Preparation method for graphene/lithium titanate coated lithium sulfide composite material

A lithium titanate coating, composite material technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve problems such as potential safety hazards, failure of lithium-sulfur secondary batteries, and restrictions on the application of lithium-sulfur batteries. Effects of structural stability, improved electronic conductivity, and improved lithium ion mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

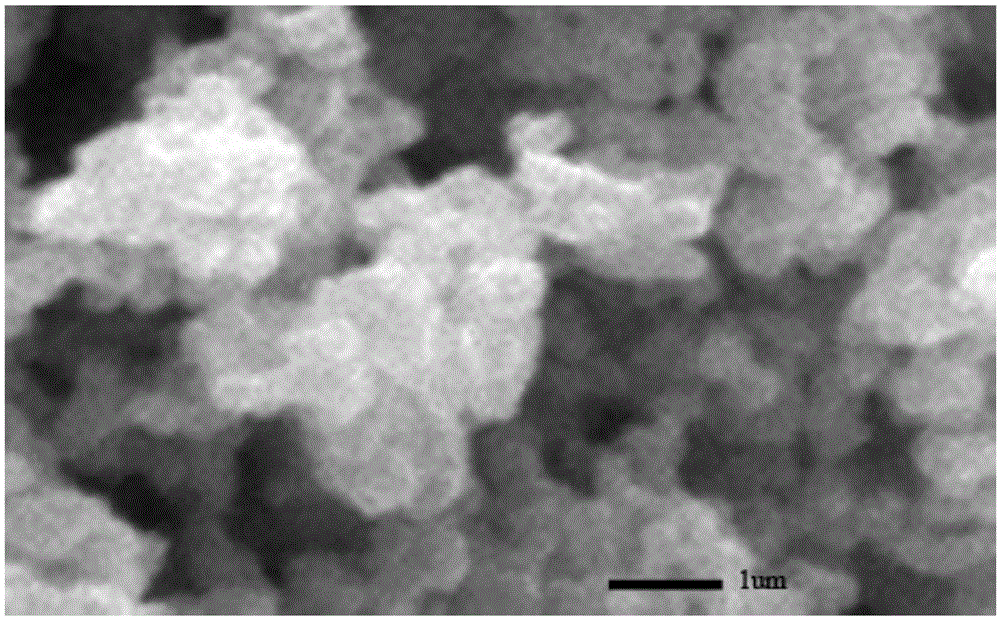

Image

Examples

Embodiment 1

[0020] (1) Put commercial lithium sulfide into a sealed ball mill tank in an inert gas-protected glove box, and then put it into a ball mill for ball milling for 0.5 hours at a ball milling speed of 3000 rpm to obtain nanometer lithium sulfide.

[0021] (2) Add tetrabutyl titanate into ethanol under stirring, and dissolve to form a tetrabutyl titanate ethanol solution with a mass concentration of 10%.

[0022] (3) Disperse the obtained nano-lithium sulfide into the ethanol solution containing ammonia water, stir continuously to form a 10% 50ml suspension, in which the volume concentration of ammonia water is 5%, and then add 50ml tetrabutyl titanate ethanol solution dropwise into the suspension, stirred and reacted at 40°C for 48 hours, and then evaporated the solvent to obtain a solid powder, which was added to a muffle furnace protected by an inert gas for reaction, and reacted at 300°C for 3 hours to obtain a precursor.

[0023] (4) Mix the obtained precursor with lithium c...

Embodiment 2

[0026] (1) Put commercial lithium sulfide into a sealed ball mill tank in an inert gas-protected glove box, and then put it into a ball mill for 3 hours of ball milling at a milling speed of 500 rpm to obtain nanometer lithium sulfide.

[0027] (2) Add tetrabutyl titanate into ethanol under stirring, and dissolve to form a tetrabutyl titanate ethanol solution with a mass concentration of 5%.

[0028] (3) Disperse the obtained nano-lithium sulfide into the ethanol solution containing ammonia water, stir continuously to form a 5% 50ml suspension, wherein the volume concentration of ammonia water is 1%, and then add 5ml tetrabutyl titanate ethanol solution dropwise to In the suspension, stirred and reacted at 60°C for 24 hours, and then evaporated the solvent to obtain a solid powder, which was added to a muffle furnace protected by an inert gas for reaction, and reacted at 400°C for 1 hour to obtain a precursor.

[0029] (4) The obtained precursor was mixed with lithium carbonat...

Embodiment 3

[0032] (1) Put commercial lithium sulfide into a sealed ball mill tank in an inert gas-protected glove box, and then put it into a ball mill for ball milling for 1 hour at a ball milling speed of 2000 rpm to obtain nanometer lithium sulfide.

[0033] (2) Add tetrabutyl titanate into ethanol under stirring, and dissolve to form a tetrabutyl titanate ethanol solution with a mass concentration of 7%.

[0034] (3) Disperse the obtained nano-lithium sulfide into an ethanol solution containing ammonia water, stir continuously to form a 6% 50ml suspension, in which the volume concentration of ammonia water is 2%, and then add 10ml tetrabutyl titanate ethanol solution dropwise to In the suspension, stirred and reacted at 50°C for 36 hours, and then evaporated the solvent to obtain a solid powder, which was added to a muffle furnace protected by an inert gas for reaction, and reacted at 350°C for 2 hours to obtain a precursor.

[0035] (4) Mix the obtained precursor with lithium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com