1.5O4 is favorably improved; the surface of the prepared material is coated with LiM0.5Mn1.5O4 with electro-chemical inactivity, so that the good lithium ion transfer rate and good structure stability of LiNi0.5Mn1.5O4 are guaranteed in the charging and discharging process, and the side reaction of LiNi0.5Mn1.5O4 and electrolyte is inhibited. The preparation method has the advantages that the operation is simple, the preparation is convenient, and the cost is low; the significance on promoting the application and development of LiNi0.5Mn1.5O4 positive electrode material is realized.

Owner:SICHUAN JIANXING LITHIUM BATTERY

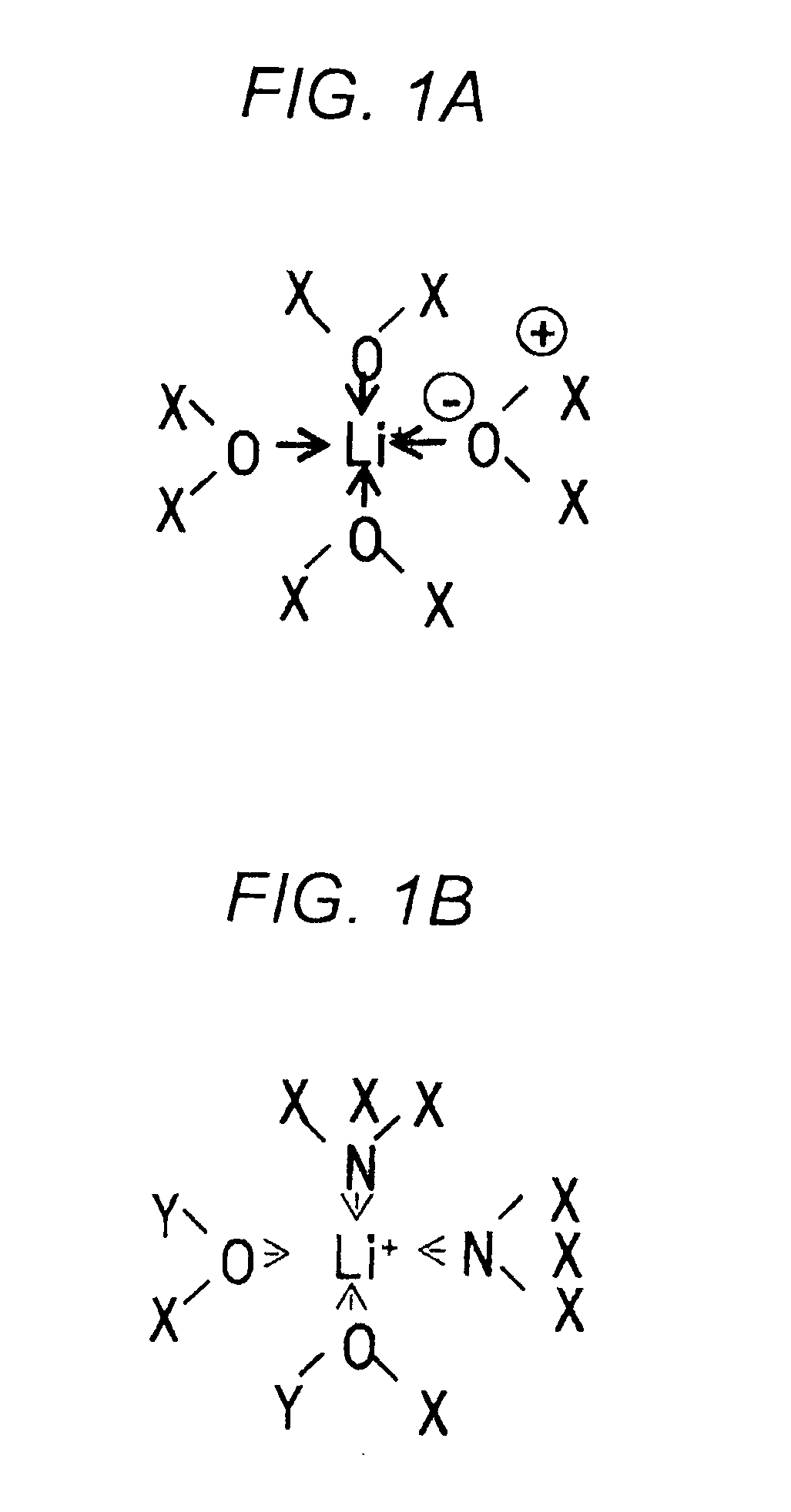

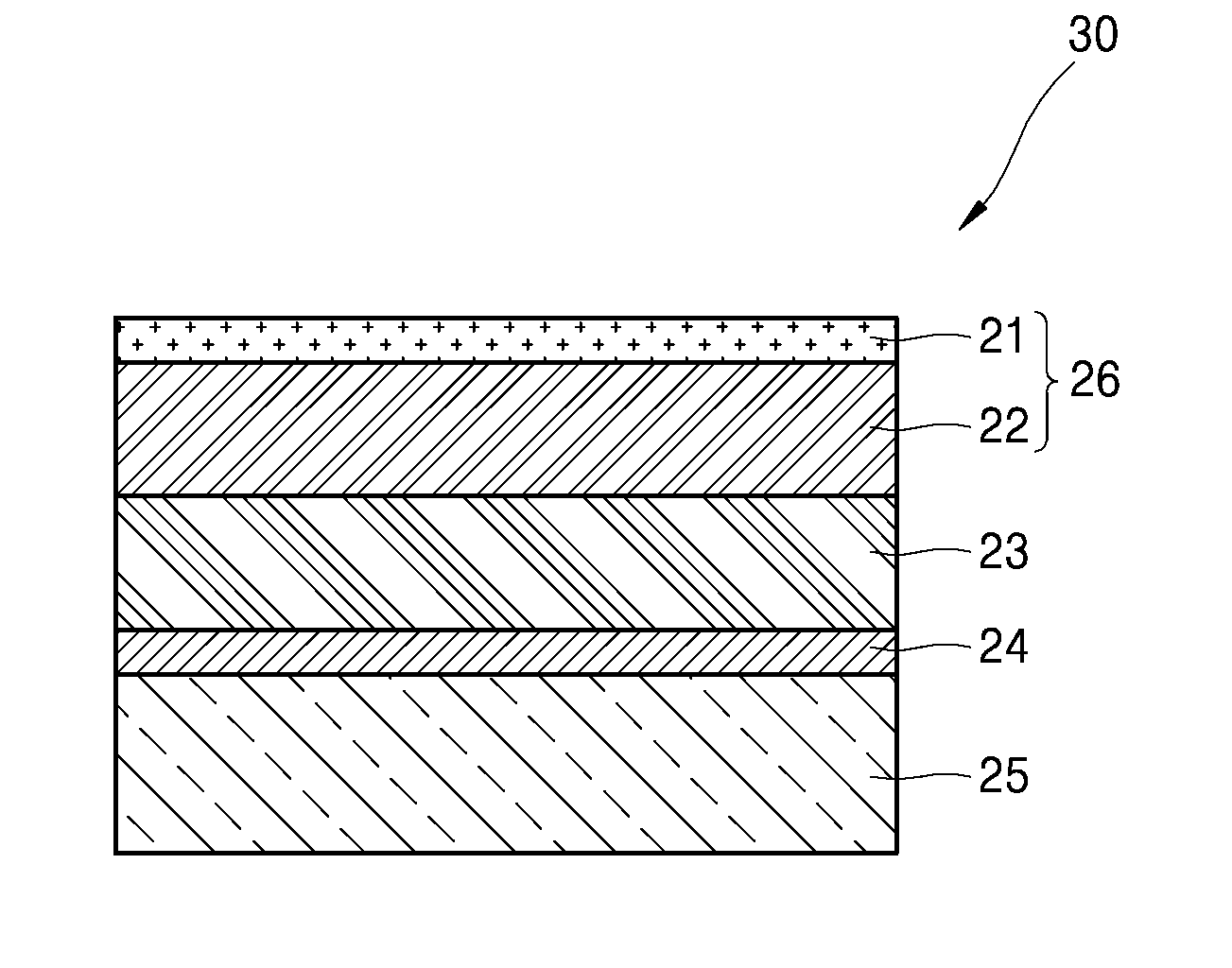

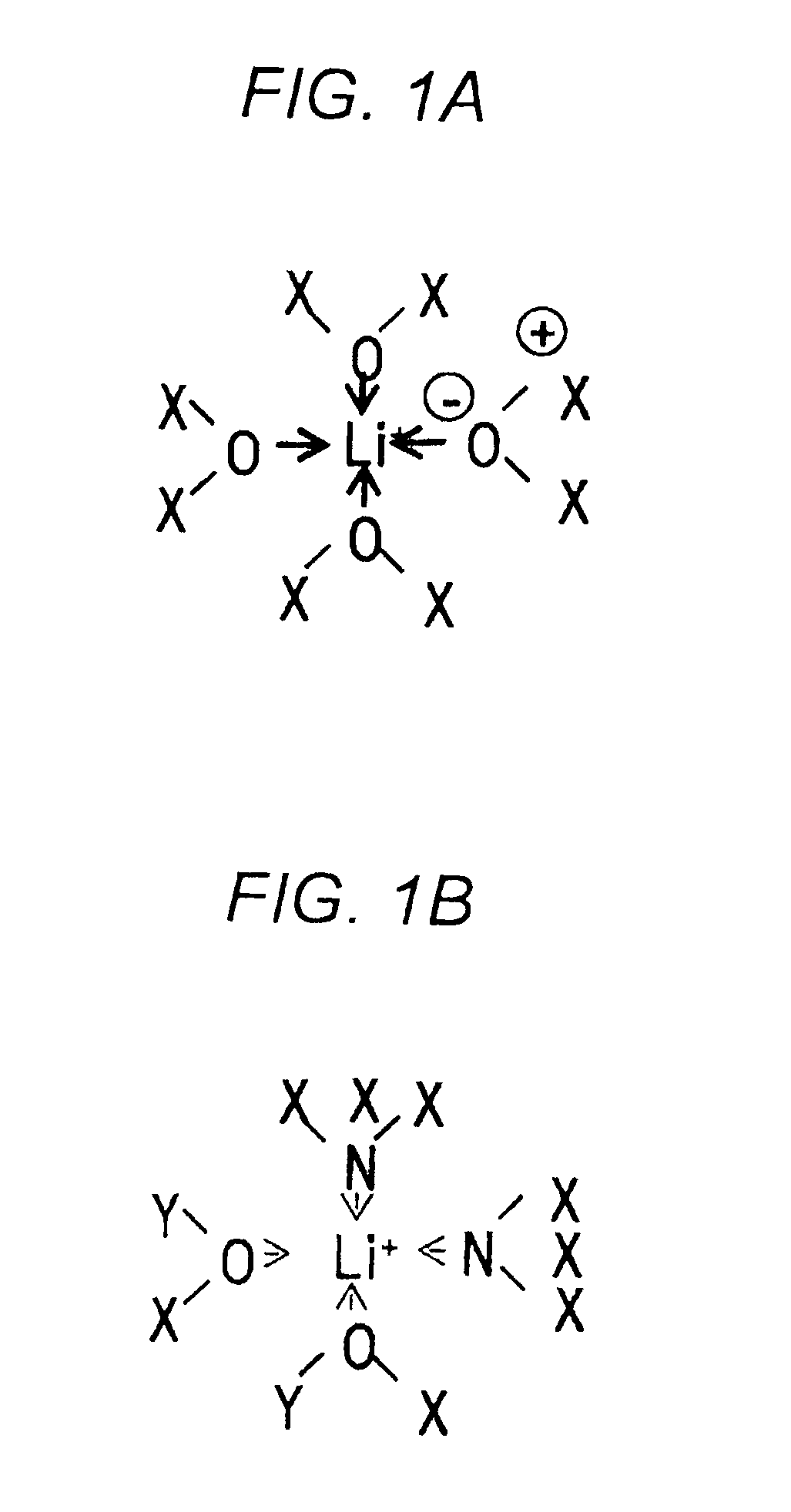

Composite electrolyte, protective film including composite electrolyte, protected negative electrode including the protective film, and lithium metal battery including the protected negative electrode

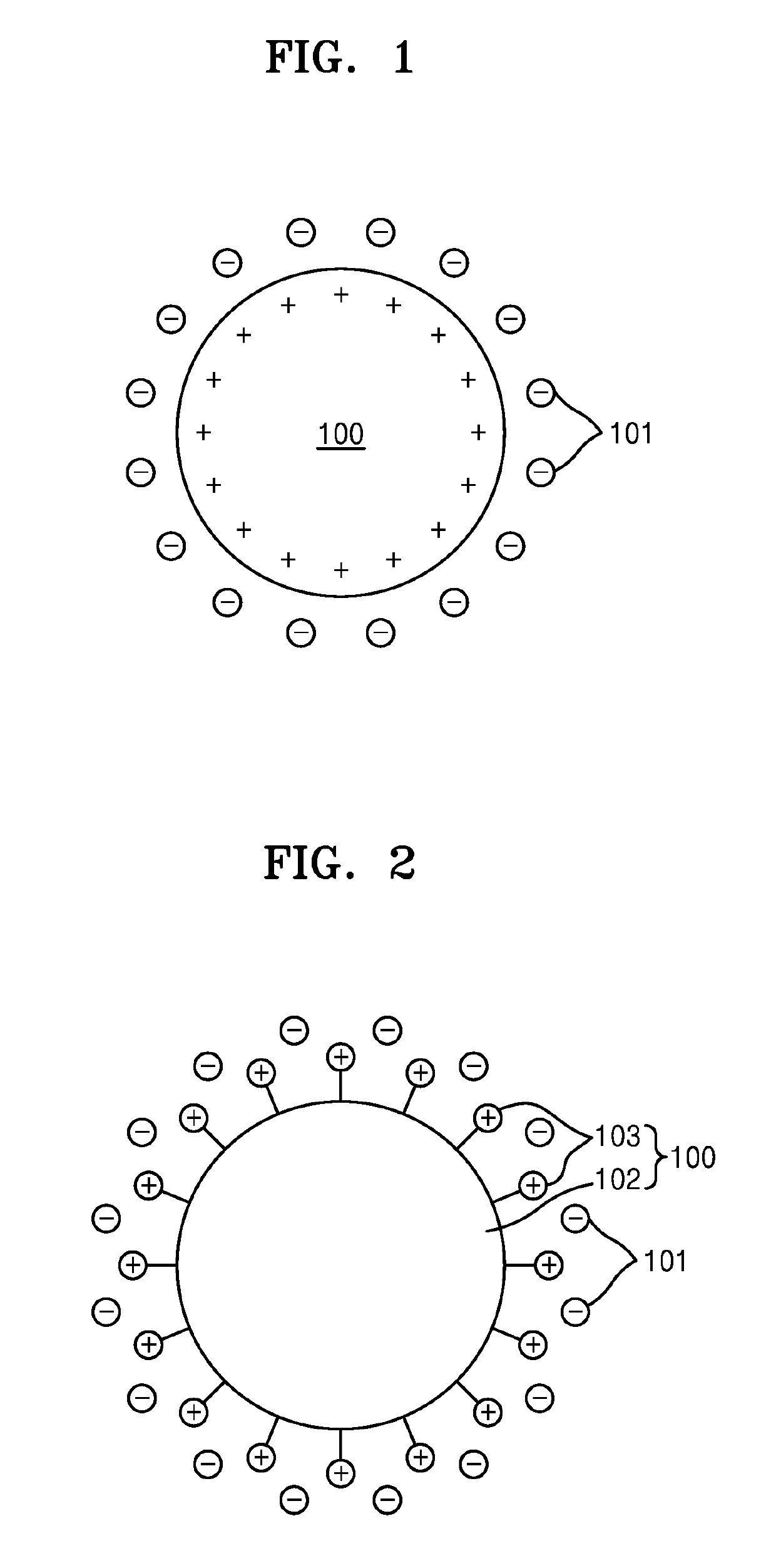

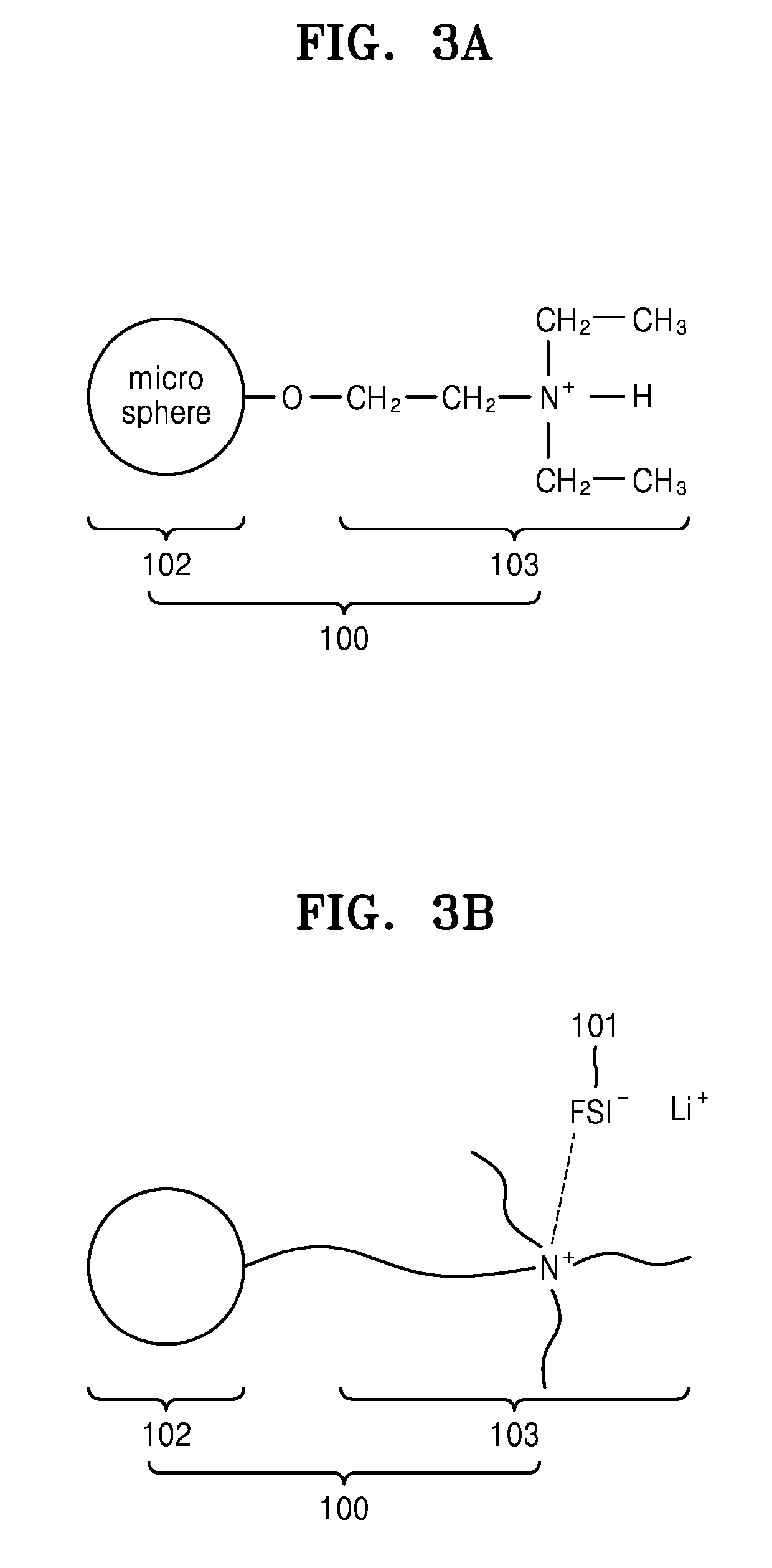

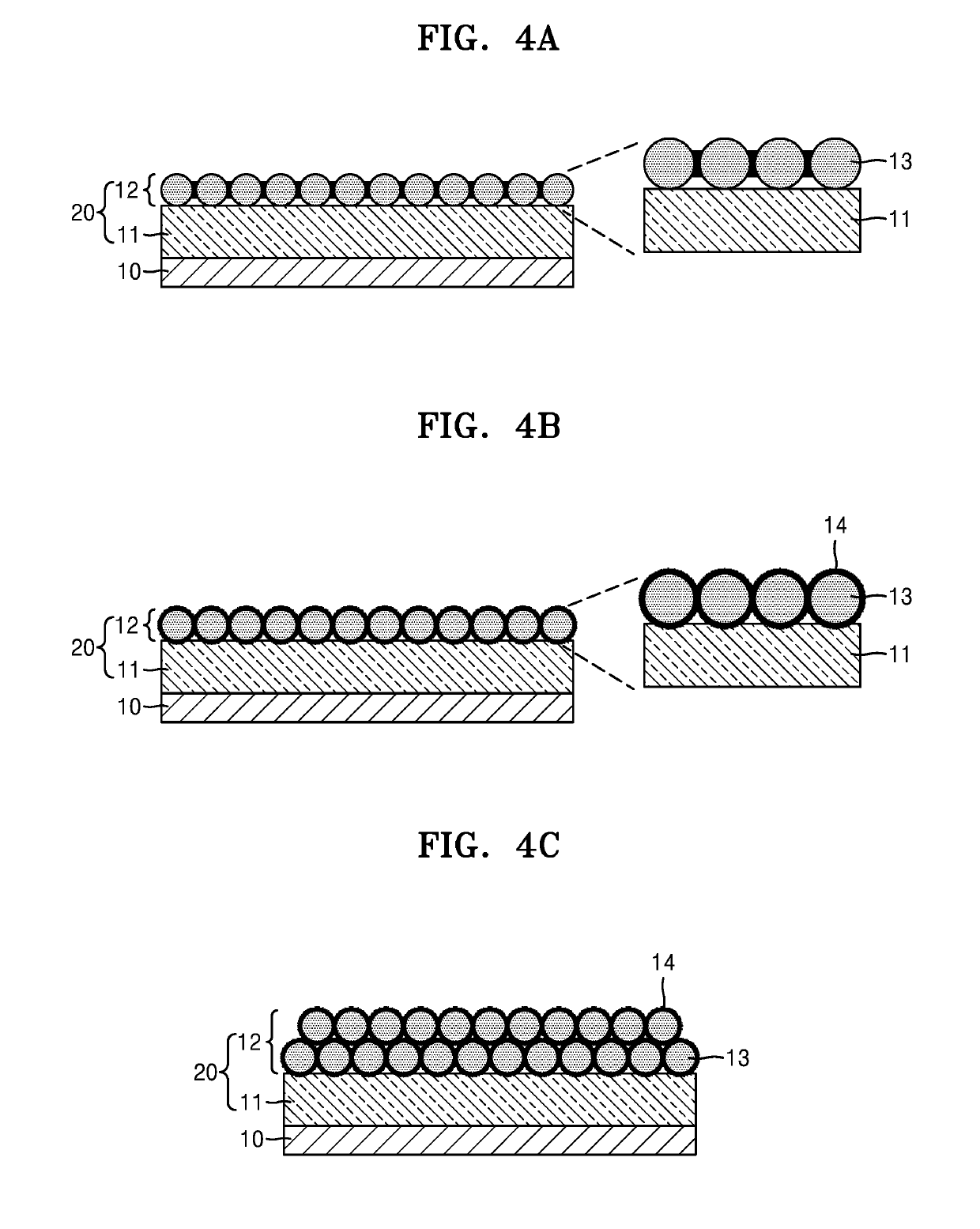

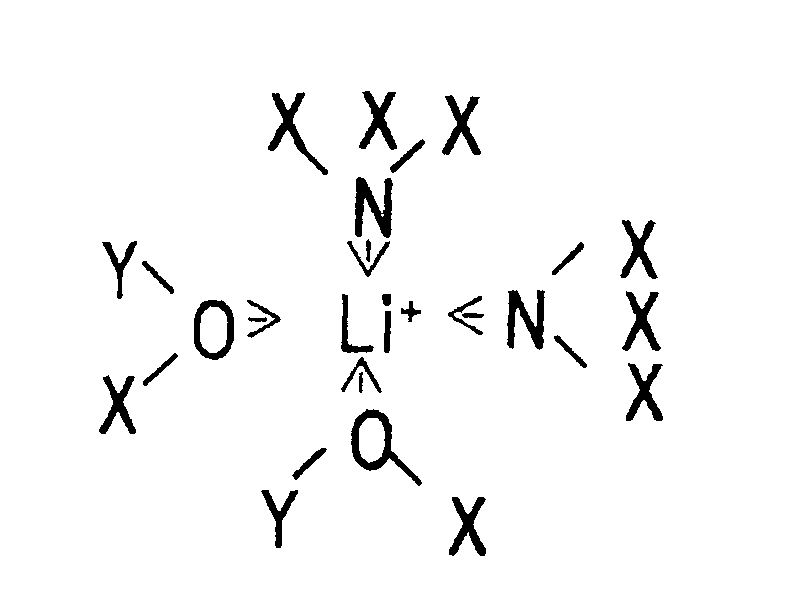

ActiveUS20190181435A1Improve lithium ion mobilityInhibit side effectsSolid electrolytesConductive materialComposite electrolyteLithium metal

A composite electrolyte includes: a positively charged particle, a particle that is positively charged by having a coordinate bond with a cation, or a combination thereof; and a lithium salt.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Solid electrolyte and all-solid state lithium ion secondary battery

InactiveUS9853322B2High electronegativityImprove lithium ion mobilityFinal product manufactureElectrolytesAll solid statePhysical chemistry

In a Li ion conductivity oxide solid electrolyte containing lithium, lanthanum, and zirconium, a part of oxygen is substituted by an element M (M=N, Cl, S, Se, or Te) having smaller electronegativity than oxygen.

Owner:HITACHI LTD

Lithium—titanium complex oxide electrode material conjugated with fine carbon fiber

InactiveUS9190660B2Improve lithium ion mobilityDeterioration of cyclic propertyFinal product manufactureActive material electrodesFiberLithium

The present invention provides an electrode material for a secondary battery wherein the inside and the surface of a lithium-titanium complex oxide is composited with a fine carbon fiber as a network.

Owner:UBE IND LTD

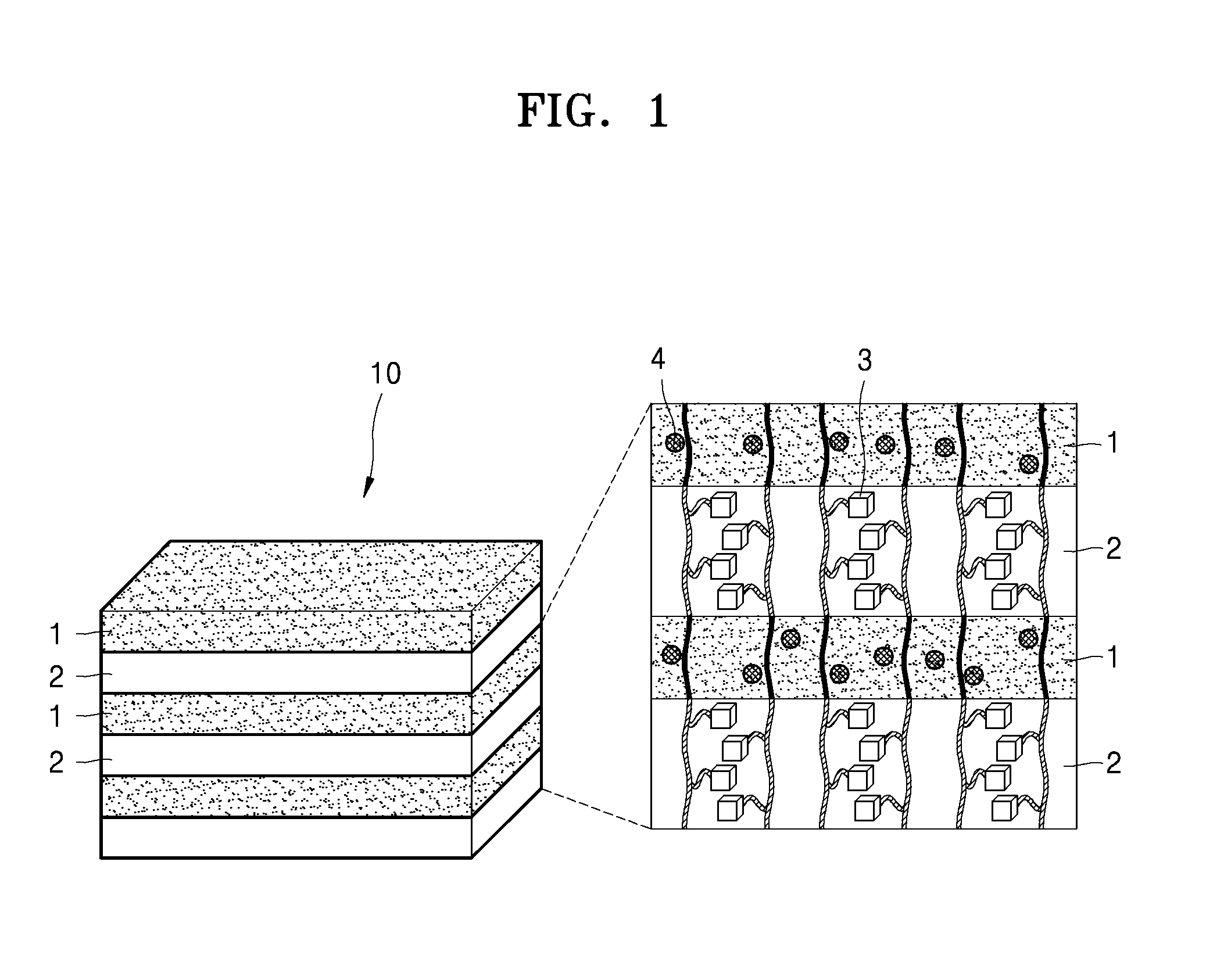

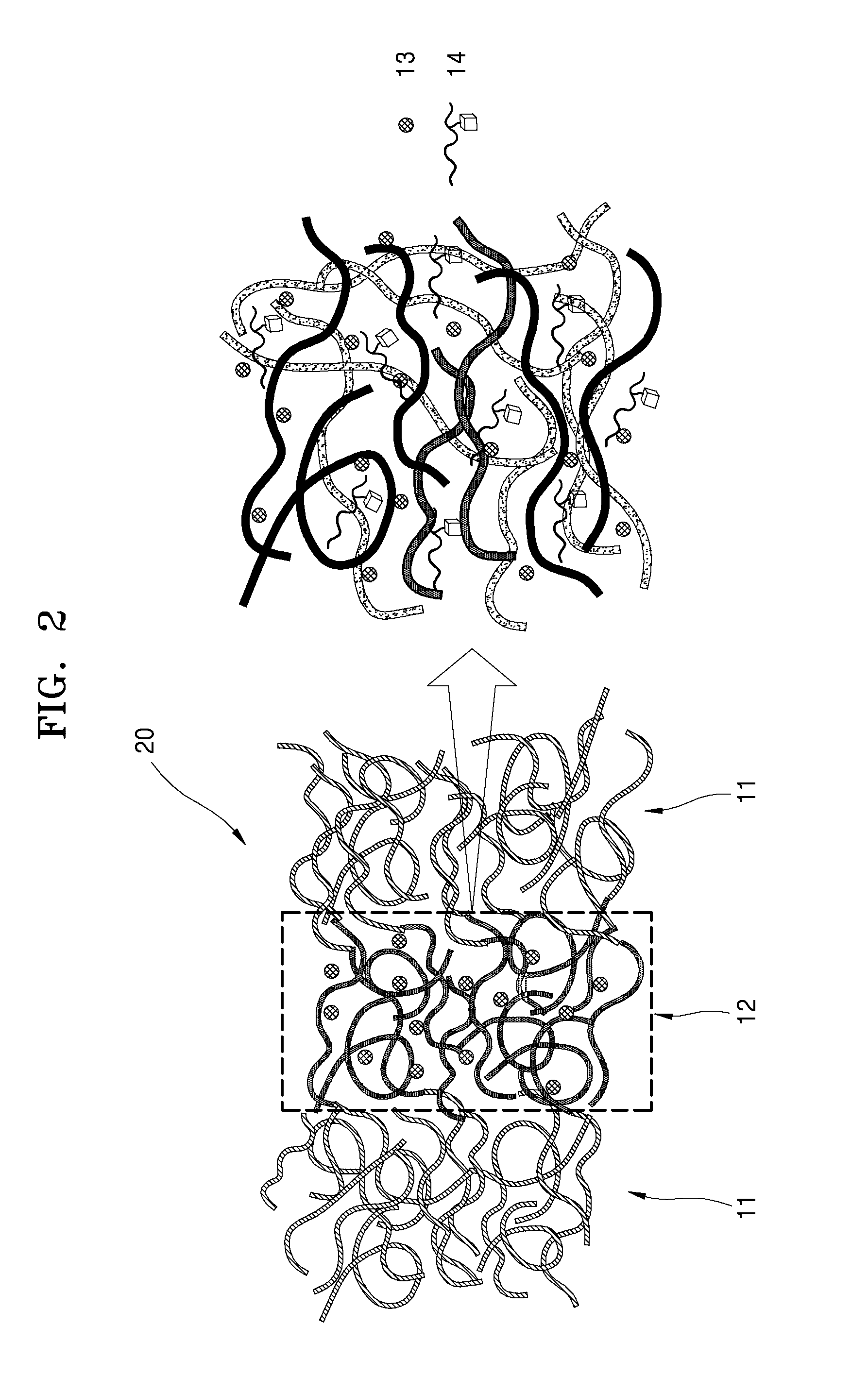

Composite solid electrolyte, method of preparing composite solid electrolyte, and electrochemical battery including composite solid electrolyte

PendingUS20210249655A1Improve lithium ion mobilityImprove battery performanceSolid electrolytesNegative electrodesNano structuringPhysical chemistry

A composite solid electrolyte including: a porous nanostructure; and a solid electrolyte disposed on a surface of the porous nanostructure, wherein the composite solid electrolyte satisfies Equation 10<TSE / D<4 Equation 1wherein TSE is a thickness of the solid electrolyte, and D is an average diameter of pores of the porous nanostructure.

Owner:SAMSUNG ELECTRONICS CO LTD

Solid polymer electrolyte and lithium secondary batttery including same

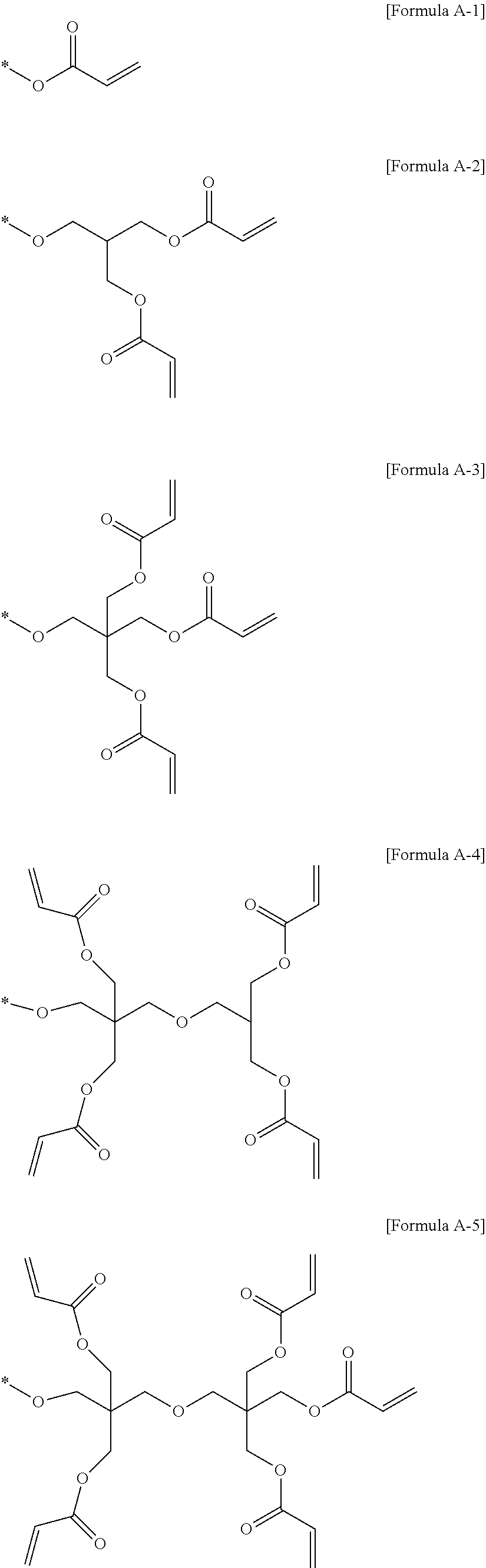

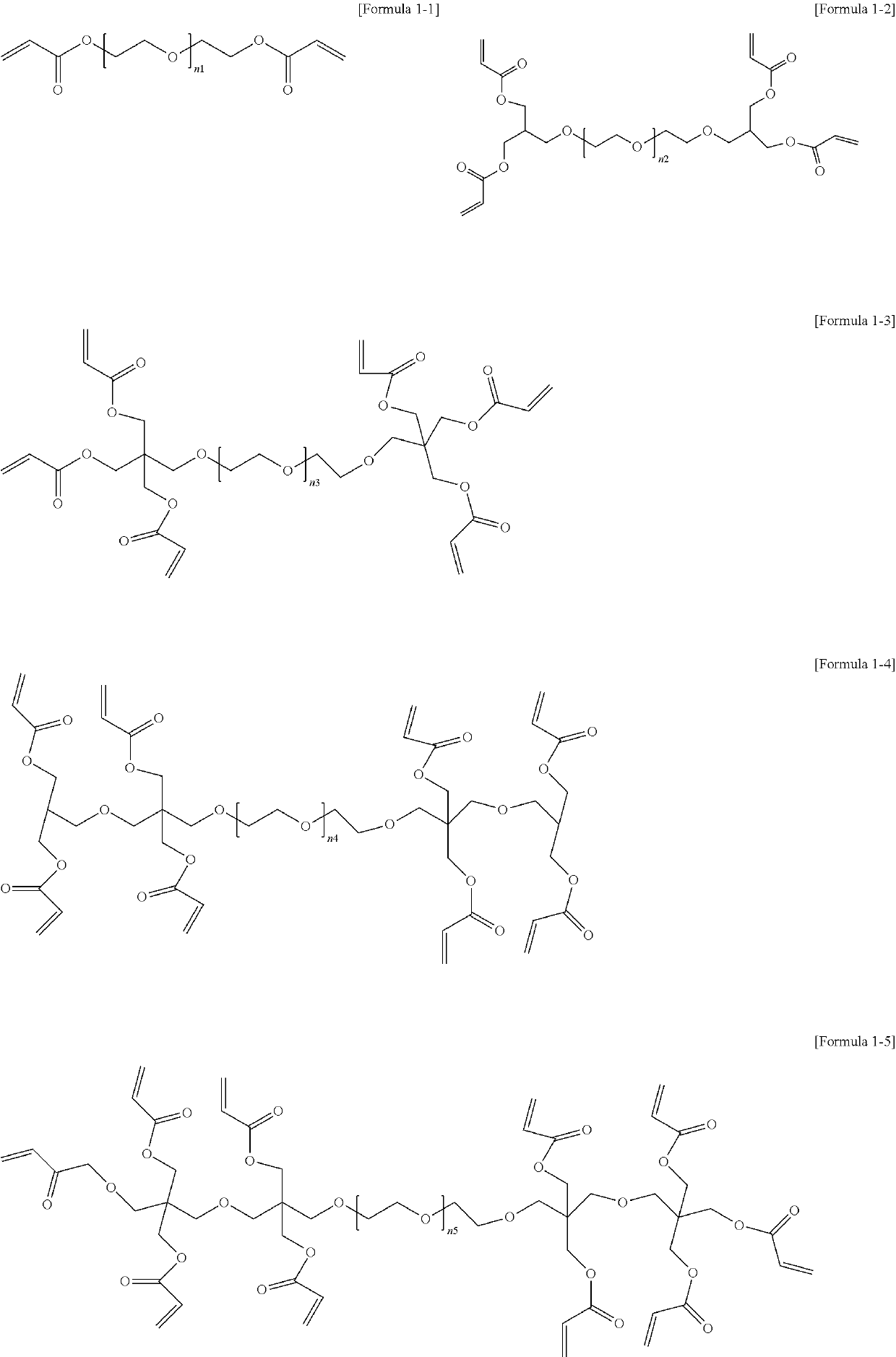

ActiveUS20200373615A1Improve ionic conductivityEnhanced couplingSolid electrolytesLi-accumulatorsMethacrylatePorous substrate

The present invention relates to a solid polymer electrolyte including a porous substrate formed of an inorganic fiber containing an ethylenically unsaturated group, a polymer compound coupled to the inorganic fiber and including a polymer network in which an oligomer containing a (meth)acrylate group is coupled in a three-dimensional structure, and a lithium salt, and to a lithium secondary battery including the same.

Owner:LG ENERGY SOLUTION LTD

Lithium ion-conducting garnet-like compounds

ActiveUS9761905B2Improve stabilityImprove lithium ion mobilityTantalum compoundsZirconium compoundsLithiumCompound a

A lithium ion-conducting compound, having a garnet-like crystal structure, and having the general formula: Lin[A(3-a′-a″)A′(a′)A″(a″)][B(2-b′-b″)B′(b′)B″(b″)][C′(c′)C″(c″)]O12, where A, A′, A″ stand for a dodecahedral position of the crystal structure, where A stands for La, Y, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm and / or Yb, A′ stands for Ca, Sr and / or Ba, A″ stands for Na and / or K, 0<a′<2 and 0<a″<1, where B, B′, B″ stand for an octahedral position of the crystal structure, where B stands for Zr, Hf and / or Sn, B′ stands for Ta, Nb, Sb and / or Bi, B″ stands for at least one element selected from the group including Te, W and Mo, 0<b′<2 and 0<b″<2, where C and C″ stand for a tetrahedral position of the crystal structure, where C stands for Al and Ga, C″ stands for Si and / or Ge, 0<c′<0.5 and 0<c″<0.4, and where n=7+a′+2·a″−b′−2·b″−3·c′−4·c″ and 5.5<n<6.875.

Owner:ROBERT BOSCH GMBH

Organic-inorganic silicon structure-containing block copolymer, electrolyte including the same, and lithium battery including the electrolyte

ActiveUS9786950B2Improve ionic conductivityImprove lithium ion mobilitySolid electrolytesConductive materialPolymer scienceSide chain

An organic-inorganic silicon structure-containing block copolymer including a first domain including an ion conductive polymer block; and a second domain including a polymer block including a non-conducting polymer and an organic-inorganic silicon structure, wherein the organic-inorganic silicon structure is connected to a side chain connected to a backbone of the non-conducting polymer.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method for graphene/lithium titanate coated lithium sulfide composite material

ActiveCN105609735AImprove conductivityImprove ionic conductivityCell electrodesSecondary cellsCharge dischargeBall mill

The invention provides a preparation method for a graphene / lithium titanate coated lithium sulfide composite material. The preparation method comprises the following steps of (1) loading commercial lithium sulfide into a sealed ball milling tank; then putting the tank into a ball mill to be subjected to ball milling to obtain nanometer lithium sulfide; (2) adding tetrabutyl titanate to ethyl alcohol while stirring, and dissolving to form a tetrabutyl titanate ethyl alcohol solution; (3) enabling the nanometer lithium sulfide to be dispersed to an ethyl alcohol solution containing ammonium hydroxide, and adding the tetrabutyl titanate ethyl alcohol solution to a suspension liquid in a dropwise manner; (4) enabling an obtained precursor to be mixed with lithium carbonate powder, and adding the mixture to a muffle furnace under inert gas protection to perform a reaction to obtain the lithium titanate coated lithium sulfide; and (5) adding the lithium titanate coated lithium sulfide and graphene to tetrahydrofuran, and performing an ultrasonic reaction to obtain the graphene / lithium titanate coated lithium sulfide composite material. The lithium titanate structure is relatively stable in the charge-discharge process of the composite material, so that the loss of sulfur-based material can be effectively prevented.

Owner:苏州优越新材料有限公司

A kind of preparation method of lithium sulfide composite material coated with graphene/lithium titanate

ActiveCN105609735BImprove conductivityImprove ionic conductivityCell electrodesSecondary cellsCharge dischargeBall mill

Owner:苏州优越新材料有限公司

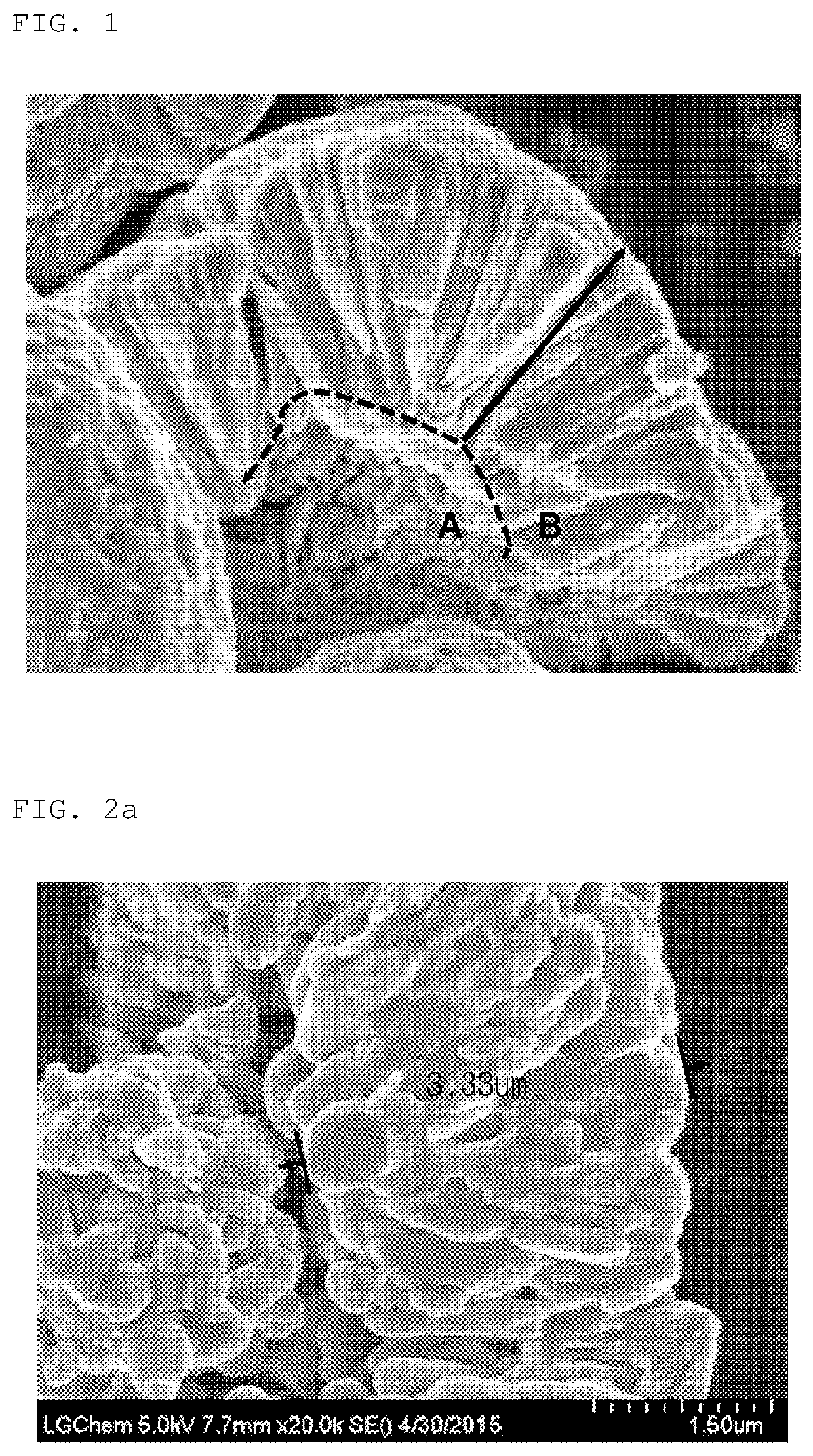

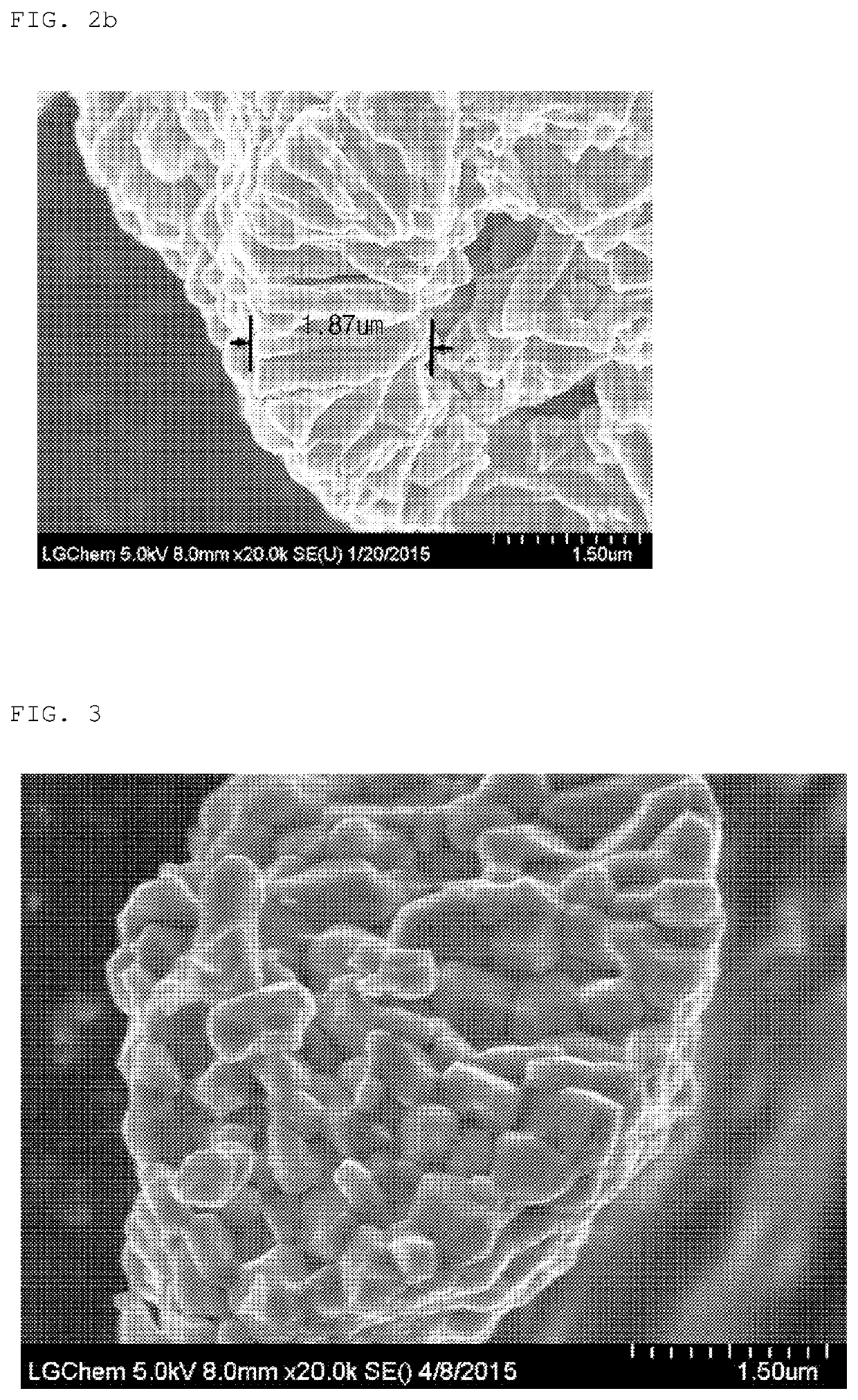

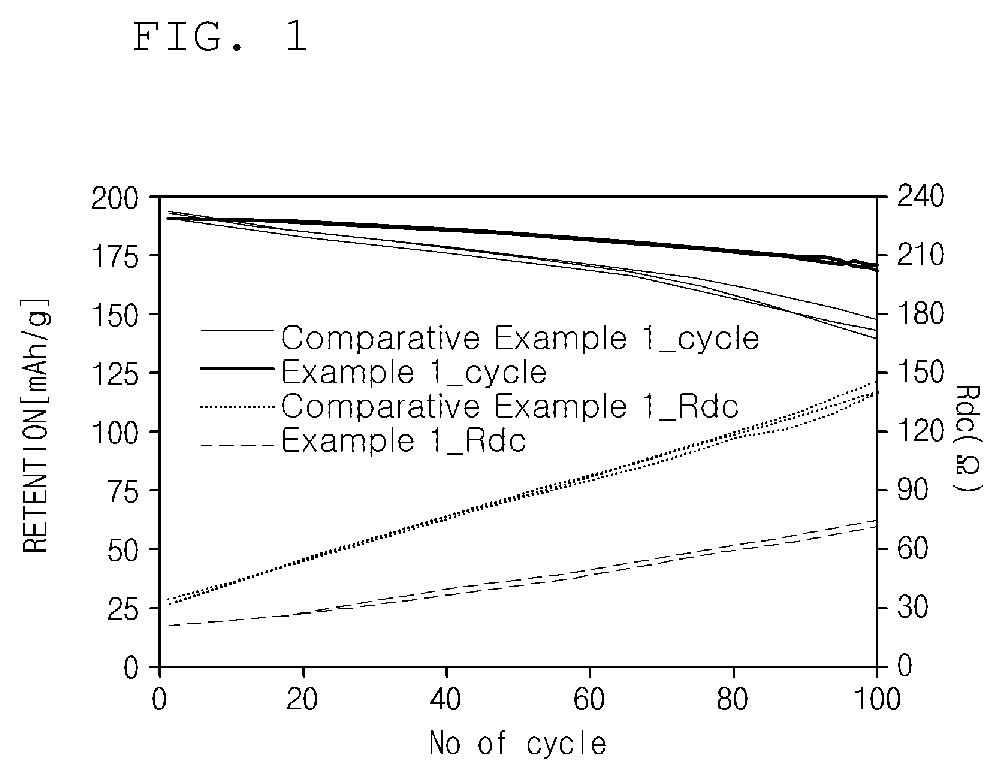

Precursor of positive electrode active material for secondary battery and positive electrode active material prepared using the same

ActiveUS10700352B2Long-term lifeProperty long-term propertySecondary cellsPositive electrodesElectrical batteryMetal hydroxide

The present disclosure relates to a precursor of a positive electrode active material for a secondary battery including a single layer-structured secondary particle in which pillar-shaped primary particles radially oriented in a surface direction from the particle center are aggregated, wherein the secondary particle has a shell shape, and the primary particle includes a composite metal hydroxide of Ni—Co—Mn of the following Chemical Formula 1, and a positive electrode active material prepared using the same:Ni1−(x+y+z)CoxMyMnz(OH)2 [Chemical Formula 1]In Chemical Formula 1, M, x, y and z have the same definitions as in the specification.

Owner:LG CHEM LTD

Additive for electrolyte solution, non-aqueous electrolyte solution including the additive and lithium secondary battery including the electrolyte solution

ActiveUS9666901B2Improve life characteristicsImprove power characteristicsCell electrodesLi-accumulatorsPhysical chemistryNon aqueous electrolytes

An additive for an electrolyte solution includes a lithium salt having an oxalato complex as an anion and a compound represented by following Chemical Formula 1.Wherein, a represents C or Si, b represents H or F, and n represents an integer of 1 to 5. A non-aqueous electrolyte solution including the additive and a lithium secondary battery including the electrolyte solution also are provided.

Owner:LG ENERGY SOLUTION LTD

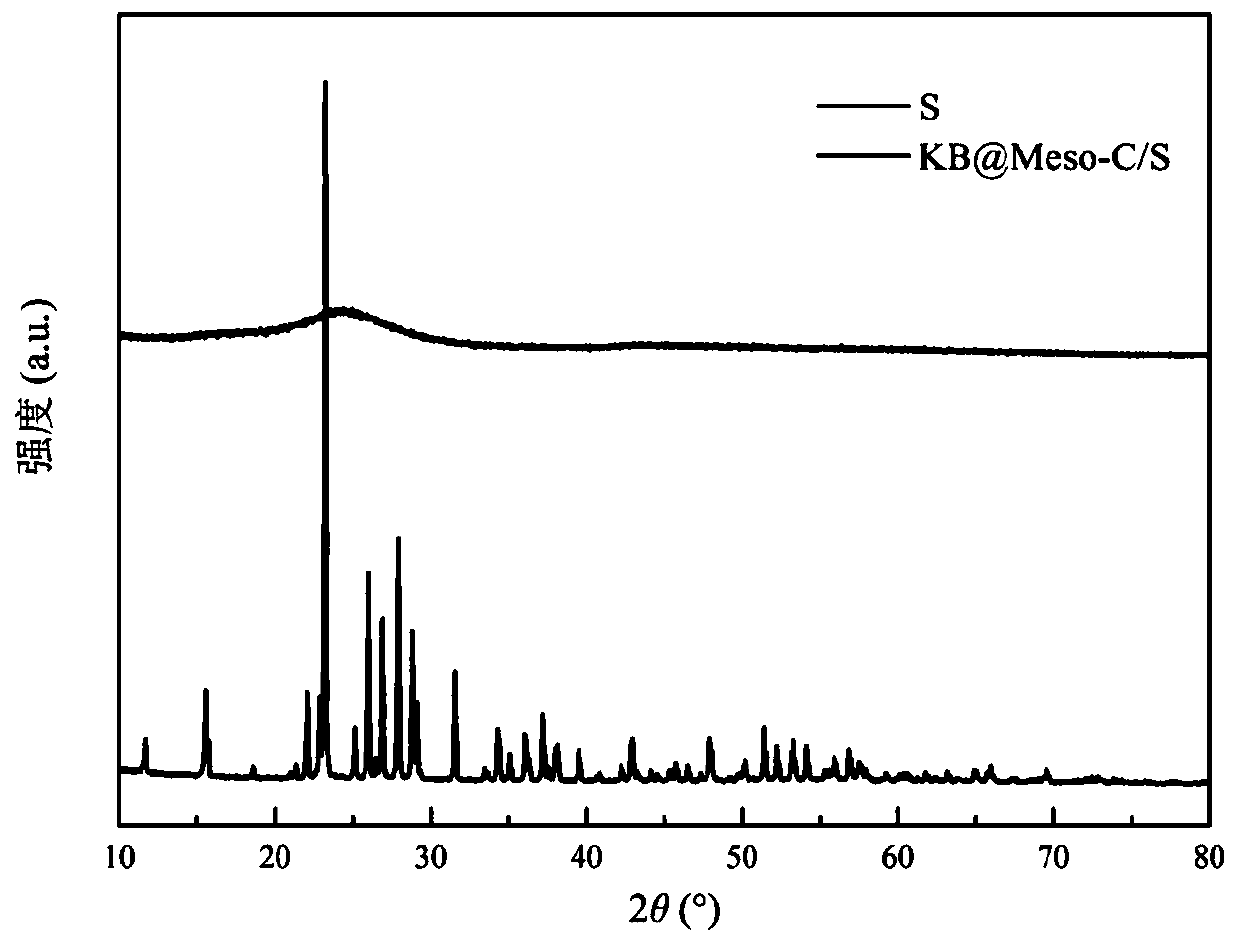

Method for preparing positive electrode material of lithium sulfur battery

InactiveCN109698344AReduce solubilityEase shuttlePositive electrodesLi-accumulatorsN dimethylformamideCarbonization

The invention discloses a method for preparing a positive electrode material of a lithium sulfur battery. The method comprises a step of adding an appropriate amount of zinc nitrate hexahydrate, phthalic acid, ketjen black and a surfactant into N, N-dimethylformamide to prepare a mixed solution and then ultrasonically stirring the mixed solution until the mixed solution is evenly dispersed, a stepof putting the mixed solution into a hydrothermal reaction kettle for hydrothermal reaction to obtain KB@MOF-5, a step of placing KB@MOF-5 into a tube furnace protected by inert gas and obtaining KB@Meso-C after high-temperature carbonization, and a step of thermally fusing active sulfur into a KB@Meso-C composite material through heat treatment in the tube furnace protected by inert gas to obtain KB@Meso-C / S. According to the method, by coating the surface of the positive electrode material with the ketjen black, the dissolution of an intermediate product lithium polysulfide and the shuttlebetween the positive and negative electrodes during the charging and discharging process of the active sulfur in the positive electrode material of the lithium sulfur battery can be effectively relieved, the electronic conductivity and the lithium ion mobility of the positive electrode material of the lithium sulfur battery are improved, and therefore, the reversible specific capacity, the rate performance, the cycle stability and life of the lithium sulfur battery are improved.

Owner:江西中汽瑞华新能源科技有限公司

A kind of high-performance lithium-ion battery and its manufacturing process

InactiveCN102347475BImprove electronic conductivityImprove charge and discharge performanceCell electrodesSecondary cellsConductive polymerCopper foil

The invention relates to a high-performance lithium ion battery. According to the battery, an electrode material is subjected to a nano-composite treatment of grapheme and polyaniline; an anode current collector comprises aluminium foil; a cathode current collector comprises copper foil; a conductive agent comprises superconducting carbon black, conductive graphite or acetylene black; a binding agent comprises styrene butadiene rubber, carboxymethylcellulose sodium, polytetrafluoroethylene, polyvinylidene difluoride or hydroxy propyl methylcellulose; a electrolyte comprises liquid electrolyte or a polymer electrolyte containing a conductive polymer, a nano-material, or a mixture comprising the conductive polymer and the nano-material; a membrane is subjected to a high temperature resistant insulation coating treatment, or directly adopts a high temperature resistant insulating porous polymer matrix. A preparation process for the high-performance lithium ion battery comprises: material preparing, coating, drying, rolling, slicing, coil winding or sheet stacking, assembling, liquid injecting, formation and capacity distributing. The lithium ion battery provided by the present invention has characteristics of excellent charge and discharge performance at the large rate, small capacity fading, good heat stability, good safety performance and long electrode cycle life, and can be widely applicable for the fields of electric bicycles, electric motorcycles, electric cars and the like.

Owner:LUNAN RES INST OF COAL CHEM

A surface-coated lithium nickel manganese oxide material, lithium battery and preparation method thereof

InactiveCN106099084BSmall and uniform particle sizeImprove electrochemical performanceCell electrodesSecondary cellsDivalent metal ionsManganese oxide

The invention discloses a surface-coating type lithium nickel manganese oxide material, a lithium battery and a preparation method thereof. The surface-coating type lithium nickel manganese oxide material is characterized in that the surface of LiNi0.5Mn1.5O4 is coated with LiM0.5Mn1.5O4 with spinel structure, wherein M is positive bivalent metal ion. The surface-coating type lithium nickel manganese oxide material is characterized in that the particle size is small and uniform, and the electro-chemical property of LiNi0.5Mn1.5O4 is favorably improved; the surface of the prepared material is coated with LiM0.5Mn1.5O4 with electro-chemical inactivity, so that the good lithium ion transfer rate and good structure stability of LiNi0.5Mn1.5O4 are guaranteed in the charging and discharging process, and the side reaction of LiNi0.5Mn1.5O4 and electrolyte is inhibited. The preparation method has the advantages that the operation is simple, the preparation is convenient, and the cost is low; the significance on promoting the application and development of LiNi0.5Mn1.5O4 positive electrode material is realized.

Owner:SICHUAN JIANXING LITHIUM BATTERY

Positive Electrode Active Material for Lithium Secondary Battery, Method of Preparing the Same, and Positive Electrode for Lithium Secondary Battery and Lithium Secondary Battery which Include the Positive Electrode Active Material

ActiveUS20200328417A1Reduce resistanceImprove structural stabilityPositive electrodesLi-accumulatorsManganeseYttrium

A positive electrode active material includes a lithium transition metal oxide represented by Formula 1, and a lithium-containing inorganic compound layer formed on a surface of the lithium transition metal oxide,Li1+a(NibCocXdM1eM2f)1−aO2 [Formula 1]in Formula 1, X is at least one selected from the group consisting of manganese (Mn) and aluminum (Al), M1 is at least one selected from the group consisting of sulfur (S), fluorine (F), phosphorus (P), and nitrogen (N), M2 is at least one selected from the group consisting of zirconium (Zr), boron (B), cobalt (Co), tungsten (W), magnesium (Mg), cerium (Ce), tantalum (Ta), titanium (Ti), strontium (Sr), barium (Ba), hafnium (Hf), F, P, S, lanthanum (La), and yttrium (Y), 0≤a≤0.1, 0.6≤b≤0.99, 0≤c≤0.2, 0≤d≤0.2, 0<e≤0.1, and 0<f≤0.1. A method of preparing the positive electrode active material, a positive electrode and a lithium secondary battery are also provided.

Owner:LG CHEM LTD

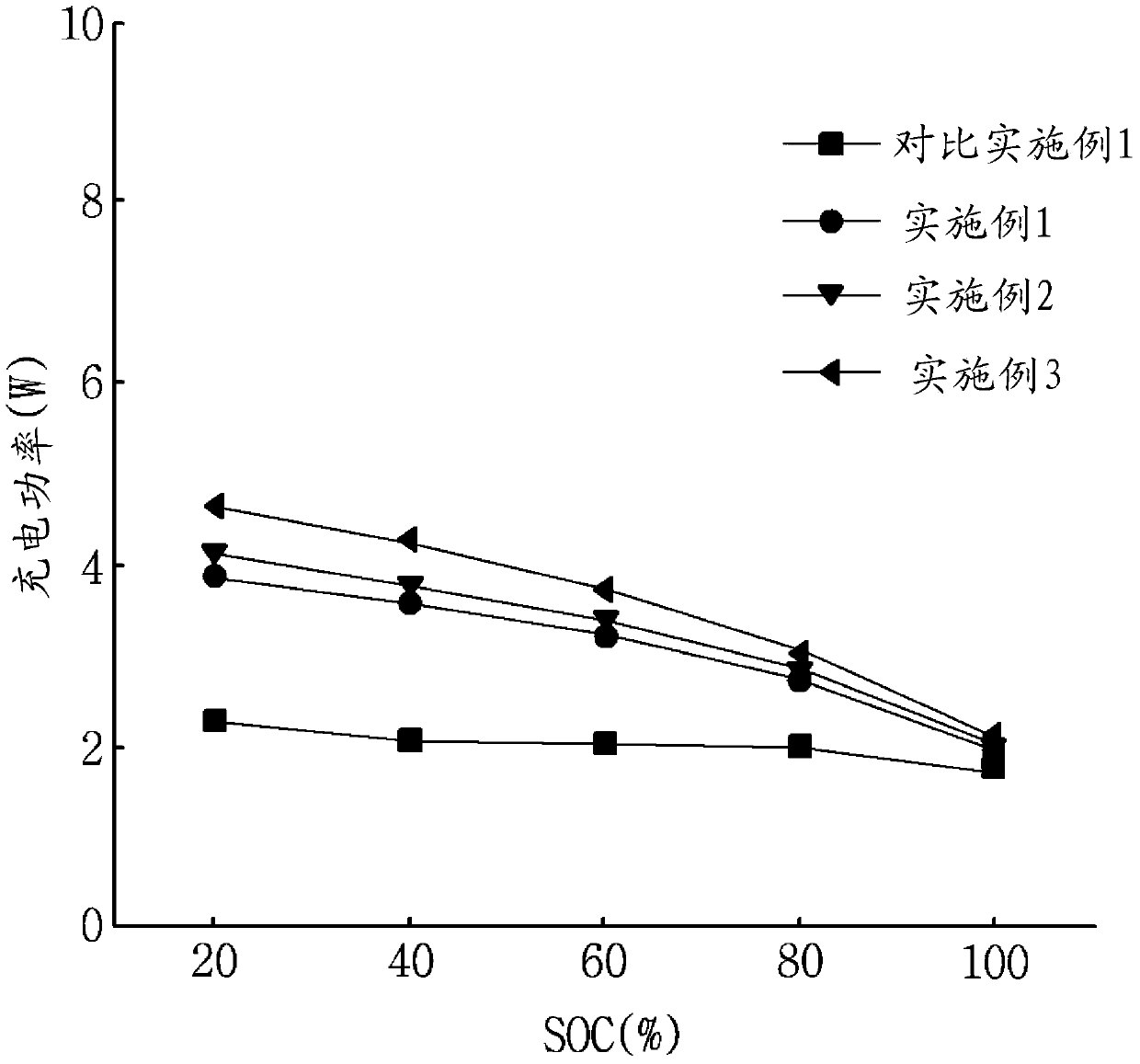

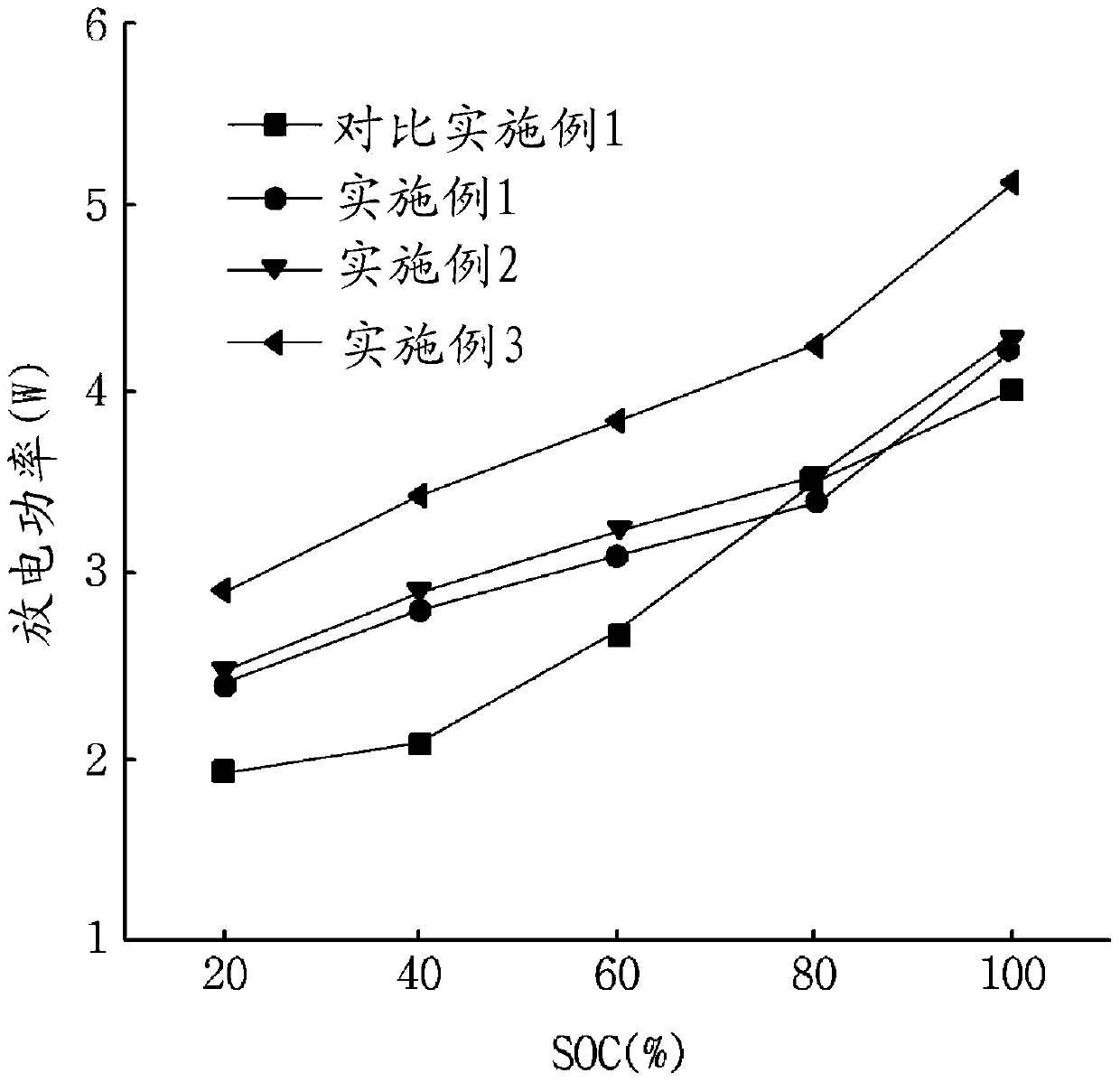

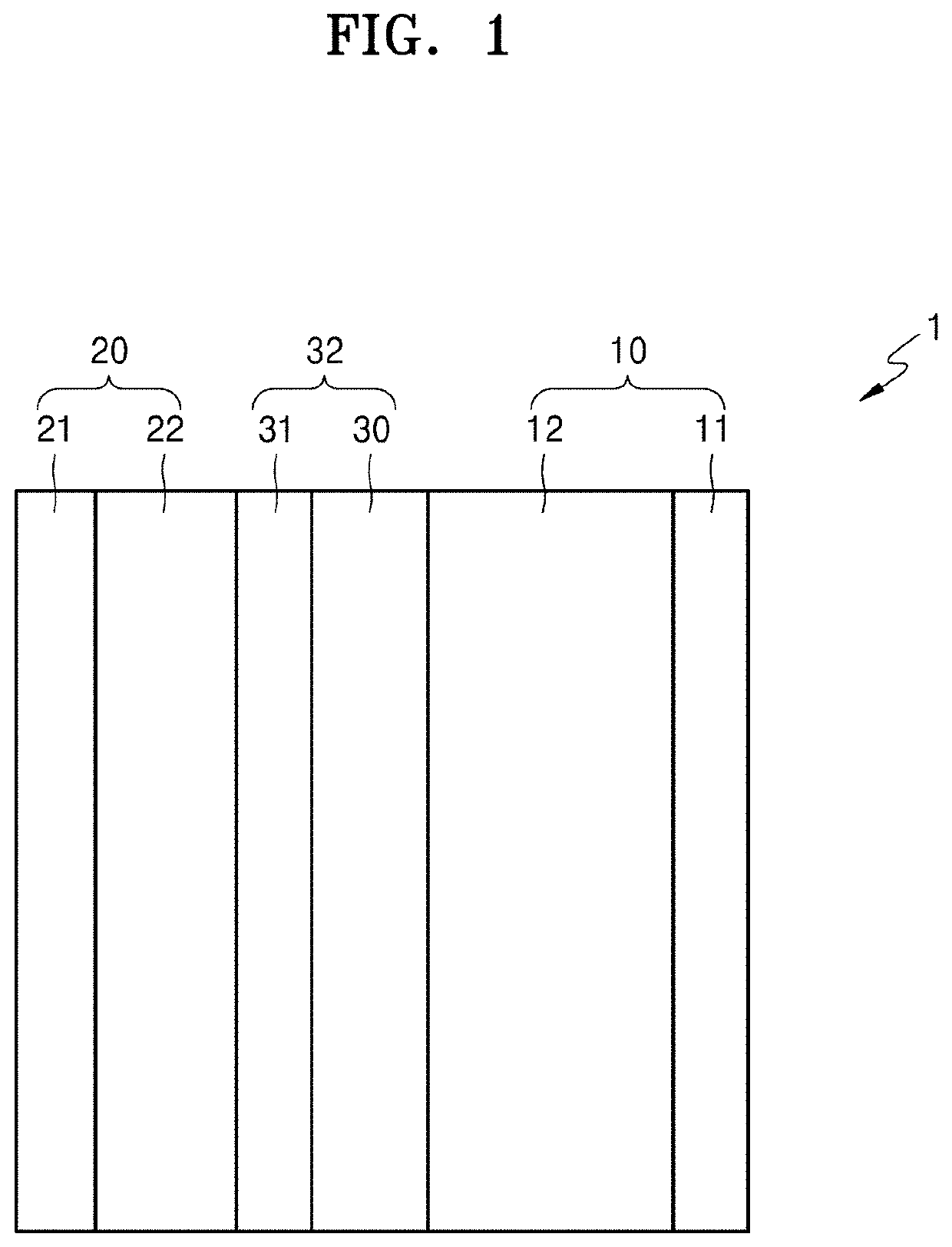

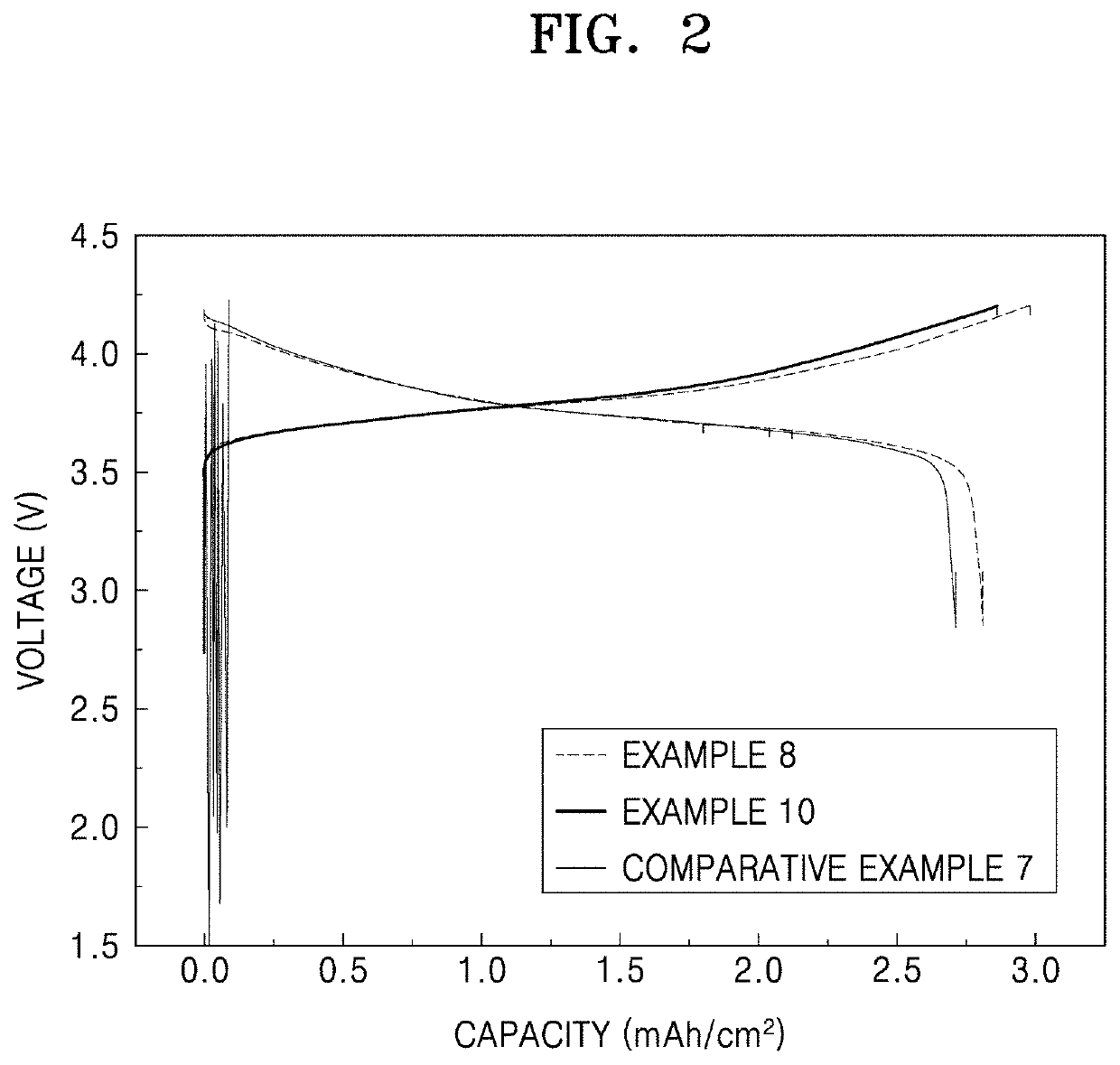

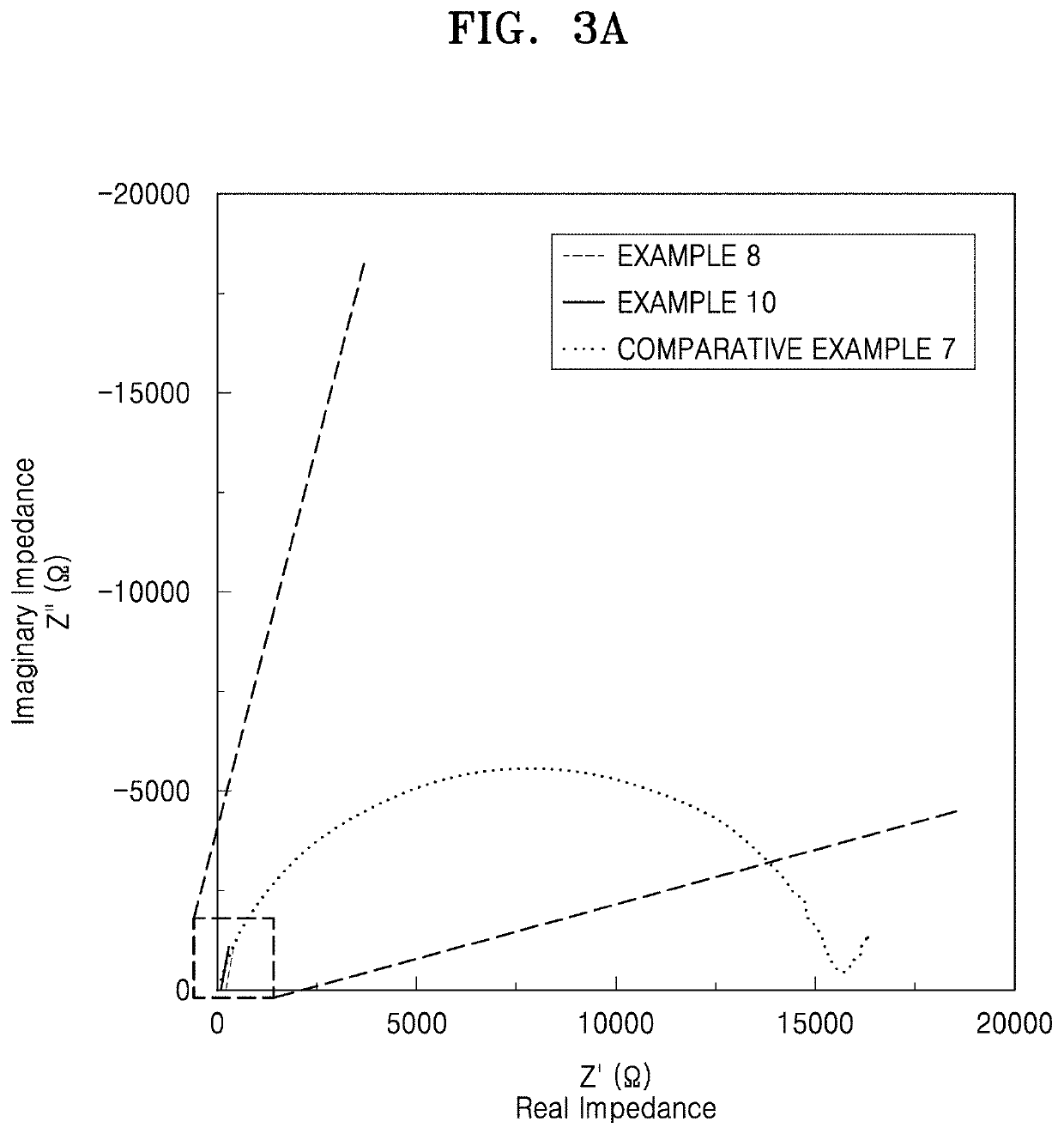

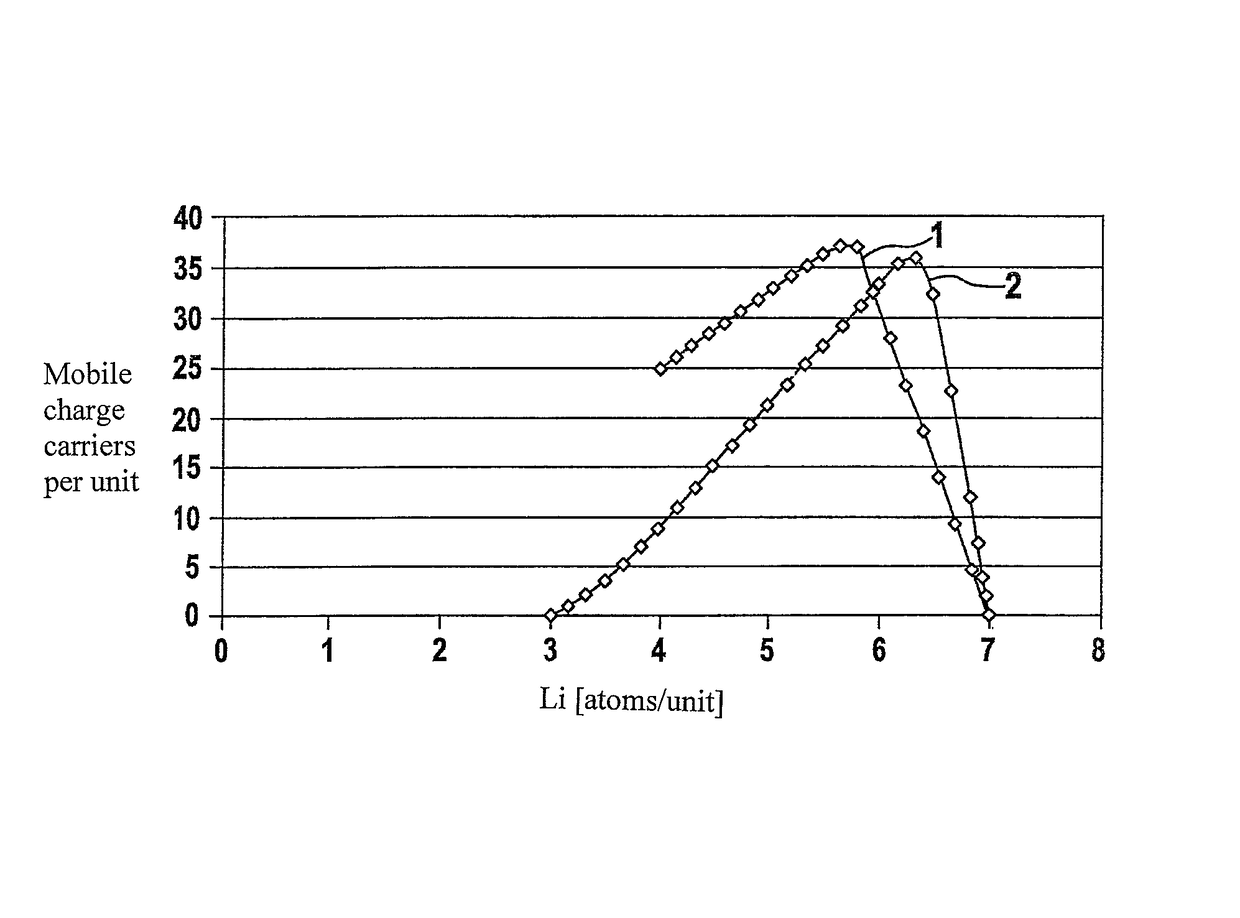

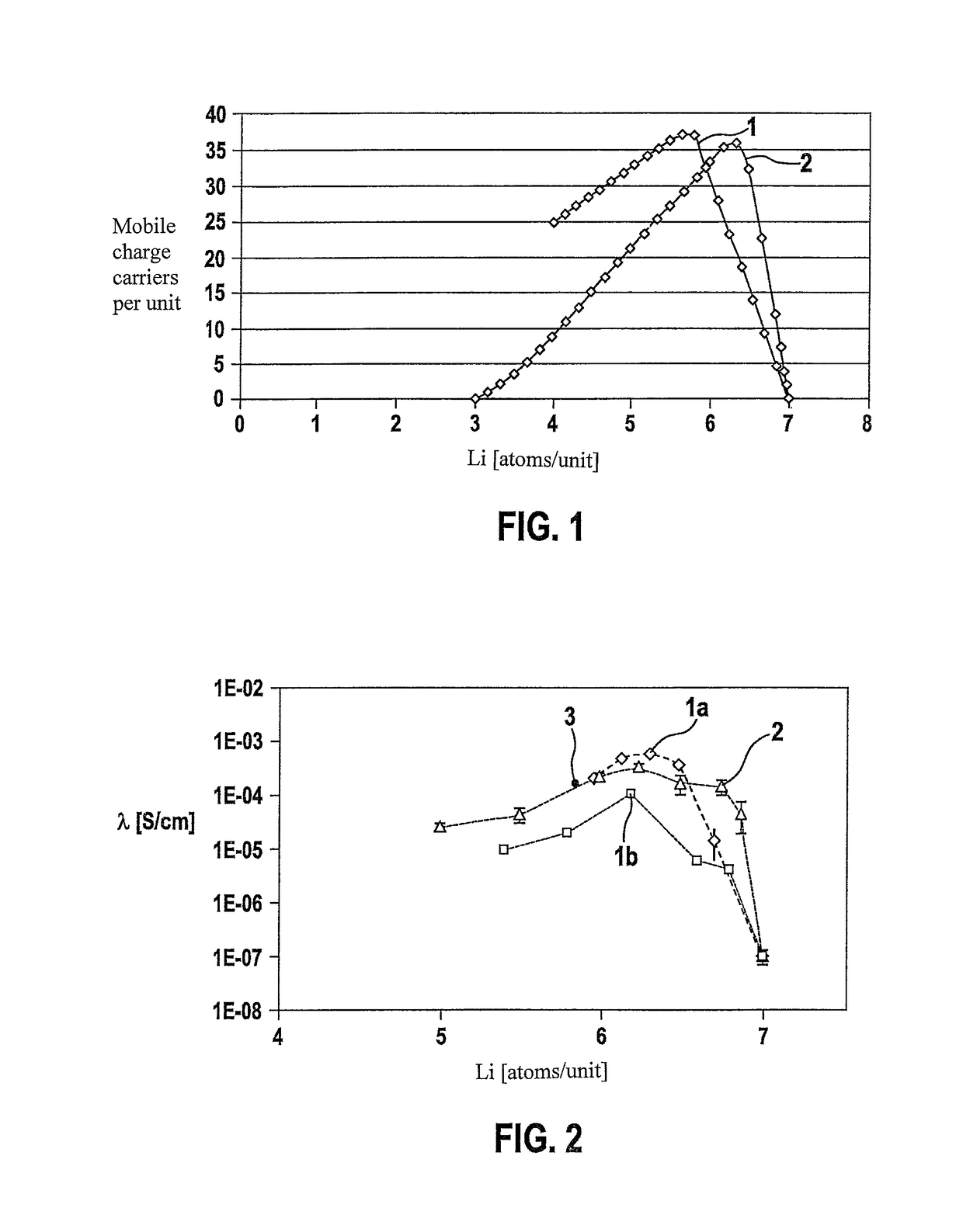

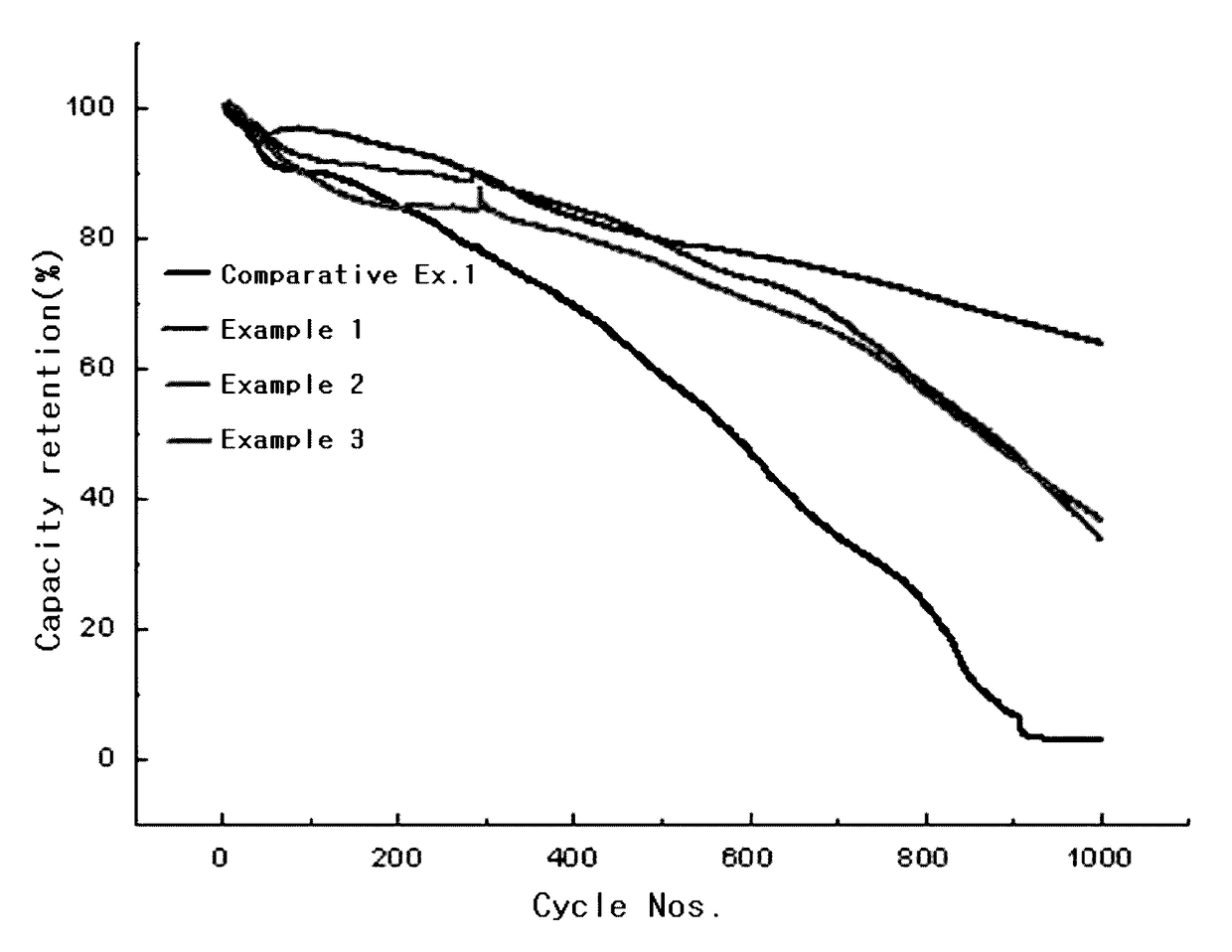

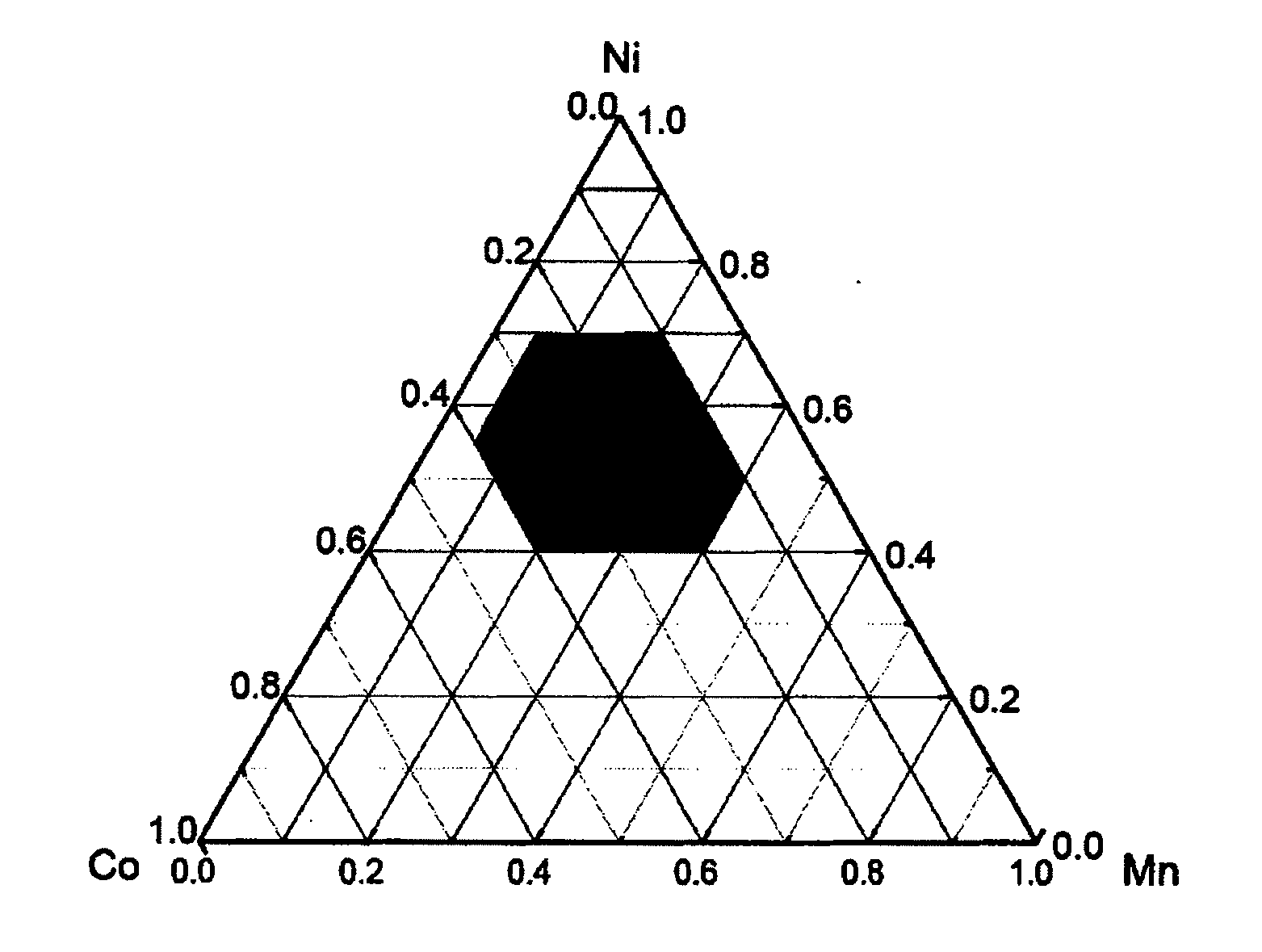

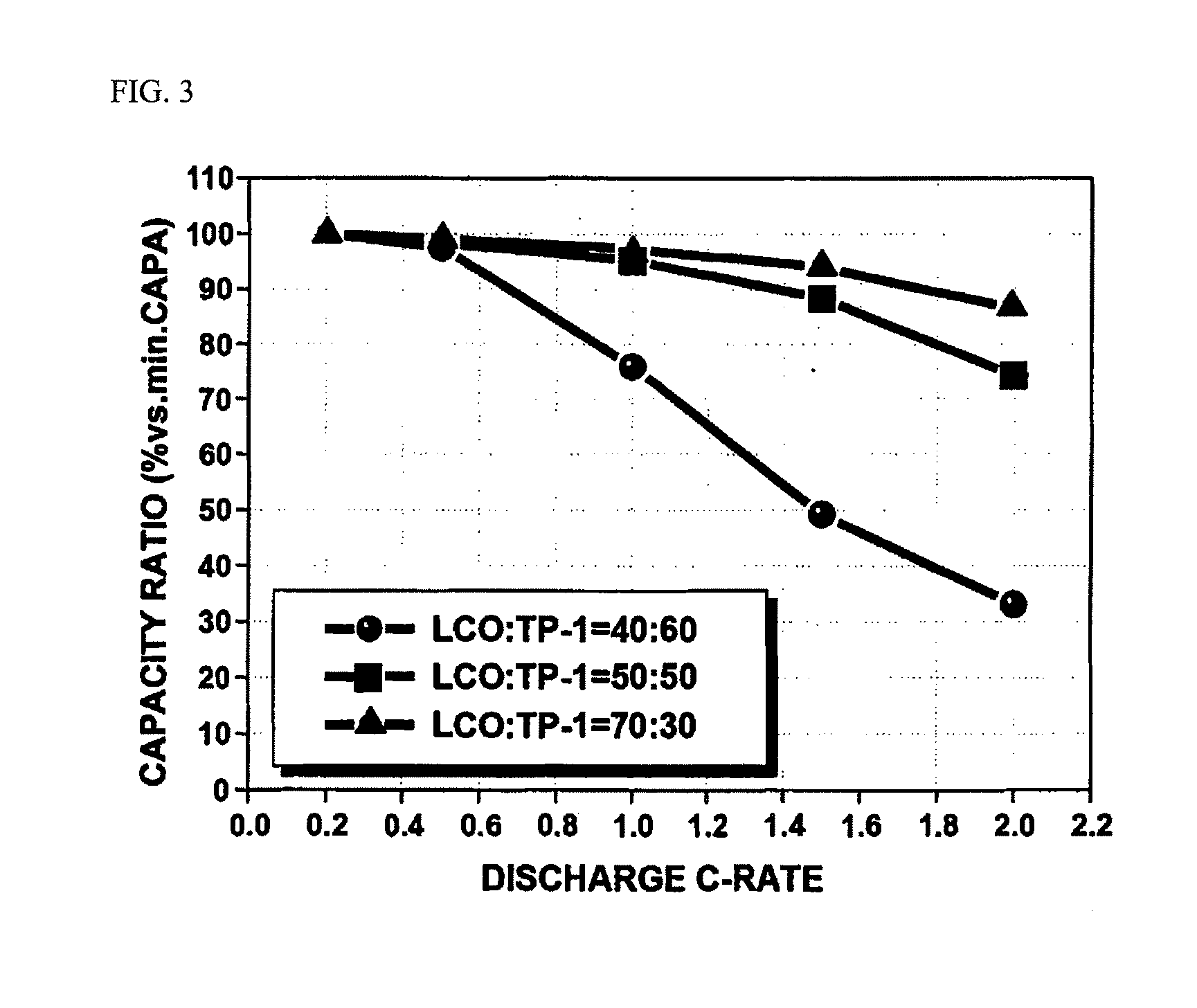

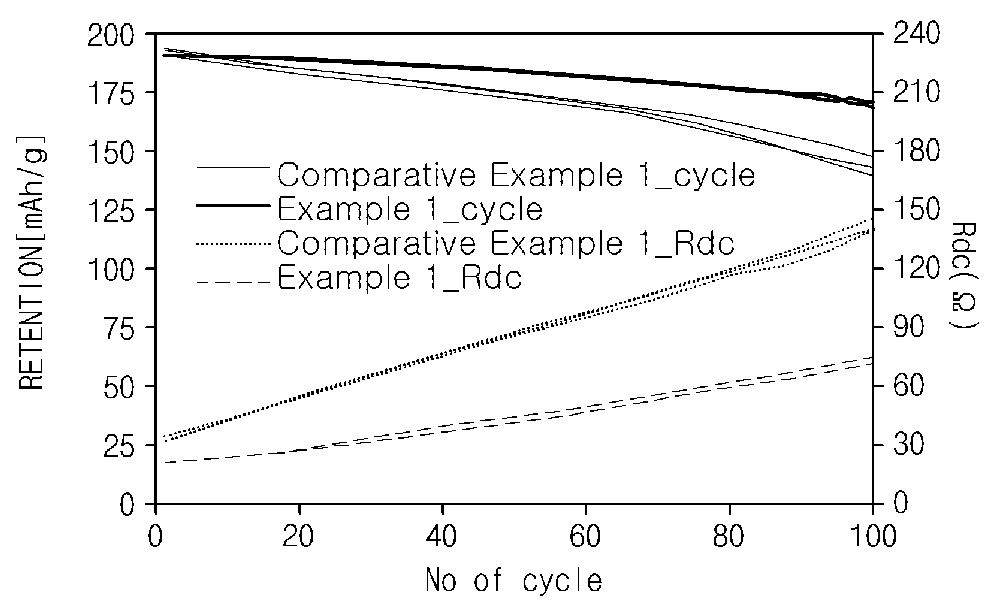

Cathode materials having high energy density and lithium secondary battery containing the same

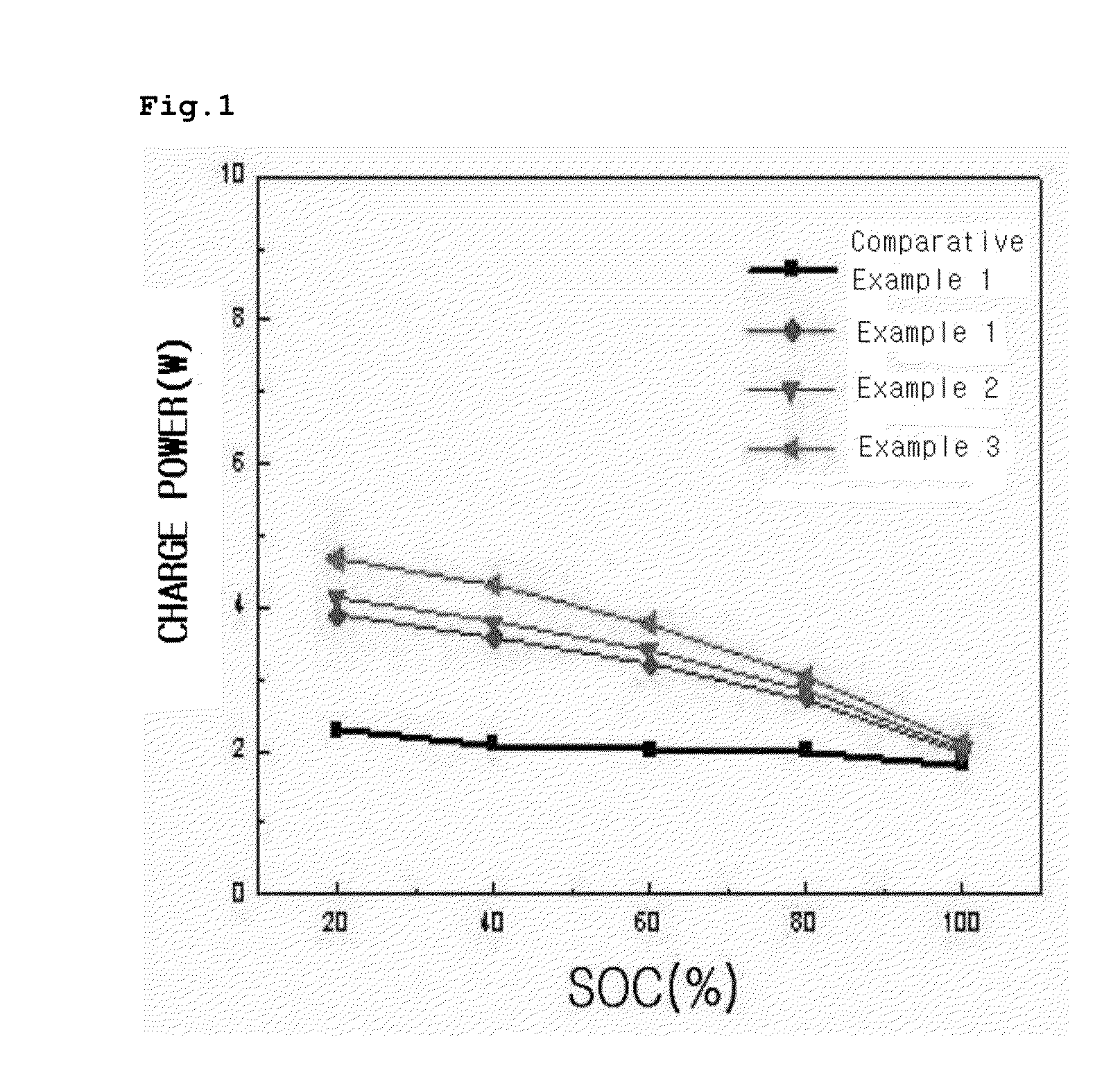

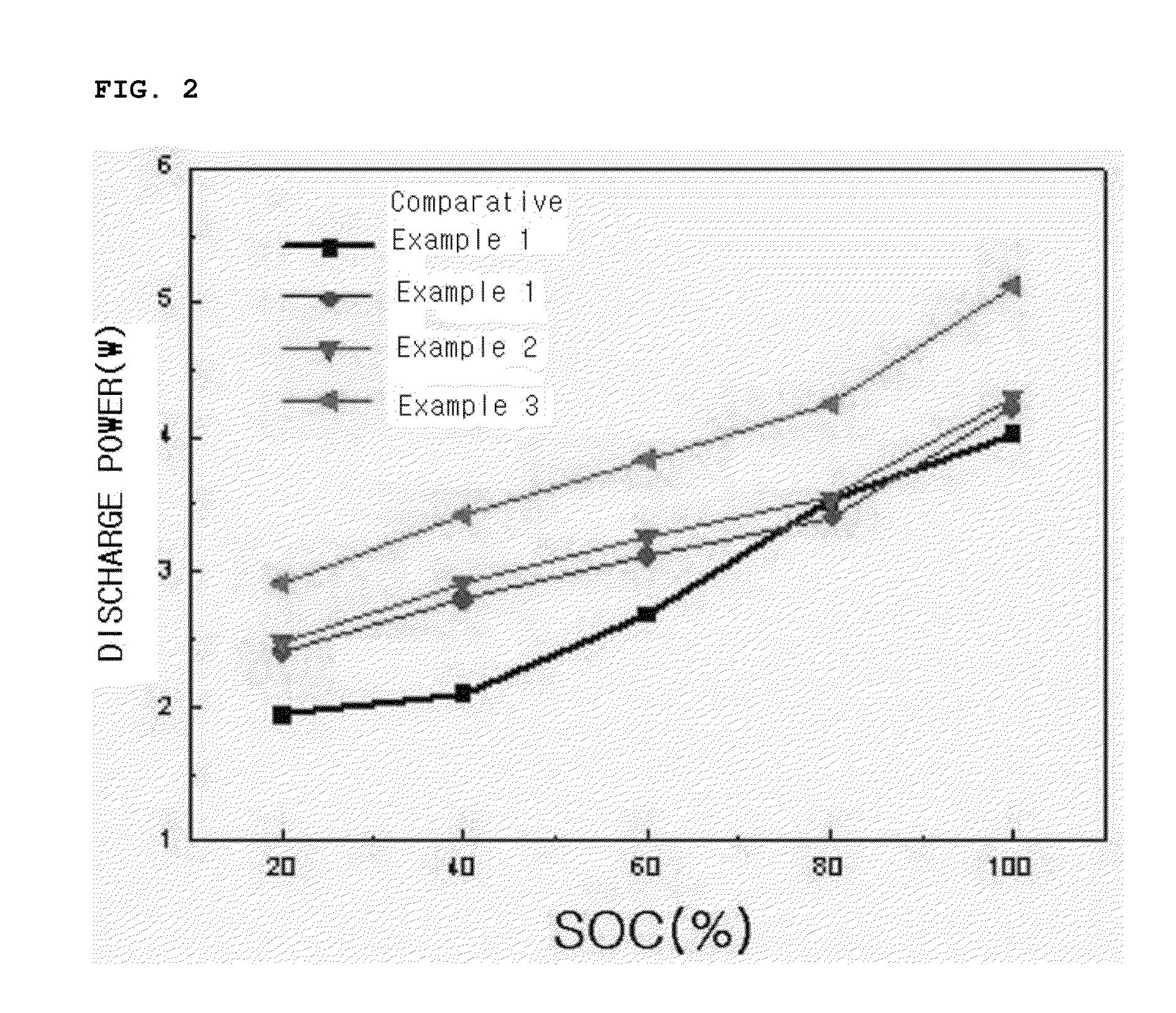

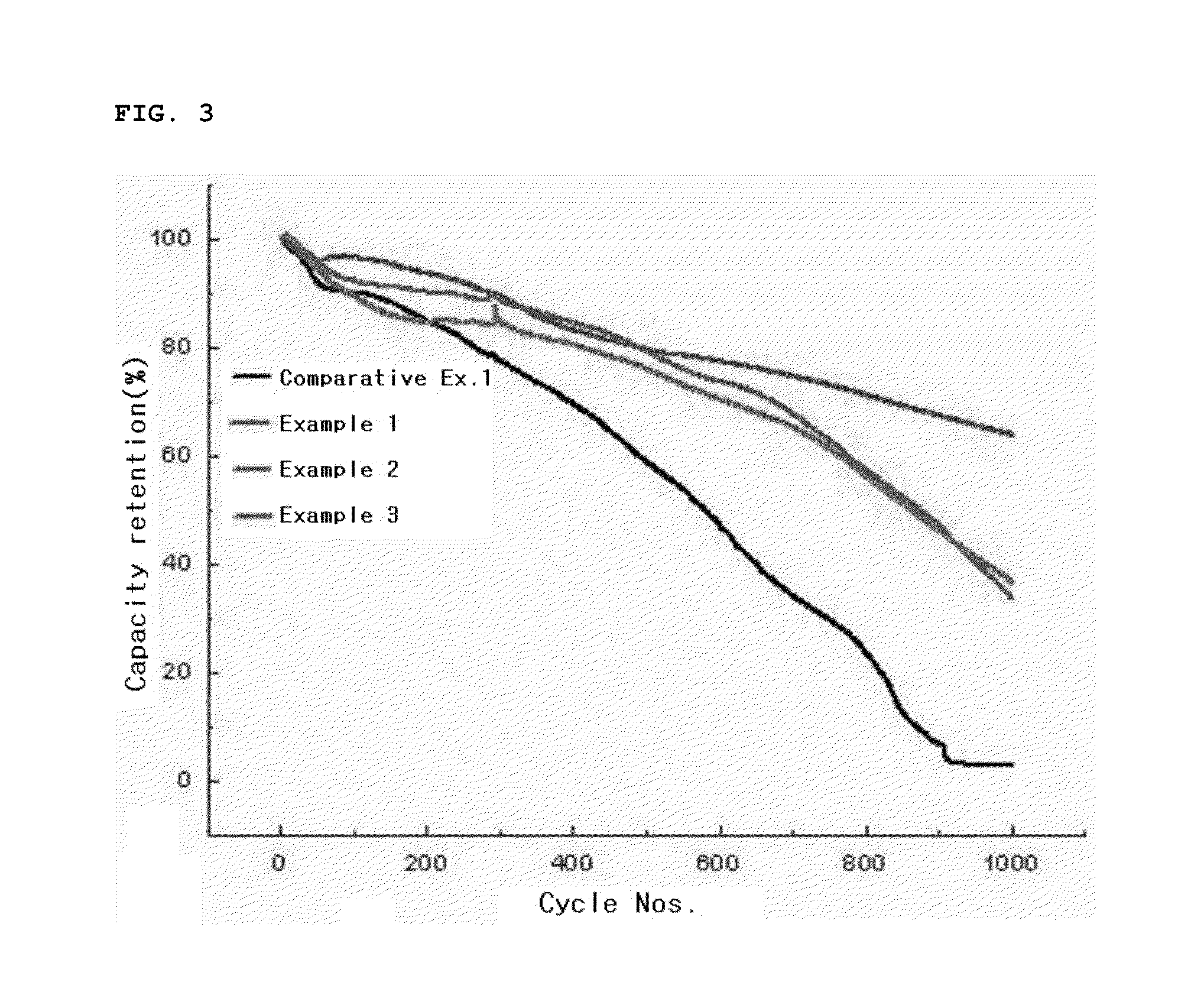

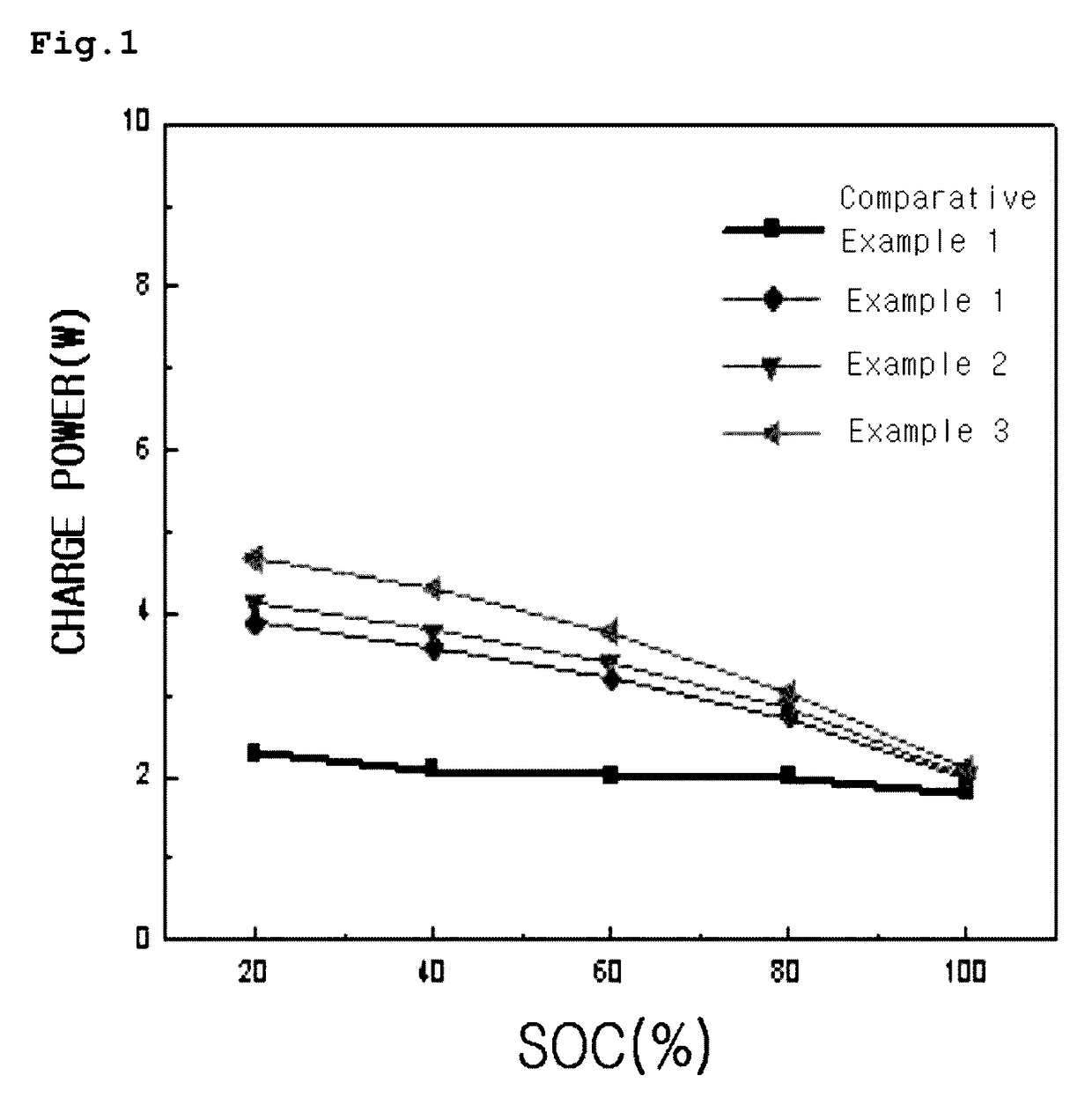

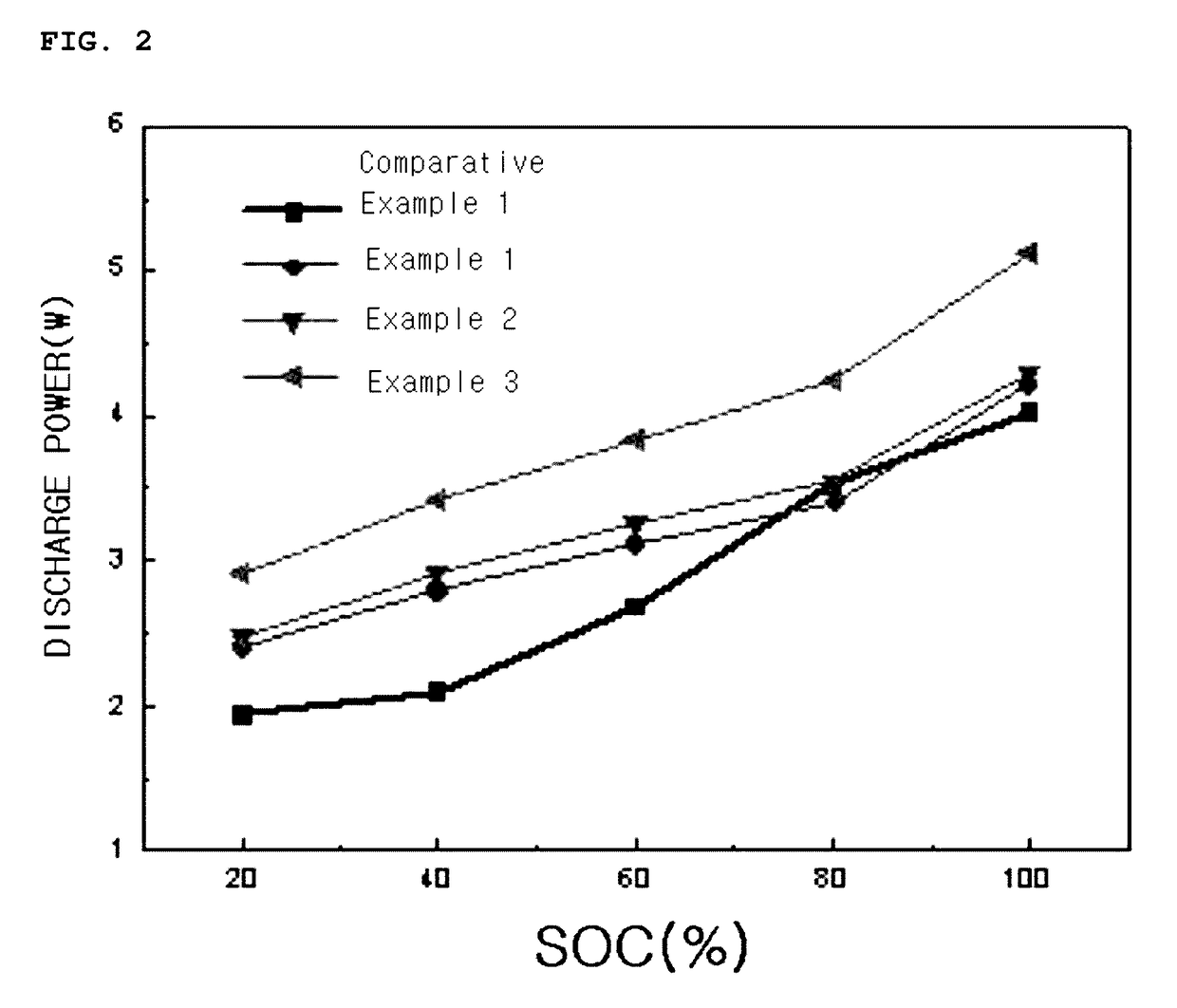

ActiveUS20120225343A1Reduce amountImprove lithium ion mobilityConductive materialPositive electrodesHigh energyMixing ratio

Disclosed is a cathode material comprising a mixture of an oxide powder (a) defined herein and an oxide powder (b) selected from the group consisting of an oxide powder (b1) defined herein and an oxide powder (b2) defined herein and a combination thereof wherein a mix ratio of the two oxide powders (oxide powder (a): oxide powder (b)) is 50:50 to 90:10. The cathode material uses a combination of an oxide powder (a) and 50% or less of an oxide powder (b) which can exert high capacity, high cycle stability, superior storage stability and high-temperature stability, thus advantageously exhibiting high energy density and realizing high capacity batteries.

Owner:LG ENERGY SOLUTION LTD

Positive electrode active material for lithium secondary battery, method of preparing the same, and positive electrode for lithium secondary battery and lithium secondary battery which include the positive electrode active material

ActiveUS11489156B2Improve structural stabilityImprove life characteristicsPositive electrodesLi-accumulatorsPhysical chemistryManganese

A positive electrode active material includes a lithium transition metal oxide represented by Formula 1, and a lithium-containing inorganic compound layer formed on a surface of the lithium transition metal oxide,Li1+a(NibCocXdM1eM2f)1−aO2 [Formula 1]in Formula 1, X is at least one selected from the group consisting of manganese (Mn) and aluminum (Al), M1 is at least one selected from the group consisting of sulfur (S), fluorine (F), phosphorus (P), and nitrogen (N), M2 is at least one selected from the group consisting of zirconium (Zr), boron (B), cobalt (Co), tungsten (W), magnesium (Mg), cerium (Ce), tantalum (Ta), titanium (Ti), strontium (Sr), barium (Ba), hafnium (Hf), F, P, S, lanthanum (La), and yttrium (Y), 0≤a≤0.1, 0.6≤b≤0.99, 0≤c≤0.2, 0≤d≤0.2, 0<e≤0.1, and 0<f≤0.1. A method of preparing the positive electrode active material, a positive electrode and a lithium secondary battery are also provided.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com