Mixed lithium-rich positive electrode material and preparation method and application thereof

A lithium-rich positive electrode material and a technology for a positive electrode material are applied in the field of hybrid lithium-rich positive electrode material and its preparation, which can solve the problems of unfavorable high specific energy positive electrode material, low specific capacity of positive electrode material, complicated preparation process, etc. The effect of migration ability, good material performance consistency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

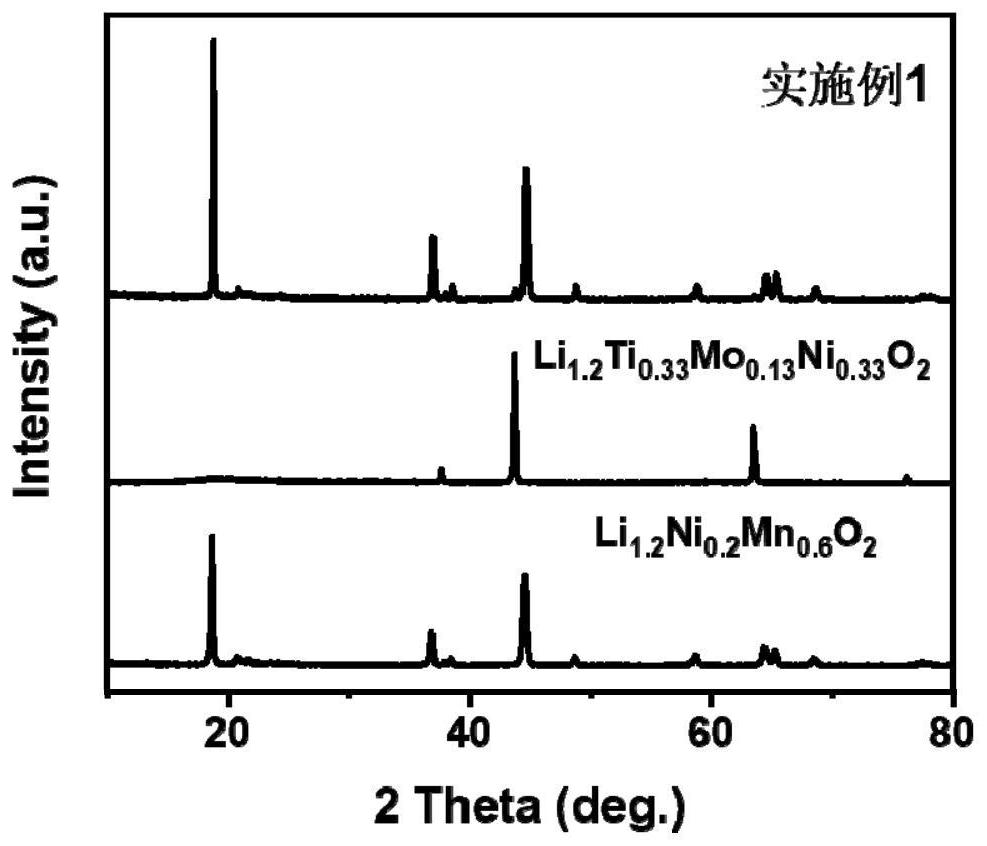

Embodiment 1

[0054] A mixed Li 1.2 Ni 0.2 mn 0.6 o 2 / Li 1.2 Ti 0.33 Mo 0.13 Ni 0.33 o 2 The lithium-rich positive electrode material, its preparation method comprises the following steps:

[0055] S1. Weigh and mix manganese sulfate and nickel sulfate with a molar ratio of 3:1 according to the composition of the lithium-rich cathode material, add distilled water to make a 2mol / L metal salt solution (the total molar number of transition metals is 2mol), and then weigh 2mol sodium carbonate Prepare a 2mol / L solution, use ammonia water as a complexing agent, slowly add the three solutions into the reaction kettle, react at 55°C for 12 hours at pH = 8, filter to obtain a precipitate, and vacuum dry to obtain a carbonate precursor;

[0056] S2, mix and stir the carbonate precursor and lithium carbonate (the molar ratio of precursor and lithium source: 1:1.05) with absolute ethanol as solvent until the solvent evaporates completely, then transfer the mixture to the crucible, In the Fur...

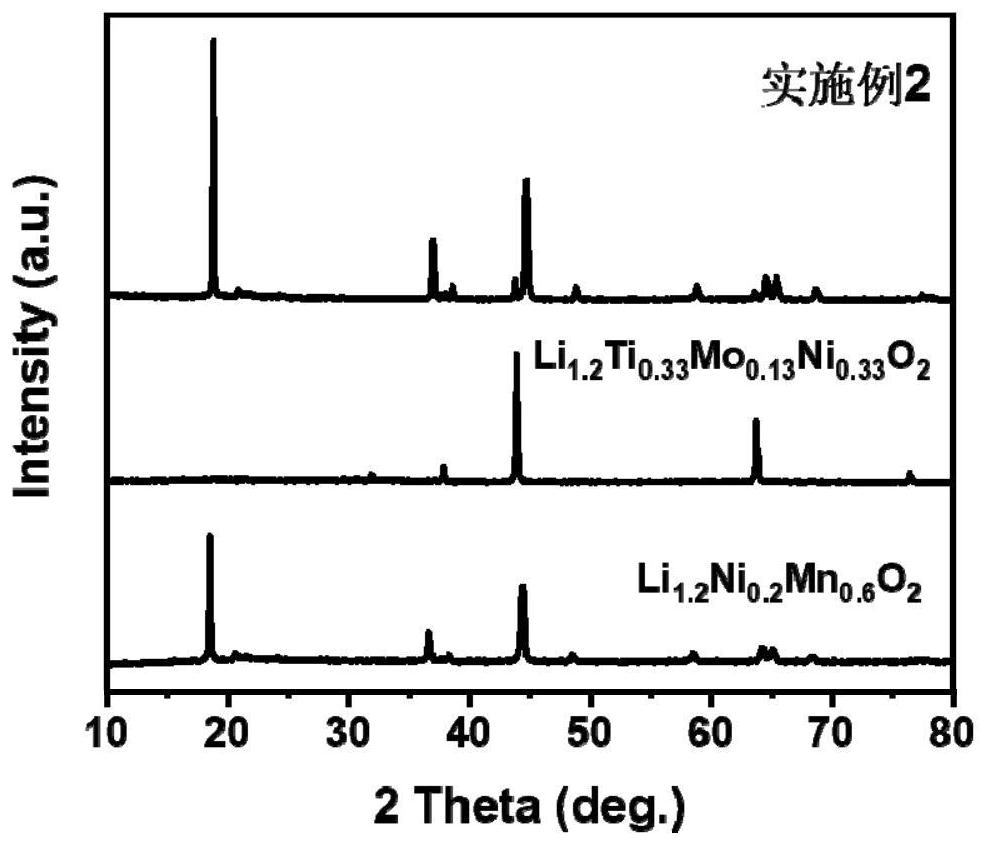

Embodiment 2

[0064] A mixed Li 1.2 Ni 0.2 mn 0.6 o 2 / Li 1.2 Ti 0.33 Mo 0.13 Ni 0.33 o 2 The lithium-rich positive electrode material, its preparation method comprises the following steps:

[0065] S1. Weigh and mix manganese sulfate and nickel sulfate with a molar ratio of 3:1 according to the composition of the lithium-rich cathode material, add distilled water to make a 2mol / L metal salt solution (the total molar number of transition metals is 2mol), and then weigh 2mol sodium carbonate Prepare a 2mol / L solution, use ammonia water as a complexing agent, slowly add the three solutions into the reaction kettle, react at 55°C for 12 hours at pH = 8, filter to obtain a precipitate, and vacuum dry to obtain a carbonate precursor;

[0066] S2, mix and stir the carbonate precursor and lithium carbonate (the molar ratio of precursor and lithium source: 1:1.05) with absolute ethanol as solvent until the solvent evaporates completely, then transfer the mixture to the crucible, In the Fur...

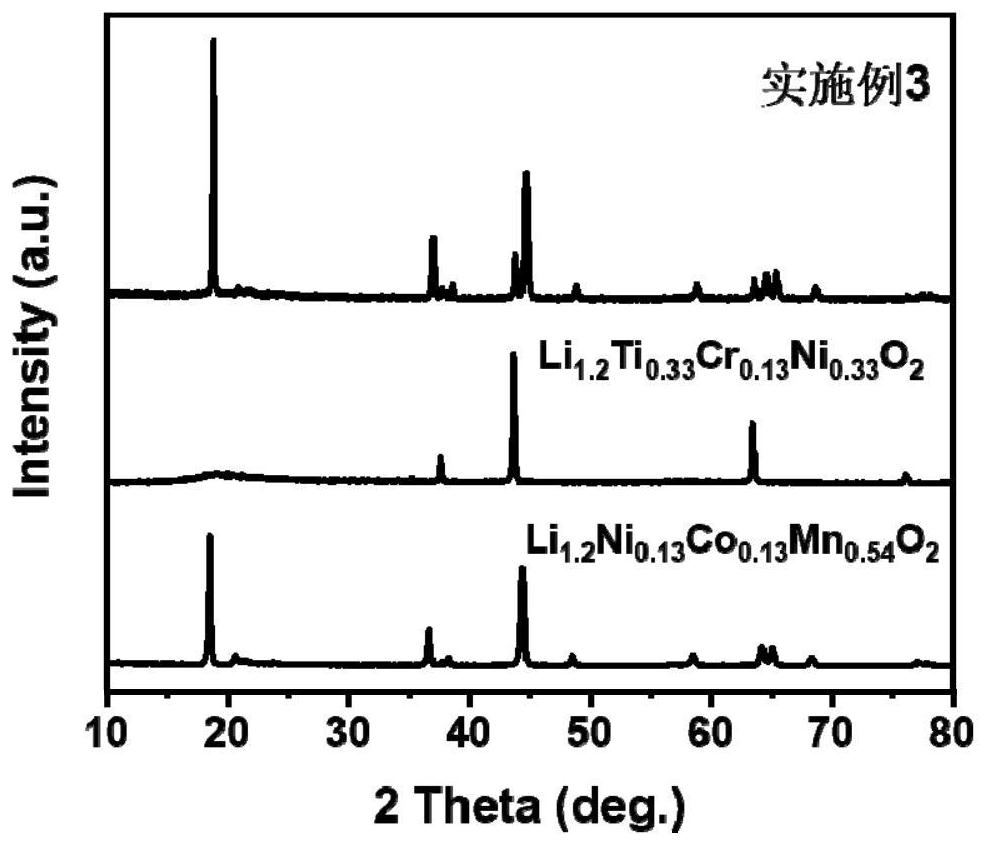

Embodiment 3

[0074] A mixed Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 / Li 1.2 Ti 0.33 Cr 0.13 Ni 0.33 o 2 The lithium-rich positive electrode material, its preparation method comprises the following steps:

[0075] S1. Weigh and mix manganese sulfate, cobalt sulfate and nickel sulfate with a molar ratio of 4:1:1 according to the composition of the lithium-rich positive electrode material, add distilled water to form a 2mol / L metal salt solution (the total molar number of transition metals is 2mol), and then Weigh 2 mol of sodium carbonate to prepare a 2 mol / L solution, use ammonia water as a complexing agent, slowly add the three solutions into the reaction kettle, react at 55°C for 12 hours at pH = 8, filter to obtain a precipitate, and vacuum dry to obtain carbonic acid salt precursor;

[0076] S2, mix and stir the carbonate precursor and lithium carbonate (the molar ratio of precursor and lithium source: 1:1.05) with absolute ethanol as solvent until the solvent evaporates completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com